Technical Standards: Benefit or Hindrance to Progress?

Technical standards are meant to protect the safety and welfare of the general public by providing uniform product design and performance requirements for the manufacturer. However, when narrowly written, a standard can unnecessarily impede technological improvements and restrict competition in the marketplace.

Technical standards, such as those published by ASTM International as well as Canadian Standards Association (CSA), communicate consistent methodologies for product design, testing and verification that ultimately protect the consumer. Manufacturers use these standards as guides to design and manufacture products that meet the industry’s demands. Engineering plans, contracts, and government regulations incorporate and reference these standards for consumer protection. Consumers of products manufactured to ASTM or CSA specifications can rest assured they meet the highest standard in design, testing and manufacture.

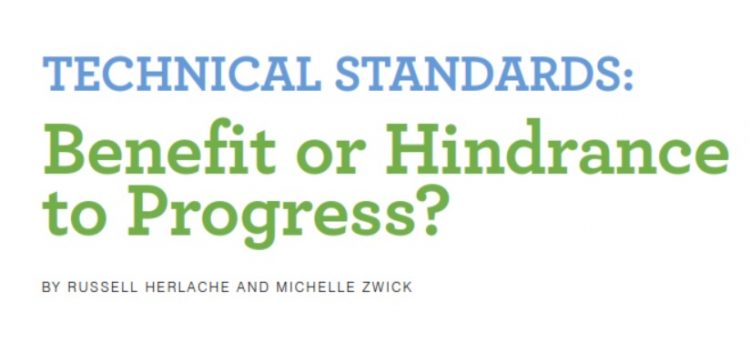

When the marketplace calls for a new technical standard, whether due to product deficiencies or the introduction of a new technology, standards bodies such as ASTM and CSA begin the process of drafting these standards by selecting representatives from the groups shown in Figure 1.

Figure 1. Standards bodies select representatives from these committee voting categories.

The committee comprises individuals with special interest or specific knowledge of the product, design, test method or end use. The project lead will offer a draft standard; and then the committee will begin to review, edit and comment, and eventually ballot to the membership.

Within CSA, the technical committee will meet as often as necessary to discuss concerns with or edits to the starting draft. After the technical committee agrees upon the language within the draft, the standard undergoes a public review. The technical committee then addresses any public comments, and the standard is subsequently balloted internally. The chairperson of the technical committee will respond to any comments or negatives. If no further edits are required, CSA will conduct a final review and publish the standard.

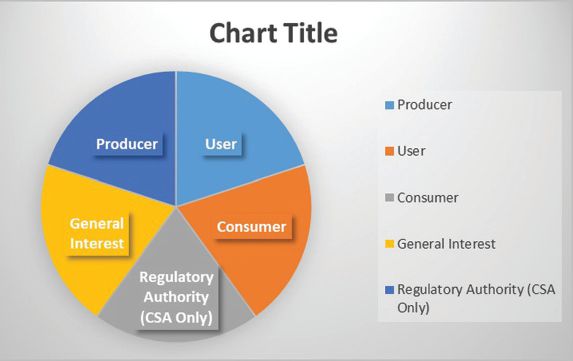

The ASTM structure organizes individuals into committees and subcommittees, and allows voting rights based on their designation as a user, producer, consumer or general interest. The individual bringing forth the need for the new standard forms a task group, recruiting any interested parties and subject-matter experts. After the task group creates the draft, the task group chair manages the comments and edits among the group until there’s a majority consensus that the draft standard is acceptable for balloting. However, consensus isn’t required.

Figure 2. A flow chart of the ASTM standard-creation process.

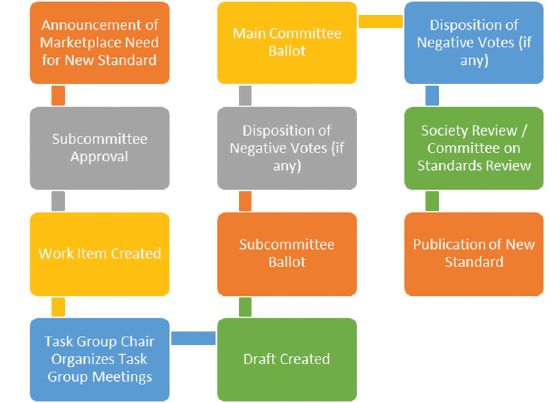

At the subcommittee level, a valid ASTM ballot requires 60 percent return, and two-thirds affirmative. If this is achieved, the draft may be balloted at the main committee level. The standard must undergo at least one subcommittee ballot prior to moving on to a main committee ballot. A successful ballot in the main committee requires a 60 percent return rate with 90 percent voting affirmative. At both levels, negative votes must be considered and dispositioned. The task group chair must address all negatives, either by working with the negative voter and agreeing on a solution, or through asking the committee to vote the negative not persuasive. ASTM requires one of the following dispositions seen in Figure 3.

Figure 3. ASTM voting options.

One negative voter with a technically valid reason can considerably halt the process. If a negative is considered persuasive, the draft must be edited and re-balloted, opening the door to additional comments and concerns by the subcommittee that didn’t surface previously.

Intent and Influence

The intent is to have a fair balance among these voting groups to ensure no group has an overwhelming presence to sway the standard’s direction and intent. In some cases, however, manufacturers can have significant influence in the creation of and revisions to these standards because of the following:

1. Knowledge of the specific product line and end use.

2. Knowledge of existing material and product-manufacturing techniques.

3. The desire to protect their position in the marketplace.

Undue influence on the part of existing manufacturers can impede the progress of standards development, which should be aimed at continuous improvement for manufacturers, end users and the general interest (i.e., the public). Some existing standards simply impede the use of new and improved technology, and thereby negatively affect product performance and cost for end users.

Design vs. Performance

Standards exist in two basic forms: design-based requirements and performance-based requirements.

Design-based standards may impede the use of products utilizing alternative processes or materials with improved performance and/or lower cost, or create unnecessary (and sometimes unfair) barriers to competition in the marketplace.

In an ever-expanding global marketplace, improved international coordination and development of standards can be achieved while minimizing the need to revise existing standards or create new ones. There needs to be a balance of design-based standards along with performance-based standards for the following reasons:

1. Design-based standards don’t take into account the likelihood of improvements in design, materials and use.

2. Design-based standards may not provide a cost benefit to the end user, because competition is impeded by hindering the development and use of applicable new materials and processing technology.

3. Design-based standards favor maintaining the “status-quo,” in part because there’s limited incentive for product improvement for the industry due to the hurdles associated with modifying existing standards to allow for changes in design and process alternatives.

A standard should have a balance of performance-based and design-based requirements. For example, design-based specifications are essential for the following:

1. End-user product requirements for comparisons of the interface with existing infrastructures.

2. Assurance that the interface of existing and future products will be compatible, as necessary.

3. Competitive quotation processes to maintain fair market principles.

Design-based specifications are essential for the successful development and implementation of any product, because they provide quantifiable elements such as capacity, applicable interface sizes, load-bearing capabilities, expected life of the application and known environmental issues.

All manufacturers need to know what is required in terms of quantifiable elements, such as the expected lifecycle, structural (load-bearing) requirements, environmental compatibility and the interface with existing infrastructure. At the same time, the direction on how products are to be made must not impede innovation. The door needs to remain open for innovations in materials, manufacturing processes, design techniques, and end-user installation to maintain fair competition and continuous improvement in the marketplace.

A Case Study Reveals Potential Problems

CULTEC was an active participant in creating both of the CSA and ASTM standards applicable to its stormwater chambers, which compete against other products typically manufactured by the plastic injection molding process. These structural foam products provide the same structural performance, but at a lower cost due to its reduced material content. This same product was third-party certified to CSA B184, the performance-based Canadian counterpart to ASTM F2418. The CSA standard uses the same performance criteria as ASTM, however, with limited restrictions caused by unnecessary design requirements.

On the other hand, the Standards Committee within ASTM deemed CULTEC’s process—foam injection molding—to be outside the scope of ASTM F2418 because of the chamber’s lower-density structural foam wall. Its product was made from the same material as specified in ASTM F2418 and met the same end-use performance requirements. Furthermore, the committee was unwilling to simply modify the existing standard to allow for the alternative process technology. The standard includes a classification table of product dimensions of those products that have been proven to meet the standard. CULTEC had the option to state conformance to the performance requirements of the ASTM standard, but inclusion of the CULTEC products was denied, placing CULTEC at a disadvantage within the marketplace.

A CULTEC product was certified for a CSA standard but not by ASTM, although the same performance criteria were used.

In January 2020, CULTEC successfully balloted a new standard with ASTM International, ASTM F3430-20 Specification for Cellular Polypropylene (PP) Corrugated Wall Stormwater Collection Chambers. The time to develop this standard, although 95-percent similar to ASTM F2418, cost CULTEC two years in the marketplace.

Some may view this as a tacit way to restrict competition in the marketplace. It’s disappointing that structural foam products couldn’t have been included in the existing F2418 standard, because the product performance requirements are the same for structural foam chambers, and they compete in the same marketplace. Any additional requirements—such as density and the associated quality-control methods—could’ve easily been handled in a revision to the existing standard.

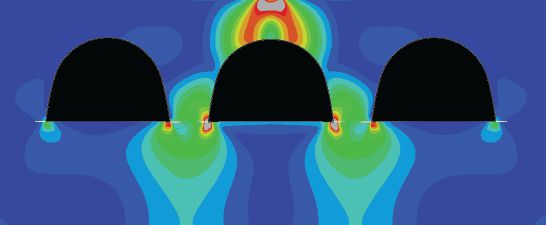

To prepare for a standard-approval process, CULTEC put its chambers through a finiteelement analysis. (Credit: Stress Engineering Services)

Some users could wrongly interpret that a structural form chamber is too different from (and possibly inferior to) the competing products, because it doesn’t meet the long-established ASTM F2418 standard. In addition, it can create confusion in the marketplace, because ASTM standards are frequently used in the quotation process. In other words, compliance of chambers to ASTM F2418 may be specified, which could disallow the use of a product which meets ASTM F3430-20.

Changing the Rules During the Game

Another shortcoming in the ASTM process was evident in 2016 when an alternative chamber manufacturer sought conformance and inclusion in an ASTM standard. The original ASTM F2418 standard was published in 2004; in 2012, the drafter of the standard balloted a change to include new chamber dimensions. Later, the drafter balloted another change to modify those dimensions because they made a slight modification to the size of their product.

Meanwhile, an alternative manufacturer of stormwater chambers developed a chamber with the same dimensions originally included in the standard. By the time they tested the chamber and were ready to state conformance to and request inclusion in the standard, the standard no longer included the dimensions of the product they so diligently designed and tested. To state compliance with the standard, the manufacturer had to re-ballot the standard to include dimensions that previously existed in the standard and undergo scrutiny by the subcommittee. If the standard never included the dimensions in the first place, this extra step could have been avoided.

Balancing the Process

Improvement to the standards process will only come when more individuals take a balanced approach between performance and design. For those ready to take on the standards process, valuable lessons to consider include the following:

1. Have an excellent understanding of what’s really needed for the end user for product performance.

2. Thoroughly review existing standards and determine if the product falls under the jurisdiction of an existing standard.

3. Encourage a fair balance of committee membership to best serve the ultimate customer: the general public.

4. Provide for flexibility in standards so revisions can be minimized while still meeting essential and necessary performance requirements.

5. Compromise as necessary to ensure fair and balanced competition. The customer is ultimately the key stakeholder.

6. Encourage and foster continuous improvement in products so the desired health and safety of the public are achieved at a competitive and reasonable cost.

7. Seek the advice of the committee on how to pursue approval.

8. When changes to an existing standard are necessary, construct the revisions in such a way to be open to continuous improvement for all involved.

9. When possible, draft standards that use a performance-based structure rather than a specification-based structure to minimize the need for future revisions due to technology advancement.

Standards aren’t meant to provide a competitive advantage to one group or another. They’re meant to provide clear direction within the industry for what’s necessary to accomplish the following:

1. Provide for the health and safety of end users and the public.

2. Ensure, as best as it can, open and fair competition in the marketplace.

3. Allow for changes and improvements in technology.

Standards require continual development, monitoring and revision where appropriate to ensure that all of us—the general public, end users and manufacturers—are provided with a healthy and safe environment

at a reasonable and cost-efficient level.

About Russell Herlache

Russell Herlache is a technical consultant to CULTEC Inc.; email: [email protected]. Michelle Zwick is a quality assurance engineer with CULTEC Inc.; email: [email protected]. Both are active members of the ASTM and CSA Standards Committees associated with stormwater management systems.