Sewer Heat Recovery Provides Low-Cost Recycled Energy

In every urban area, heat that humans have generated to shower, wash clothes, cook, and so on flows underground — in the sewers, making them very warm. Today, sewers represent the largest source of heat leakage in buildings. Even toilet water, which is at room temperature, is warm compared to the ground. Sewer air, pipe material (and thus conductivity), surrounding soil type, and other factors also affect the final temperature of waste water, according to Genevieve Tokgoz, Project Engineer in the Research and Innovation Division in the Utility Planning Department of Metro Vancouver, Canada.

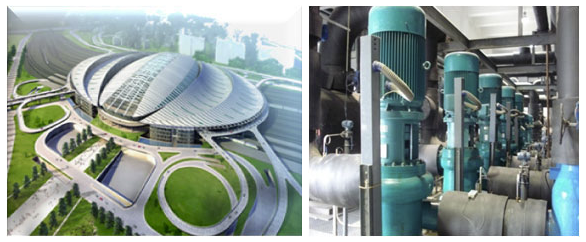

The 1 million sq ft Beijing Train Station that opened in August 2008 as a national technology showcase for the Olympics, is the largest building to date utilizing sewage geothermal.

(Source: Nova Thermal Energy)

A few municipalities have begun to recover some of this energy and to use it to heat and cool buildings. Vancouver used it to heat the athletes’ village for the 2010 Winter Olympics. Paris uses it to provide 10 percent of its energy needs, including heating buildings within about 600 feet of each heat exchange facility. Brainerd, a small city in Minnesota, is building a similar system in partnership with Hidden Fuels, a company based there, and thanks in part to a $45,000 grant from the federal stimulus package.

In April, Philadelphia-based NovaThermal Energy announced its first U.S. project to warm a building with heat from sewage. The building, the Southeast Water Pollution Control Facility, belonging to the Philadelphia Water Department, will house the 1 million BTU/hour unit in its basement, where it will directly access and transfer heat from an adjacent sewage channel.

Metro Vancouver is working on a long-term policy to enable system implementation of sewage heat projects. “We work on many resource recovery goals,” Tokgoz says, “so sewer heat is just one of the potential resources we are exploring. We are also looking at opportunities to recover energy from landfill gas and from our water transmission system.”

The Naneff Gardens Subdivision in Garson, ON, Canada is a 19-lot subdivision that is using @Source-Energy Pipes for the storm and sanitary sewers. Hookups to the energy are at the lot lines for homeowners to connect to a heat pump located inside their house – to provide heating and cooling.

(Source: Renewable Resource Recovery Corp.)

The technology is simple and proven. Wastewater energy installations are efficient and environment-friendly. The first were built more than 25 years ago and more than 500 wastewater heat pumps are in operation world-wide. Large scale implementation would not require any additional scientific research or technology development, but only education and some up-front investments. We already know that there is a resource there, points out Dr. John W. Lund, who has been researching and teaching geothermal energy for nearly 40 years and recently retired as a professor of civil engineering at the Oregon Institute of Technology.

“As long as it is somewhere between 30 and 90 degrees Fahrenheit, it can be used for both heating and cooling, using what we call a geothermal heat pump,” he says. “The higher temperatures work best in the heating mode and the lower temperatures work best in the cooling mode.” Generally, heat extraction does not involve contaminating the fluid, so this can be done with the domestic water supply, before it reaches faucets, as well as with sewage water. “These are known resources in the ideal temperature range,” says Lund. “It is just a matter of tapping into them, installing the heat exchanger, and connecting the heat pump to various buildings. So, the risk is minimal compared to other geospatial projects and the payback, in most commercial installations, is probably less than five years.”

Nevertheless, some experts are cautious. “Large scale heat recovery from municipal waste water streams is possible with current technology, but it would be more cost effective to conduct targeted research and development before committing large capital to these projects,” says Mark A. Shannon, James W. Bayne Professor in the Department of Mechanical Science and Engineering at the University of Illinois at Urbana-Champaign.

Advantages

Recovering heat from sewers is probably 30 to 50 percent cheaper than geothermal installations, which require either drilling holes in the ground and installing a closed loop system or drilling water wells that use an open-end system, according to Lund. Additionally, unlike furnaces, which provide only heating, geothermal heat pumps provide both heating and cooling. Heat recovery also reduces heat pollution in rivers, streams, and lakes, thus reducing the growth of algae.

Heat recovery can also be a source of revenue for cities. “When big cities replace their sewers, they never think of it as a way to recoup their investment, so there’s never been a business case for it” says John Hood, Vice-President of Research and Development at Renewable Resource Recovery Corp. (RRRC), based in Sudbury, Ontario, Canada. “They have to start realizing that they could produce energy, sell it, and use the profits to pay for infrastructure.”

Portland’s Brewery Blocks uses an industrial scale district cooling system, the predominant scale in the United States.

(Source: Washington County, Oregon)

Obstacles

Despite its feasibility, cost-effectiveness, and environmental advantages, sewer heat recovery is still in its infancy. One reason is that, in North America, energy is still relatively cheap, so demand for energy conservation and recovery is low, though that is starting to change. Another is that it requires some upfront investment and many state and local governments are in dire financial straits. The increasing need to upgrade aging infrastructure provides an opportunity to install these systems. However, often building codes specify that sewers be made with plastic pipe, because it is cheaper, points out Les Lisk, Vice-President of Finance at RRRC. “So, many of the specifications would have to change.”

Yet another obstacle is lack of awareness and education. “In Klamath Falls, Oregon, we have 600 geothermal wells,” says Lund. “My house is heated geothermally and so are schools, swimming pools, etc. But if you drove into town, you’d never know that geothermal was being used, because it is all underground, so most people aren’t aware of it. City engineers and public works directors probably have very little background in this area and are reluctant to mess with their domestic water or sewage system.”

“While the required technologies — heat exchangers, heat pumps, and screens — are not new,” says Tokgoz, “one of the main technical challenges is maintenance associated with clogging of the equipment. However, the City of Vancouver and their Neighbourhood Energy Utility, which uses raw sewage as a heat source, have operated these systems for a couple of years and have shown that they can be managed.”

Another important technical consideration, she adds, is the impact of withdrawing heat upstream on wastewater treatment plants, most of which utilize anaerobic digestion techniques. “There are still many unanswered questions about how much heat we can extract upstream before the inflow temperatures drop below desirable levels.”

The impact of withdrawing heat upstream on wastewater treatment plants, most of which utilize anaerobic digestion techniques, is yet unknown.

(Source:Flickr)

How It Works

Once a heat exchanger is installed, either all of the water is run directly through it or some of it is diverted to the heat exchanger and then back into the pipeline. “It is a very simple thing to do,” says Lund.

When building and installing heat recovery systems in sewers, there are two key engineering considerations: to avoid blocking the flow and to protect the heat exchanger from corrosion. RRRC addresses both issues by building sewer pipe segments that have heat extractor tubing within their walls, so that it has no contact with the effluent in the pipes. “From the outside,” says Hood, “you could not tell the difference between our pipes and a regular pre-cast concrete sewer pipe. With our system, you can have as much of a length of pipe as you want — for example, in front of a house. Each system is separated, so that each home has its own inlet and its own outlet. Although the sewer pipes are contiguous, the heat extraction system isn’t. So if, say, the heat extraction line were to break, it would not affect the next house at all.” Based on initial tests, this system can generate about 37,000 BTUs per hour per hundred feet, according to Lisk. “So, the number of BTUs you want determines the length of pipe you require.”

In a project due to start next summer in York, a municipality near Toronto, RRRC will divert the waste water to a parallel loop containing the heat exchangers.

Heat Mapping

The optimal location for the installation of a heat exchanger in the sewer depends on several criteria. First of all, it is important that it be close to the consumers of the energy recovered. For this reason, the possibilities for use that are economically most interesting are concentrated at places where wastewater is available both continuously and in large quantities, such as hospitals, factories, and high-rise residential buildings. Second, while wastewater temperature usually is highest in the initial part of the sewer system, more heat can be reclaimed from the wastewater if the discharge level is high, which is typically the case toward the end of the sewer. Finally, lowering the temperature of influent wastewater reduces the efficiency of nitrifying wastewater treatment plants. Therefore, the energy potential of cleansed wastewater is much higher than that of raw wastewater, because downstream from the sewage treatment plant it can be cooled down much more than upstream.

Unfortunately, in many places this large energy potential cannot be used because the sewage treatment plants are located outside residential areas, far from potential customers for the heat. Given these considerations, planning and designing a facility to recover heat from raw wastewater requires quantifying how wastewater temperature changes along the flow path in the sewer and the effect of heat recovery on the influent temperature of wastewater treatment plants.

Evaluating whether a heat recovery system would be cost-effective in a given area also requires inventorying the energy demands of nearby buildings, the types of heating and cooling systems that they already use, and the various sources of energy available. Several Swiss cities have compiled wastewater use maps that identify sewers suitable for heat extraction and note the amount of usable power. “You have to find out whether you have the load, that you can convert your existing heating system, and that it is economically competitive to do it,” says Lund. “Some places have natural gas that might be as competitive, in some cases, as installing a heat pump system.”

In large urban areas, according to Lund, it is not necessary to map the heat distribution in the sewers because the flow will be so great that there will be very little temperature loss. It is easy to measure the temperature in a few spots, he says, and, anyway, small temperature variations will not make a significant difference. However, says Tokgoz, “As a regional government, our role has been to respond to outside requests for access to our sewage heat. So, for us to understand how much heat is available at a specific location is critical for providing information to the potential heat users. We are in the process, right now, of collecting temperature data and that allows us to understand what the temperature is and how it fluctuates with the seasons or through the day. That is how we are able to estimate the quantity of heat available. We overlay that with demand data, by using land use planning data and information that we have about future development, to figure out where high density and high heat demand might be in the future. Then, we are able to see where some potential nodes and future sewer heat opportunities might exist.”

How detailed does the heat map need to be? “Developers who are building new systems want to know the hourly temperatures during the past five years because they want to be sure that the heat energy will be there when they need it,” says Tokgoz. “We are working toward completing a detailed understanding of where the heat is by installing temperature sensors in all of our sewage pump stations and then we will create maps on the basis of that information.”

How much temperature variation is there in sewers, typically? “Heat loss to the surrounding area will vary significantly,” says Shannon. “We have five different sewage catchment areas and we have seen a fairly significant difference in their average daily temperature,” Tokgoz says. “If you compare one of the waste treatment catchment areas that is right against our North Shore mountains with another one further down in the river valley area, the average daily temperature seems to differ by at least three or four degrees. Sewage temperatures will also vary between locations depending on whether the sewer carries combined sanitary and storm water or just sanitary sewage. Our data so far shows that combined sewers, as you might expect, have cooler temperatures.”

Philadelphia is working to replace their combined sanitary and storm sewer system that leaks sewage into local rivers during storms, a common problem of older cities in the eastern United States. Replacement of aging infrastructure opens the opportunity for capturing this low-cost energy source.

(Source: Philadelphia Water Department)

Economics

According to Lund, the economics of using heat extraction to heat and cool buildings favor larger commercial and institutional buildings over smaller residential ones. “In buildings under 1,500 square feet, the payback may take 10 to 15 years. In larger buildings, however, the economics are much more favorable. In most cases, the commercial or institutional public buildings become the leaders.”

It is often expensive to retrofit existing heating systems to use heat recovered from sewers. “Many water heaters in homes are steam heaters and they are too small to use hot water at 100 degrees or 120 degrees, so they would probably have to be replaced with larger ones, which is a retrofit cost,” Lund explains. “That’s the problem, of course, with heat pumps: they don’t provide high temperature water. Even a district heating system, from a fossil fuel power plant, might be providing water at 160 degrees or 180 degrees. Heat pumps are never going to do that; they are going to red-line at 115 degrees or 120 degrees. So, the existing heating system — radiators, forced air, what have you — are not large enough. That’s true of any heat pump system, when you are trying to retrofit. For new construction, however, that is not a problem. You can design it for the temperature, so you put in the right unit to do it in the first place.”

“Individual buildings don’t have a continuous supply of heat,” Tokgoz points out, “so they would have to incorporate some kind of thermal storage. Heat recovery from sewers, on the other hand, is likely more cost-effective because heat supply through the day is more continuous. You have demand for heat from commercial buildings during the day time and then from residential buildings mostly in the evening, so it is a nice balance with the amount of heat that is available. When you are looking at individual buildings, the requirements are unique — depending on each building’s size, its use, the amount of fluid available, etc.”

Return on Investment

According to NovaThermal Energy, wastewater geothermal energy efficiency technology saves up to 60 percent in building heating and cooling costs and a typical system costs $0.20/BTU/hour to $0.30/BTU/hour or $600-$900/kilowatt for equipment and installation, depending on heating loads and site. For the Philadelphia Water Department, the company has installed and will operate its smallest commercial scale wastewater geothermal system, operating at 978,000 BTUs/hour/60 cooling ton, to provide building heating in the plant’s compressor building. It says that the installation, which cost about $150,000 that was supplied by a federal stimulus grant, will save $216,600 over 15 years and is expected to pay for itself in eight years. “The project payback,” it notes, “is limited by the project scale, which would be accelerated by larger building loads, year-round or longer daily use.”

Estimated financial data from RRRC for a 100-lot subdivision shows a total cost of $577,000 — 83 percent due to the increased cost of the company’s @Source-Energy Pipe over common PVC pipe — and a revenue of $150,000 per year, which would pay for the project in 3.9 years.

State and local elected officials and public works directors ought to study these figures, which will no doubt improve with economies of scale as demand for energy savings and recovery expands.

About Matteo Luccio

Matteo Luccio has nearly twenty years of experience as a magazine writer and editor. He has a master’s degree in political science from MIT and co−founded the public policy magazine Oregon’s Future, which he edited for four years. For the past twelve years he has edited and written articles for technical magazines on geospatial technologies, the last five as president and founder of Pale Blue Dot.