Optimizing Time with VDC:Steel

Project teams are beginning to integrate services inhouse, including steel fabrication, to optimize overall cost and shorten timelines. In the past, the steel fabricator hired a detailing firm, who then created its own model and set of drawings.

In the new approach, the detailing is scheduled up-front instead of in the middle of the project—typically about 60 percent of the way through the design phase. This article details some key considerations to optimize all the benefits.

Workflow and Details

Experienced project teams are evolving toward a workflow where the engineer is only doing engineering, so timing for project planning and execution is reduced—all the team needs to do is provide the general arrangement of framing, which can be done with an analytical model as well as a note sheet sharing the loading requirements, code requirements, special inspections required for that project, etc.

The goal is to cut out some of the design drawings and move directly from concepts to fabrication. The engineer can stamp those plan drawings for permits and move forward into fabrication and erection. The team provides a schematic design with intent, flushes it out at the fabrication level, and then verifies that it’s correct and satisfies their requirements.

Knowing the details chosen for connections gives the engineer and design team a head start in planning their design. Through the process of virtual design construction (VDC), the connection engineering is performed with the engineer of record at the same time, so the review process is cut down by at least 50 percent, because they’ve already been coordinating. By making the service fit into the design timeline, there isn’t duplication of the work, including level of detail.

Providing clear direction to the construction team and consistent file formats for fabricators is critical to project success.

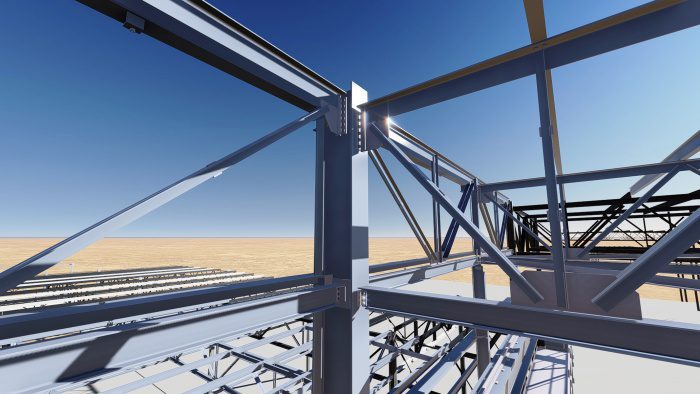

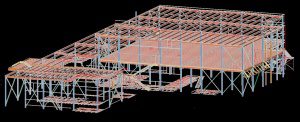

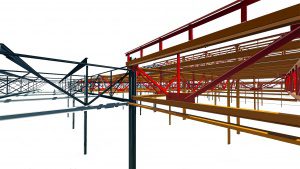

Construction and A&E models typically are a level 300, whereas a fabrication model/drawings would be a 400 level. In a typical 300 model, there’s a column in position in the correct location, orientation and size are correct, and beam framing is there, but there’s no connection. It may or may not have a base plate—it’s just passing on the design intent. Whereas level 400 is fabrication level—base plates, connections, cap plates, clips and angles for beams are all there.

The duplication of work often is due to software incompatibility, and it usually occurs when the engineering firm tries to take it to 300 or beyond. The detailer is going to take it from wherever it is to 400 anyway.

Challenges and Solutions

Optimizing this workflow to realize benefits has challenges. In one scenario, an A/E firm can handle the contract management up front and bid the packages out independently. VDC:Steel services is an innovative application of virtual design technology that seamlessly integrates steel design and fabrication to deliver exceptional quality. Some owners see the benefit of VDC:Steel, but they don’t want to get involved in the contracting process, project oversight and management to deliver success.

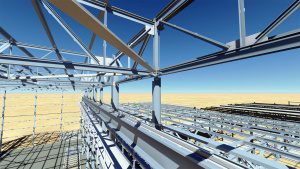

VDC:Steel models save weeks on construction schedules and can be used for clash detection and coordination across trades, ensuring a cleaner, better-delivered finished product

Different contract types allocate risk in various configurations, but VDC:Steel can work for any type of project. It may be a Design-Build project with a general contractor, or it may be a Design-Bid-Build project, where the client selects the general contractor (GC) to bid.

Coordinating and organizing a project in a particular way can sometimes be challenging given the team’s experience. Seasoned professionals may have worked on past projects in a similar fashion for many years and could be less comfortable to change their process.

Typically, it’s the younger professionals, or those with less project experience, who will try out the new delivery system and see how it works. Most experienced project teams have worked with many GCs where teams do the A&E work and provide the details. Whatever the project type, the most significant challenge is winning the collaboration and buy-in from all parties involved.

Clarity also is a challenge; the project’s scope and methodology must be clear. Everyone on the team has to know exactly what they’re doing, why they’re doing it, when it needs to be done, and how it fits together with other trades. If multiple fabricators on the same project are using different types of fabrication equipment, they need to coordinate up front: the design firm should provide computer numerical control files for the fabricators. These files can be plugged directly into automated fabrication equipment to save time and layout.

It’s important to know when the project will be bid and whether or not the finished shop drawings will be used in that effort. When tight numbers are not provided to the bidding firms, the spread of bids may vary as much as 15 percent from high to low. When a firm using VDC capabilities provides the information, the typical spread from high to low is 3 percent.

Applying the new delivery system unveils new advantages. On the positive side, while streamlining the fabrication drawings saves in the construction schedule, it also saves time in coordinating the trades, leading to reduced field fixes and change orders as well as cutting down on the number of RFIs per project. Of course, much of the success revolves around account managers and their relationships with their counterparts at the owner firms working together in a collaborative effort.

A VDC:Steel fabrication-ready model is the first step to a successful project outcome. By including more detail at this early phase, users can eliminate steps later in the process, saving time overall..

A lot can go wrong on a major project if the structural steel portion isn’t done correctly. New technologies allow for smoother project execution while keeping schedule commitments, which appeals to owners and A&E firms alike.

The process brings good information to the table early that wouldn’t be available until later in a conventional project. When a project team is linked in to actual costs, its teams can deliver a Guaranteed Maximum Price (GMP) variance of 5-10 percent for the client to take to the board when pursuing funding. (On most projects, the goal is to get +15-25 percent GMP.) Fabricators also appreciate the single source for drawings, because as long as they build to what’s on the sheet, they aren’t liable if changes are made.

A Case Study

Starwood Capital Group selected SSOE to provide services for a new Apple store. Given a tight timeline, SSOE successfully delivered a detailed engineering package, supporting VDC services, which enabled the Apple store to open on time. To meet the aggressive project schedule, SSOE used VDC: Steel, which offered multiple advantages, from minimized risk to reduced cost and schedule.

Early in the design process, SSOE’s VDC:Steel team worked with mills and warehouses to find structural shapes and sections that were readily available for purchase and fabrication prior to final design. This allowed them to ensure they conformed to the schedule and, in fact, allowed them to change their design based on available material.

This concurrent approach of VDC:Steel, as opposed to a traditional sequential approach, reduced structural steel delivery time by at least three weeks. Using information gathered during materials sourcing, VDC:Steel was able to obtain bids from three separate fabricators within 24 hours, further compressing the schedule by seven days.

SSOE provided a constructability review to identify constraints, risks and opportunities for the project as well as a code review to ensure that the building conformed to all applicable building codes. In addition, SSOE engineered, designed, and detailed the foundation and steel elements inhouse. It also procured the fabricator and raw materials, significantly offloading the client and providing an efficient bridge between design and construction activities.

Today’s savvy owners are looking at new ways to manage and expedite information to make their projects go more smoothly. Of course, buy-in is slow in such an enormous industry as construction, but interest is steadily building. Experienced project teams are committed to changing the industry to this delivery method. It helps the project; it solves problems; and it’s good for the engineer, fabricator, erector and, ultimately, the project outcome.

About Josh Zimmerman

Josh Zimmerman is section manager for VDC:Steel at SSOE Group; e-mail: [email protected].