Square Building in a Round Hole

Integrating virtual construction and geospatial technologies into design-build projects reduces risk and improves control costs.

It’s hard enough to build a complex industrial structure 12 stories tall. Putting the structure into a deep, concrete-lined hole is even more difficult. And then you’ll need to do it twice. That’s the challenge facing Abe Torres and his colleagues at PC Construction. When the job is finished, however, they will have helped solve a problem more than 200 years old.

The project is taking place in Washington, D.C., a busy, compact city that’s among America’s most-popular tourist destinations. The city’s resident population, large commuter workforce and millions of visitors each year can push demand for essential services beyond capacity. But crowds aren’t always the cause of the overloads: Mother Nature and aging infrastructure can combine to create a huge challenge to the city’s sewer system, which dates to the early 1800s.

Like many older cities in the United States, Washington’s sewer system collects sanitary sewage and stormwater into common pipes that carry water to a treatment plant. When heavy rains occur, the runoff exceeds the system’s treatment capacity, and these combined sewer overflows release untreated effluent into area rivers.

To help mitigate the problem, the District of Colombia Water Authority is building a series of massive tunnels that will capture and store runoff, and then feed the water to treatment plants in a controlled flow. The tunnels ultimately connect to the Blue Plains Advanced Wastewater Treatment Plant, where a new pumping station will lift the water from the tunnels and deliver it to treatment facilities.

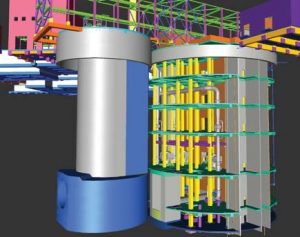

The tunnel into the Blue Plains plant is 5 miles (8 kilometers) long, 23 feet (7 meters) in diameter and roughly 170 feet (52 meters) below the surface. It connects to a pair of circular concrete shafts 132 feet (40 meters) in diameter that will contain the massive piping, pumps and equipment that make up the tunnel dewatering pump station. The joint venture of PC Construction and CDM Smith has a design-build contract on the pumping station and related facilities.

Torres describes the project as placing a 12-story industrial facility with seven levels of steel, mechanical and electrical components into a deep, round hole. The design and construction of such a large, complex facility is a prime opportunity to leverage building information modeling (BIM). By combining BIM with spatial technologies in the field, PC is achieving cutting-edge efficiency and significant cost savings.

3D Modeling Meets the Physical World

When Torres arrived on the project, another firm had already completed construction of the two shafts. The shafts’ concrete liners included beam pockets and keyways to support the new structures. PC needed to verify the dimensions and locations of these and other elements as well as compare them to the 3D model of the concrete structure they would build into the shaft. Torres suggested that 3D scanning would be a fast, cost-effective approach.

Using a Trimble TX5 scanner, PC crews scanned the first shaft, conducting 16 scans connected by control points attached to the shaft walls. After registering the scans to produce a single point cloud in Trimble RealWorks software, Torres could bring in the design model.

Using the scanning data, the design team merged field measurements with the 3D design model of the pump station and determined a best fit to place the structure in the shaft.

“We had to turn it a little bit—not much—and it came together pretty well,” notes Torres. “With the exact dimensions in hand, we figured that we could prefabricate our beams and steel. Crews can do much of the assembly outside, and then slide it into the hole and put it in place.”

The second shaft came with more challenges. Scanning revealed that the concrete liner was out of plumb in places, and the design would need some adjustments.

“Our rebar was going to be too long, and we needed to redesign it,” explains Torres. “Had we ordered rebar according to the original design, there was no way it would fit. Doing the scan and checking it against the model saved us a bunch of money.”

Checking the models and feeding up-to-date information to construction crews is a continuous process. Matt Harraka, a virtual design construction manager for CDM Smith, notes that engineers and designers use a broad range of software tools to develop structural, architectural, MEP (mechanical, electrical and plumbing) and grading designs.

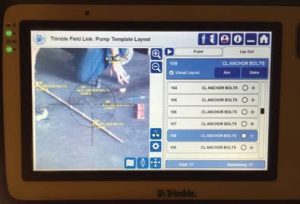

A PC surveyor is shown on the Yuma display. The surveyor is seen from the total station mounted on a bracket on the shaft wall (above the red ladder.)

Harraka manages dozens of different file formats to bring the designs together in large model viewer systems such as Navisworks or—for earthworks and surveying—Trimble Business Center software. PC uses Trimble Connect to manage and share design and construction documents with field engineers and subcontractors. As design changes occur, Torres uses Tekla software to manage the model and check for fit or clashes, placing updated files onto the Trimble Connect server. Then the data move to handheld field controllers for layout.

The controller display during layout of anchor bolts. A laser dot marks the location of the bolt. Layout can be checked with independent measurements to the marks.

The choice of field software depends on the person and task involved. PC crews use Trimble Access software for all the surveying work and control. Layout and inspection for site grading is done using Trimble SCS900 Site Controller Software, and engineers and tradesmen use Trimble Field Link software and total stations for layout inside the shaft. Engineers and tradesmen use visual layout techniques, in which the robotic total station automatically places a laser dot at the precise location of a fixture or attachment point.

Keeping and using an accurate model is an essential part of project efficiency and quality control. Any design changes can be double-checked against existing conditions and other design elements before going to the field or fabricator. Extensive checking means that errors and costly rework are avoided, while cloud-based file sharing ensures everyone is using the same correct and up-to-date plans. Everything in the pump station—from concrete structures down to ductwork, conduits and individual anchor bolts—goes through the modeling and review processes.

“If it’s not in the model, then it’s not going to be laid out in the field,” adds Torres.

An image shows the lower levels of the pumping station model. The pipe opening on the lower level is 13 feet (4 meters) in diameter.

Adopting New Technologies

According to Torres, the ability to move information efficiently among the different software and tasks attracted PC to the concepts of modeling, BIM and integrated field operations. But the company’s effort to integrate BIM with field work encountered some challenges.

“In all honesty, it was tough at times,” explains Ron Ellison, PC chief field engineer. “We have this 3D model; how do we get this to the field? We had a lot of qualified people who were willing to jump in and learn to use BIM—we were all teaching each other. I think we’re still learning today.”

New generations of workers are readily adopting the new approaches. According to Ellison, even seasoned workers recognize the value of the 3D models, which enable them to visualize the project components they’re working on and see the relationships to other, yet-to-be-constructed aspects.

PC crews combine measurement and modeling throughout the project. Prior to concrete pours, they can verify that forms and rebar are positioned correctly. Post-pour, as-built measurements enable the model to be updated as necessary. Installers and construction workers use the models to install MEP and other components.

“They don’t need to look at 2D plans and figure out elevations in 2D, which don’t always make sense to humans,” says Torres, adding that misinterpretation of 2D plans is a common source of error. “But with the 3D stuff, it’s just amazing.”

Ellison, who focuses more on machine control, develops site information and constructible models from design documents and sends them to construction surveyors and machines in the field for layout, excavation and grading. The approach produces significant cost savings.

“We’re seeing 30 percent savings, maybe more, from what I call the ‘old school 2D way’ to the ‘modern way,’” notes Ellison. “There’s more work in the office, but savings in the field more than make up for it. Having a model means it’s set up, checked and ready to go.”

Preventing Problems

The work at Blue Plains to date has gone well. “We modeled all the concrete inside the structure; all the anchor bolts and steel pipe supports as well,” says Torres.

The ability to measure and plan in detail delivered major benefits. One example is the installation of a large header pipe that will carry and deliver water from the tunnel to the pumping equipment. Fabricated in sections, the steel header is 13 feet (4 meters) in diameter and runs the width of the shaft. PC rented a special crane to handle the pipe and its supports.

“We only had the crane for a week, and we had just two days to put everything together,” explains Torres. “We needed to put the pipe on its supports at the correct elevation, so we had to shoot inverts on the pipe supports. We worked with zero tolerance, because the pipe is so big and heavy that had we needed to move it, then it would probably break all the anchor bolts, which would be a disastrous setback. Everything was thoroughly planned, checked and re-checked.” The rigorous measurement and checking enabled installation to move smoothly and according to plan.

The model of the entire project site provides a full overview, including details down to individual fittings and anchor bolts.

“It makes it so much nicer to be able to see something in 3D in the office before it gets to the field,” notes Ellison. “That’s our biggest benefit: to catch and eliminate mistakes in the office before they get to the field.”

Harraka pointed to recent graduates emerging from trade schools and colleges as an enabling force for BIM and virtual construction technologies. “It’s our job to make sure the people who want to choose that career path can get the education and start working in it,” he says. “As we go forward, there are going to be more tech-savvy people coming out of university. This can do nothing but grow.”

Moving from Model to Reality

When Abe Torres joined PC Construction in 2008, he arrived with ideas and experience on ways to improve the company’s performance. PC, a South Burlington, Vt.-based, employee-owned construction firm, provides engineering and construction services along the East Coast. With contracts totaling roughly $500 million annually, PC’s clients include water and wastewater treatment plants and large infrastructure, which are Torres’ area of interest.

Torres, who holds the intriguing job title of “Senior Virtual Construction Engineer,” saw the potential to use a blend of spatial technologies in PC’s design and construction processes.

“In the past, it wasn’t unusual to see a lot of rework,” recalls Torres. “A design that works on paper can produce some expensive surprises on the construction site. We’re trying to use technology and leverage computerized design and BIM in wastewater treatment plants.”

The effort gave rise to a new department at PC focused on virtual construction, which blends 3D design and modeling with field measurement, layout and quality control. This ability of the model to adapt to reality delivered major benefits at Blue Plains, where PC has a design-build contract on the pumping stations.

Although it’s common for engineers to produce 3D models for their designs, the models aren’t static, explains Matt Harraka, a virtual design construction manager for CDM Smith, PC’s joint-venture partner at the Blue Plains site. It’s Harraka’s job to carry the model from design phase into construction and ensure the model is kept up to date as construction progresses.

“If you don’t update the model past the design phase, then there’s no real use for it other than seeing what it was like at the end of design,” notes Harraka. “To use it during the construction phase, you need to keep the model current in relation to what’s actually going to be installed. So as shop drawings and fabrication notes come in, the model needs to reflect what will be installed. If not, then you can’t build accurately.”

About Erik Dahlberg

Erik Dahlberg is a writer specializing in the geomatics, civil engineering and construction industries; email: [email protected].