A Big Deal by Any Measure: Gerald Desmond Bridge Replacement Opens for Business

Currently clunkily named, but impressive by every other measure, the Gerald Desmond Bridge Replacement opened all six vehicle lanes to traffic on Oct. 5, 2020, marking the triumphant conclusion to a seven-year, $1.47-billion project that may well turn out to be the most significant and successful infrastructure achievement in California this decade. Headlining superlatives include the following:

• With two towers reaching 515 feet into the sky, it will be the second-tallest cable-stayed bridge in the United States, with the highest vertical clearance (205 feet) of any cable-stayed bridge in the country. For comparison, the cable-stayed Arthur Ravenel Jr. Bridge in Charleston, S.C., has the tallest towers at 572.5 feet, but the deck is “only” 186 feet above the water.

• A showpiece of the latest seismic technology (logical given California’s earthquake history), the new bridge is designed to survive events of greater magnitude than projected, not by being super strong, but by “failing” in easily repairable ways. It’s also designed for a 100-year lifespan.

• The new bridge is built with 18 million pounds of structural steel, 75 million pounds of rebar and 1.7 million feet of cable. And all this nearly 100 million pounds of steel was made in the United States.

A Long-Needed Replacement

Here’s a fun bit of infrastructure trivia: the Gerald Desmond Bridge, now being replaced, was itself a replacement of an unnamed pontoon bridge constructed in 1944 to accommodate traffic resulting from the World War II expansion of the Long Beach Naval Shipyard. Although intended to last just six months, the “temporary” pontoon bridge was actually in use until 1968. It could accommodate marine traffic by literally breaking apart, but this was of course mightily inconvenient for both marine and terrestrial vehicles. It also must have been disconcerting for the cars and trucks that had to descend 17 to 25 feet (depending on tide) to the floating bridge deck, as evidenced by the seven people who died after driving off the bridge.

Bonus movie trivia: The pontoon bridge (just a half-hour’s drive from Hollywood) was featured in the 1963 film It’s a Mad, Mad, Mad, Mad World.

As obviously bad, inadequate and dangerous as the pontoon bridge was, replacement was still an extremely difficult political proposition. Acquiring approval and funding was so difficult, in fact, that the new bridge was named after the prominent Long Beach City council member and city attorney who pulled it off. Perhaps due to a lack of political will at the time—perhaps also due to a lack of earthquake and port-growth prophets—the 1968 five-lane, through-arch bridge was barely adequate for purpose when opened, and within a few decades already struck most as under-engineered. For example, steep approaches and a lack of emergency/breakdown lanes meant that accidents on the bridge would shut down traffic for hours.

Some mitigation work was done, including substantial seismic retrofitting in the late 1990s as well as the addition of nylon mesh “diapers” in 2004 to catch chunks of concrete falling off the bridge’s underside.

Yes, by 2000, the Gerald Desmond Bridge concrete deck was spalling, flaking badly and, well, falling apart. The fundamental challenge afflicting the 1968 bridge was that it was designed for relatively modest traffic. Unfortunately, when the Long Beach Naval Shipyard closed in 1997 and was quickly converted into one of the busiest container terminals in the United States, bridge traffic (already impacted by port development and significant oil industry) soared—by some estimates, truck traffic across the bridge tripled in just a few years, quickly rising to 15,000 trucks per day. And from there it got worse; by 2002, thanks mainly to increased imports from Japan and other parts of Asia, the ports of Long Beach and Los Angeles were handling 39 percent of U.S. container imports, and by 2010 port officials estimated that 15 percent of all waterborne cargo in the entire United States passed over the Gerald Desmond Bridge.

The new “Bridge Replacement” (left) towers over the decades-old Gerald Desmond Bridge (right).

Marine traffic also was impacted, mainly because the new bridge wasn’t designed with container ships in mind. For one thing, bridge clearance was only 155 feet, and by the 1980s many cargo vessels required about 200 feet overhead.

“This was in the 1960s, before the fundamental importance of large container vessels to shipping was really recognized,” says Duane Kenagy, capital programs executive for the Port of Long Beach and project lead for the replacement bridge construction project. “As a result, the bridge wasn’t built to accommodate the kind of port traffic that became common within a couple decades. And since we have two ports here—the largest port complex in the United States by a large margin—that was a problem.”

In 2007, Caltrans rated the structural sufficiency of the Gerald Desmond Bridge at just 43 points out of 100.

“It was what they call ‘functionally obsolete,’” notes Kenagy. “Not falling down, but not really serving modern needs, either.”

As a final indignity, the 1968 bridge was never considered especially attractive; the through-arch design was functional and quaint in appearance, rather than strikingly modern, and the United States’ largest port complex surely deserved an aesthetically impressive bridge.

Bonus movie (and video game) trivia: The actual opening ceremony of the Gerald Desmond Bridge was the major set for the opening scene of the peculiar, psychedelic-cult-classic Monkees movie Head as well as the setting of the movie’s conclusion. It also features in the 2013 video game Grand Theft Auto V.

The previous Gerald Desmond Bridge (above) was already having difficulties keeping up with current cargo ships and wouldn’t have near enough clearance for future designs.

Given the functional obsolescence (and the diapers), it’s no surprise that talk about a replacement started early—just a couple of decades into the bridge’s life.

“The idea of a replacement bridge came up in the 1990s,” adds Kenagy. “Driven by several factors, particularly the bottleneck it had become for truck traffic and the limitations on large container vessels due to low deck clearance. I’d say serious investigation began in 2000, because here in California planning for megaprojects takes a very long time, and there were a lot of questions to answer.”

Major questions included the following:

• Given the many inescapable restraints, just what type of bridge to build? And what should it look like?

• How does one support a massive bridge in a massively unstable and actually subsiding ocean floor, while working around old oil wells and fields and other developments? “It was like remodeling a house while still living in it,” says Kenagy. In fact, the new bridge crosses the Wilmington Oil Field, active since 1932, where more than 6,000 wells have been drilled and 600 wells remain active.

• How does an entire new bridge get shoehorned into an already inordinately crowded port complex, while keeping the old bridge in place and in service while the new bridge is being constructed? “Keeping the existing bridge open during construction was always a project requirement,” emphasizes Kenagy. “After all, the cargo passing over the bridge was a major economic engine for the entire United States, and traffic was increasing all the time. 2017 and 2018 were record years, and the last quarter of 2019 was also a record.”

• How does one keep a bridge standing, and hopefully open, during and after major earthquakes? After all, California is the second-most seismically active state—the first is Oklahoma, where earthquake activity has increased dramatically in recent years due to … oilfield activity such as that of Long Beach Harbor.

• And let’s not leave out the biggest question of all: How does this thing get paid for?

The answers to these questions would fill a book, and let’s hope that book is written someday. But for now, let’s skip a stone across the surface with a quick look at some of the notable innovations and solutions deployed in Long Beach.

Firsts for California

Designed and engineered by Arup, the new bridge, with its 2,000-foot-long span, is California’s first long-span cable-stayed bridge. The twin, 515-foot, mono-pole towers anchor 40 cables each, which fan out on both sides from each tower top along 1,000 feet each; 500 feet of back span and 500 feet of main span. Visually, it’s as strong and light and seemingly inevitable as an avian skeleton, an elegant modernist jewel that somehow contrives to look perfectly at home on the drab industrial plains and utilitarian waterways of the port complex.

Much of that elegance is due to a lengthy and patient refinement of subtle details. For example, the geometry of the towers was the result of an extended iterative-design process that began with a simple elongated conical design similar to the 978-foot towers of Hong Kong’s Stonecutters Bridge (the world’s longest at time of completion, and also designed by Arup). After review, Arup principals decided that, “given the shorter height of the Gerald Desmond Bridge Replacement Project towers, such a specialized formwork system would not be economical.”

Therefore, two different solutions were considered: 1) a modified cone with constant-radius corners and a tapering flat section, and 2) an eight-sided geometry transforming from an octagon base to a square form at the top. Ultimately, the octagonally based towers were built, with the transformation to square top accomplished by “tapering four of the eight sides while maintaining the other four at a constant dimension.” This provided good-looking and functional towers that could be built cost-effectively. This painstaking workflow is illustrative of the attention paid to both function and aesthetics throughout the project.

Regarding the difficulties of squeezing massive infrastructure onto a difficult site, Kenagy says, “It was a challenge to survey and assess for sure, particularly right around the bridge, which was the heart of the oilfield. Back in the 1940s and 1950s, so much oil was removed that the whole area subsided until groundwater injection stabilized it. But there’s still a nearby power station [NRG’s Long Beach Generating Station] that’s 13 feet below sea level—it wasn’t built that way!”

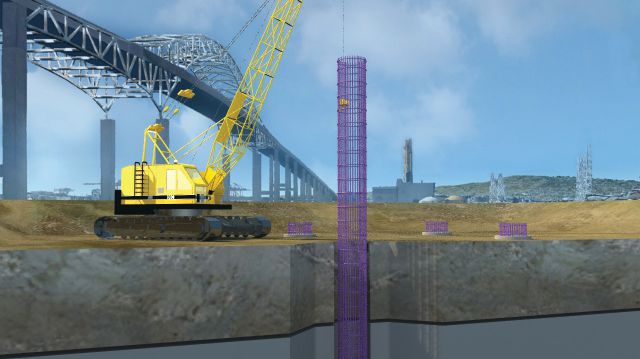

One thing survey and geotechnical work established was that piles typically employed as bridge supports likely wouldn’t be adequate in the soil conditions prevalent at the new bridge location. Instead, tip grouting, or a cast-in-drilled-hole (CIDH) grout-delivery system—“pressure grouting below the tips of drilled shafts in cohesionless soils”—was used on this project, another first for California.

The following is from the abstract of the paper, “Mobilizing CIDH Pile Base Resistance on the Gerald Desmond Bridge Replacement Project with Tip Grouting,” (Proceedings of the 40th Annual Conference on Deep Foundations, 2015, Oakland, CA, USA, (DFI)):

“Before this project, tip grouting has not been utilized on or accepted by Caltrans to maximize piles end-bearing capacity. This project proved that tip grouting to mobilize reliable base resistance can be successfully implemented on a full-scale bridge project requiring over 350 large-diameter shafts.

Some of the bridge’s 350 piles extend 17 stories underground to maintain stability in a subsiding ocean floor as well as safety during seismic activity prone to the area.

“For the Gerald Desmond Bridge Replacement Project, Shimmick/FCC/Impregilo, JV utilized a temporary Oscillator casing to the full depth to install CIDH piles. Piles were constructed by the wet method and then pressure grouted below the pile tip. A tip grouting procedure for these large-diameter shafts was developed and tested to specifically address the geology and constraints of the project … By tip grouting, the length and diameter of the piles were significantly reduced.” (emphasis added)

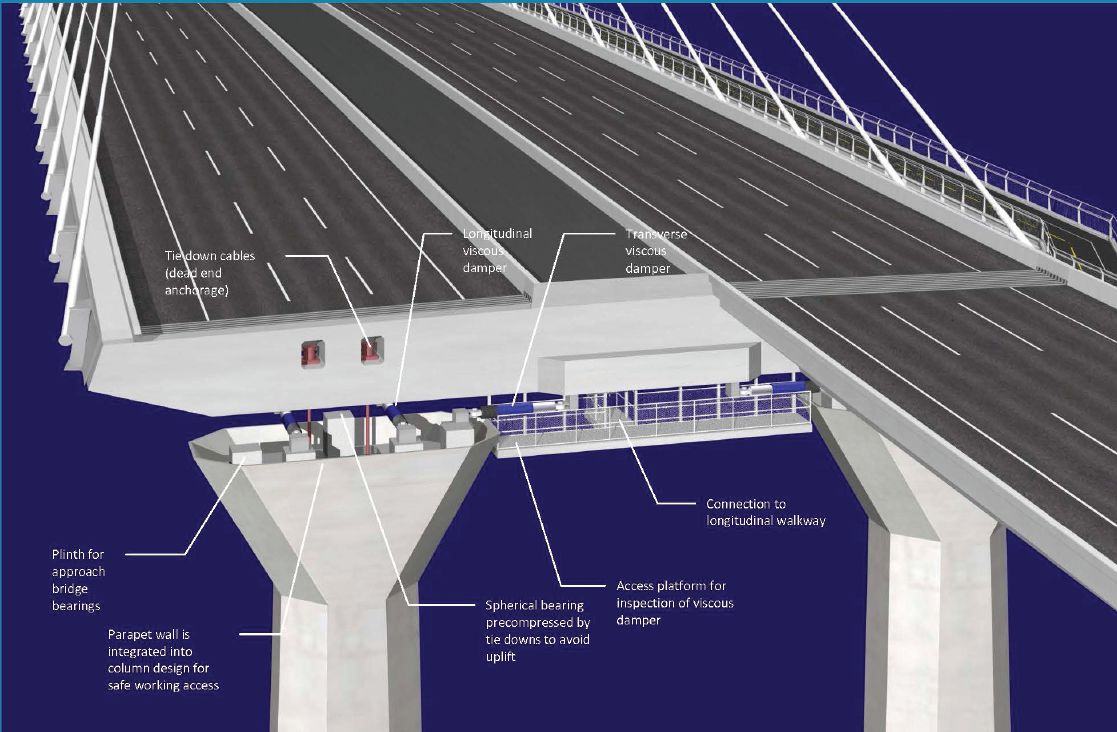

By contrast, seismic resilience built into the Gerald Desmond Bridge Replacement isn’t really cutting edge, though it is “state-of-the-art Type 3 AASHTO global seismic design strategy.”

“There’s not anything done here that hasn’t been done before,” explains Kenagy. “What’s really been done is that a number of best practices have been gathered for the first time.”

The new bridge’s seismic features are intended for “two different levels of earthquake,” the first (based on extensive analysis of local historical events) being the maximum event expected within the projected lifespan of the bridge, and the second, what might be called a “1,000-year earthquake,” an unlikely but conceivable extreme event.

The new bridge is built with 18 million pounds of structural steel, 75 million pounds of rebar and 1.7 million feet of cable.

Some of the more-conventional seismic features are intended to, as expected, absorb shocks—the 350 piles mentioned earlier, some of which extend 17 stories underground, are custom-designed to absorb the majority of a large earthquake’s initial energy waves. Others, such as the “end bents” connecting the east and west approaches to the main span of the bridge, are more or less intended to “break” and be easily repaired when called into service. The end bents (which are another first for California), designed by the German firm Maurer and built by Ohio-based D.S. Brown, enable controlled-swivel movements of up to 6 feet in three directions (vertical, longitudinal and lateral) at these junctions to compensate for movements between the adjacent structures. Interestingly, this flexible shock absorption is never called on during normal operations; instead, per Arup:

“The viscous hydraulic dampers will only activate during a major earthquake. An integrated structural fuse, or a solid piece of steel that connects the damper to the tower, will break at a force corresponding to the considered magnitude. After the steel fuse breaks, the viscous dampers begin to dissipate cyclic energy the same way that a car’s shock absorbers do on a bumpy road. The fused design prolongs the lifespan of the absorbers, as they remain inactive until there is significant seismic activity.” (emphasis added)

Even better, once tripped, the fused dampers are designed to “fail well,” and are readily accessible and easily replaced in a process that could take place within hours of a major earthquake.

Compared to the design and construction, funding was relatively straightforward, although it depended on California’s first major design-build contract. Controversial at the time, but now judged a success, one wonders if the new facility might be named “The Long Beach Design-Build Bridge.” (It does have a certain ring to it!)

Renderings show some of the key and innovative engineering techniques used to construct the new bridge.

Actually, Not Quite Done

The new bridge (which will be named by legislative action after formal transfer to the state) is operating at full capacity, but there are a few “punch list” items yet to complete. “The bikeway, for example, is still being used for construction access, some surface street changes are still being worked on and there are detours to be removed,” notes Kenagy. “And though the roadway lighting is fully functional, architectural lighting is still being completed.”

Kenagy adds, fervently, “Whenever I talk about this project, I like to emphasize that this project has been monumental for the port, and the contribution of literally thousands of workers—from early design through all the work by tradesman and contractors that did a lot of hard work—should never be overlooked. This bridge would not exist without them!”

About Angus Stocking

Angus Stocking is a former licensed land surveyor who has been writing about infrastructure since 2002 and is the producer and host of “Everything is Somewhere,” a podcast covering geospatial topics. Articles have appeared in most major industry trade journals, including CE News, The American Surveyor, Public Works, Roads & Bridges, US Water News, and several dozen more.