Automation Is Coming to Your CMT Lab

In the field, technicians sample fresh concrete and cast cylinders to cure in the testing lab.

Specimens tagged by hand. Results written on clipboards. Data entered, line by painstaking line. Materials testing has always been overly manual. Then COVID-19 happened.

The traditional construction materials testing (CMT) workflow is, unequivocally, a human-dependent process. Humans write things down. Humans hand things off. Humans read what’s been recorded by other humans. Pretty much every step of the way, a human must get involved to move the show along.

This manual workflow, which is inefficient and error-prone, has for many years been the status quo for testing labs, manufacturers and others. And so, despite technological strides in automated machinery and software, the construction industry has unsurprisingly fallen behind the rest of the very-automated modern world.

But in a post-COVID-19 reality, what used to be considered “optional” or “nice to have” now is an existential requirement. Everyone who depended on CMT results has had to shift gears to socially distance and access key project data from home. Modern labs that have embraced change, moved to the cloud and leveraged technology to streamline manual workflows have had remarkable success keeping up and recovering losses from the onset of the pandemic. The labs stuck in the past … not so much.

The good news? The modern lab is more accessible than ever. Any testing lab can replace outdated processes with automation. The only way to solve productivity, profit and accuracy problems is by migrating the materials testing workflow to the cloud.

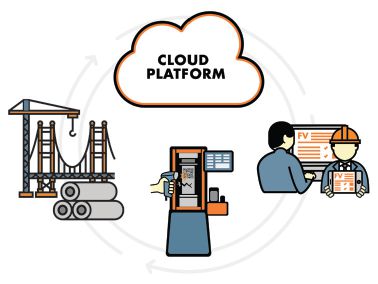

A cloud-based CMT platform helps labs carry out the entire testing process, from specimen identification to data analysis, so labs can save time and get more done faster with fewer people (and less risk). Here’s what this modern lab looks like—and why it matters.

The Modern Lab: Truly Automated Testing

Truly automated testing is all about eliminating manual influence from the CMT workflow—from the time specimens are created to testing to results dissemination and storage.

Truly automated testing can be defined as a CMT process or workflow that’s free from the bias of human hands. Without it—and the platforms that enable it—you invite the potential for human interference into dozens of failure points. This exposes your lab and employees to serious legal and financial risk. It also exposes your employees to the risk of human transmission of COVID-19 and similar future hazards.

To see why modern matters, let’s examine different levels of automation in CMT:

Manual Testing

For years, CMT was conducted on manually operated machines. Specimens were labeled with markers. Load settings were adjusted by hand. Results were recorded and transferred manually. And significant test detail generally went unrecorded.

But fully manual testing is tedious, time-consuming and vulnerable to human influence. This prompted the industry to incorporate a bit of automation into the workflow, leading to the next level: semi-automated testing.

Semi-Automated Testing

Up until recently, the industry standard in materials testing has been some version of “semi-automated testing.” This differs across organizations, but in a semi-automated testing workflow, you typically see one or both of the following components:

1. Automatic Machine

Instead of a manually operated machine that requires the skill, attention and time of a technician, many labs installed automatic machines that allow you to preload and run the test with the push of a button.

A single technician is more efficient, because he or she can run multiple machines or can perform other work while the test is running on a single machine. Automatic machines are a significant step in the right direction.

2. LIMS, Custom Software or Database

Many labs have graduated from a paper-based system to a database that’s either homegrown in Excel or part of its Laboratory Information Management System (LIMS). Labs that utilize these tools can record, visualize and report on results more efficiently. But technicians still spend time writing or typing. Even a system that pulls results off of the machine requires human effort to identify which results belong to which specimen.

Automatic machines and LIMS packages are vital to semi-automated testing, but there still are steps in the workflow that require human intervention. For instance, technicians have to manually label specimens and make sure to bring the right specimen to the right machine on the right day. This is because the machine doesn’t “know” what it’s testing, and the setup and control are entirely dependent on the technician. Finally, technicians also have to transfer and enter data manually from the machine to their LIMS or database.

This means there’s still plenty of opportunity for error—and exposure to risk. But that’s no surprise. Because, as the name implies, semi-automated testing is not truly automated testing. For this, some key adjustments need to be made.

Truly Automated Testing

Truly automated testing provides a testing environment in which data can flow seamlessly. Human hands only interfere at three touchpoints:

1. Preparing the specimen

2. Determining the specimen parameters for testing

3. Physically loading the specimen into the machine

Data entry only happens at the beginning of the testing process. The rest can run seamlessly.

1. At the push of a button, your automatic machine runs the test.

a) If any parameters are off or abnormal for the chosen specimen or sample, your machine will flag the test, asking you to double-check if everything is correct before proceeding.

b) If any parameters are impossible (e.g., a parameter is greater than the capacity of the machine, etc.), the machine will not let you press the “start test” button.

c) If you inadvertently attempt to run a test on the wrong day, the machine will warn you and require confirmation before proceeding.

2. After the test, the machine automatically transfers the results, first to a cloud-based database and subsequently passed along to your third-party database or LIMS.

Lab-test reports can be accessed anytime in a secure, unalterable format.

This creates an unbreakable link between your machine and a searchable testing database that contains results, project data, test setups and untested specimen data.

Although technicians still have to physically bring the correct specimen to the machine on test day, truly automated testing provides a benefit that’s not possible in a semi-automated or manual configuration: if you bring the wrong sample on the wrong day, your machine will know it’s wrong and prompt you with a warning.

How is this possible? In a modern testing process, the sample or specimen parameters live in a cloud database and are tied to a unique identification number. A barcode that contains this ID then is applied to the specimen. When a technician takes the specimen to the machine, he or she can scan the barcode on the label, and the machine automatically recognizes the specimen, including age and expected strength.

For these reasons, truly automated testing now is the standard in CMT.

An operator scans a QR code on a concrete cylinder’s label as it’s placed in the testing machine, making the machine “smart.”

Why Truly Automated Testing Matters

What’s the real impact of this process? Why does removing human hands matter? It all comes down to removing variance.

Variance measures the spread of a dataset. The higher the variance, the more the numbers in the dataset are spread out. In CMT terms, this means results are all over the place—not good.

Every human interaction within a process introduces inherent bias and variance. In fact, many ASTM procedures have been specifically designed to reduce this bias. But they’re limited where human interaction is concerned. The ideal state for an engineer is minimal variance, which naturally means minimal human interference.

The mission of eliminating variance can be broken into three core pieces: accuracy, productivity and transparency.

Improving Accuracy

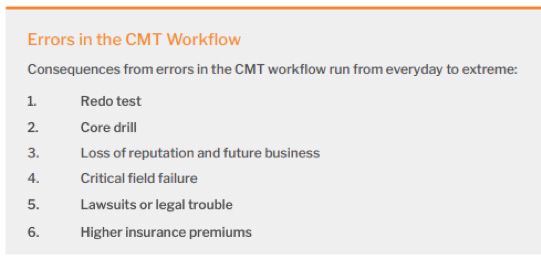

The sad reality is that humans make mistakes. We make small mistakes that compound into larger ones. We preload too high or too low. We rush and skip a step. We write numbers down incorrectly. We smudge Sharpie. We lose paper.

Sometimes, our mistakes are just noise in data and, for the most part, insignificant. Other times, it can become an operational risk. At the extreme, it costs not only jobs, but lives.

Eliminating human interaction improves accuracy simply by virtue of robotic precision. This isn’t to say that software and machines should replace humans—humans still have to manage the testing workflow—but with truly automated testing, the majority of accuracy issues can be mitigated.

Boosting Productivity and Profits

Most people can only do one thing at a time. Lab technicians are no different. Every number entered into a spreadsheet is a non-zero number of seconds or minutes. Every test run on a manual machine is time not spent preparing another sample or analyzing data. All of this affects a lab’s productivity.

Consider the impacts of COVID-19: Due to cost-cutting layoffs and social-distancing requirements, there are fewer workers available to carry out the manual process. Productivity (and profit) are even more of a concern.

Truly automated testing allows a lab to optimize technician time and shift focus to more-strategic tasks. This means conducting more tests and taking on more clients. And in an industry where time and margin are always in short supply, it makes your lab more competitive.

Automatic machines, which produce more-consistent test results and allow labs to conduct more tests per day than a manual machine, play a crucial role.

Promoting Transparency

Labs must be able to stand behind their work. They must be able to prove they tested, checked and recorded results correctly. This is why truly automated testing is a disruptive force for good in CMT. Because unlike labs that follow a semi-automated testing configuration, truly automated labs can prove their work.

In an environment of biased data, or even falsified tests, transparency has never been more critical. Truly automated environments provide an unbreakable, permanent record when a regulator wants to see detailed test results to verify compliance.

Ready to Modernize? Here’s How

A modern lab’s top priority is eliminating as many manual actions from the testing process as possible. Without an integrated, cloud-based CMT platform, there’s no way to automate the connection between your testing machines and LIMS, from sample creation to data transfer. Human hands have to intervene.

Here’s what you need in a CMT platform to modernize:

1. Private Cloud-Based Database

First, you need the cloud. This isn’t just any piece of cloud technology. A cloud-based platform is defined by free-flowing data that can be integrated to work with other software programs. This differs from cloud-based storage, which, while valuable in other contexts, is defined as flat files shared on a server and manually organized into a folder structure.

A cloud-based database provides structure for any lab’s testing, analytics, access and security needs. Results are accessible by authorized users from any device, at any time. Forever.

2. Open System

Leveraging a cloud-based platform doesn’t mean you have to scrap your existing software packages—so long as the platform you choose enables an open system. Your solution needs to play along well with other technologies so data can move freely between the cloud database, testing machine, LIMS, accounting system and more.

3. Short Learning Curve

Although COVID-19 has forced change, it still can be difficult to get people to change the way they’re used to working. Make sure any piece of technology you introduce to your lab transforms your process without making it more difficult to get the work done.

4. Technical Support

Lastly, implement a solution that’s backed by a provider with an experienced, dedicated team who knows the unique issues of construction materials testing … and exactly how to tailor solutions to meet your needs.

The Time Is Now

Truly automated testing reduces the risk of errors, increasing compliance and driving more-positive outcomes for labs of all types. In the world of COVID-19, this is the necessary new standard in the CMT space.

As COVID-19 subsides, the world will have moved beyond paper-based testing and data-management protocols. For testing labs that lag, it will be much more difficult to catch up. There’s no better time than now to modernize your CMT lab.

About Scott Grumski

Scott Grumski is vice president of Platform Development for Forney LP; email: [email protected].