April 10, 2018 Project of the Week

Project Name: Knight Campus for Accelerating Scientific Impact

Company Name: Thornton Tomasetti

Project Location: Eugene, Oregon United States

Project Information/Details: As University of Oregon students hit the books this spring term, shovels hit the dirt for the first phase of the Knight Campus for Accelerating Scientific Impact, which broke ground March 2 in Eugene, Oregon. Working in collaboration between its Seattle and New York offices, Thornton Tomasetti is providing structural, bridge and façade engineering services to New York-based Ennead Architects, the design architect, and Portland-based Bora, the architect of record, for the project. The facilities are named for Phil Knight, the co-founder of Nike and an UO alumnus, and his wife, Penny, who donated $500 million toward the $1-billion science campus. Phase one of the project consists of a pair of four-story, 75,000-square-foot, L-shaped buildings and a pedestrian bridge featuring a symmetrical arched butterfly design. Image courtesy Bora/Ennead. Designed to fast-track scientific discoveries and innovation, the flexible building program consists of interdisciplinary research laboratories, shared research cores, innovation laboratories and applied graduate teaching. It will have approximately 300 full-time research staff, including top-tier scientists and their support staff as well as 550 undergraduate, graduate and post-doctoral researchers. The two buildings are joined by a lightweight, translucent canopy, underneath which is an elevated terrace. Image courtesy Bora/Ennead. Located in a highly seismic region, the steel and concrete buildings feature a double-glass exterior, steel penthouses, mezzanine floors designed with cross-laminated timber and a 120-foot-long, cable-supported canopy connecting the two facilities. The laboratory floors are designed to house equipment that is especially vibration sensitive. Double-height research floors allow for a floating mezzanine designed with cross-laminated timber, which will hold faculty offices. Image courtesy Bora/Ennead. The buildings’ southern façades consist of glass panels designed to emulate cascading water, while the north elevation features a transparent glass curtain wall system that reveals the buildings’ structure. A bridge designed by Thornton Tomasetti’s special structures group will connect the new facilities to the core campus, passing over the university’s busiest thoroughfare, Franklin Boulevard. A self-supporting spanning element, the bridge features a symmetrical arched butterfly design. It consists of two splayed arches extending from a common support point on each side of the boulevard. The bridge enclosure is supported by cables connected to the floor structure. University president Michael Schill, left, and Patrick Phillips, professor of biology and acting executive director of the new facility, at the groundbreaking ceremony. The campus was designed with input from a building user group made up of scientists, researchers, architects, and construction experts, who explored research facilities across the United States for insight into what makes for a truly interdisciplinary space. The phase one buildings are scheduled to open in 2020. The yet-to-be-designed phase two will add a 65,000-square-foot building, completing the 3-acre scientific research campus.

April 03, 2018 Project of the Week

Project Name: Optimized Low-Wind Turbine

Company Name: Xinjiang Goldwind Science & Technology, Co., Ltd.

Project Location: Dezhou, Shandong, China, Armed Forces Pacific United States

Project Information/Details: Headquartered in Beijing, China, Xinjiang Goldwind Science & Technology Co., Ltd. (Goldwind) is a global wind energy solutions provider responsible for 12 percent of newly installed capacity worldwide. The company achieved its position as the number one international wind turbine manufacturer with a unique business model that spans the whole product lifecycle. Goldwind’s commitment begins with research, development, and manufacturing and continues through investment, sales, and service. This commitment produces wind energy solutions like the recently developed hybrid tower for use in low-wind areas. The innovative design increases the utilization rate for wind energy by 23 percent. Goldwind’s research and development team used Bentley’s structural analysis and detailing applications to develop the tower with a cement base and steel upper section. As a result of the technology integration, the team shortened design time by 35 percent, resulting in a savings of CNY 900,000. Optimized Low-wind Turbine In 2016, Goldwind held 27 percent of China’s market share for newly installed capacity, making the company the largest wind turbine generator manufacturer in the country for the sixth consecutive year. Goldwind continuously upgrades its product line through technical innovation to meet market demand. This demand is fueled by China’s 13th Five Year Plan (FYP), which set a nationwide target of 250 gigawatts of cumulative connected wind capacity by the end of 2020. For this project in Dezhou, Shandong, China, the hybrid steel and concrete tower was designed to make the wind turbine more effective in low-wind areas. The complex implementation process for the CNY 1 million project prompted Goldwind to adopt a BIM strategy. The hybrid tower project involved multiple participants and stakeholders, including managers, designers, contractors, vendors, and subcontractors. Familiarity with the new product development process varied widely among this audience. Using BIM technology allowed the project team to provide transparency enabling collaborative design, multi-discipline model review, and construction simulation. Integrated Modeling and Analysis The project team implemented Bentley’s BIM advancements including ProStructures for steel and concrete design, STAAD.Pro for 3D structural analysis and design, and RAM for load calculation. These interoperable applications allowed the team to assemble 3D design models for each discipline, then use the models to calculate quantities and statistics. Goldwind performed comprehensive collision detection for the multi-discipline models both jointly and separately, and made any necessary design changes. A construction simulation and animation provided insight and direction to the contractors. Bentley’s integrated applications provided the solutions necessary to resolve issues that arose during the project. Goldwind used the interface between ProStructures and STAAD.Pro to shift from modeling to structural analysis and then back again. Model information passed seamlessly between the 3D design applications, allowing the team to analyze and compare different structural designs. Goldwind used RAM and data from STAAD to analyze a wide range of loading conditions. Iteration Strengthens Design Quality Using an iterative design process accelerated the pace of the hybrid tower project. The result was an integrated structural steel and cement model that was closely scrutinized for connectivity, interferences, and constructability. Team members were easily able to understand the status of the current design scheme and participate in making improvements. Goals such as optimizing the size of the wind turbine blade and the use of materials were accomplished as part of the collaboration among disciplines. At every step of the process, Goldwind had assurance that the project’s design specifications would comply with applicable regulations and safety guidelines. Bentley applications included the Chinese design specifications, material libraries, and other information to be considered during design, which helped ensure that the final structural design would fulfill these requirements. The federated BIM approach ultimately allowed the team to deliver a hybrid tower that uses wind energy 23 percent more effectively. Moreover, integrating Bentley’s 3D technology saved the project team more than 400 resource hours during the research and development process, reducing labor time by more than a third and saving the company CNY 900,000. World-leading Product With a presence on six continents, Goldwind is one of a few wind turbine manufacturers in the global market to offer a hybrid tower solution. The company is initially targeting Central, Eastern, and Southern China as well as East Asia. The product not only uses wind energy more effectively but also costs less to construct. Because the tower uses less steel, construction costs are reduced by 15 percent, which accounts for nearly 3 percent of the total installation cost according to industry observers. BIM-driven development of innovative technologies such as the hybrid tower is producing cost-effective solutions on the global market for wind energy. Goldwind’s new products cement the company’s status as a world-leading wind turbine provider and advance wind power as an alternative to fossil fuels. The company will continue to play a leading role in the country’s 13th FYP commitment to source at least 15 percent of its primary energy from non-fossil fuels by Fiscal Year 2020.

March 27, 2018 Project of the Week

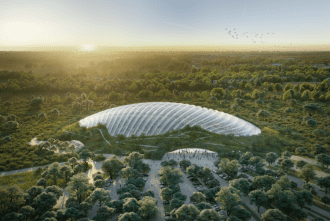

Project Name: Tropicalia

Company Name: Coldefy & Associates

Project Location: Rang-du-Fliers, France, Armed Forces Europe United States

Project Information/Details: On Thursday 22 March, Thomas Coldefy along with Daniel Fasquelle – Deputy of the 4th district, Bruno Cousein – Mayor of Berck-sur Mer and vet Dr. Cédric Guérin – President and founder of the project, unveiled Tropicalia: the world’s biggest tropical greenhouse under one roof. Located in Rang-du-Fliers – in Pas-de-Calais – Tropicalia will offer visitors immediate wonder and a total change of scenery. Offering immersion in a unique environment, it will have a footpath covering over 1 km passing through the environment of dozens of animal, tree and flower species. This architectural feat, respectful of the environment, offers an exceptional oasis for tropical flora and fauna. Tropicalia was designed by Coldefy & Associates as a “harmonious haven” seamlessly integrated into the local environment, with an original innovation : the project is self-sufficient – producing energy through the use of a double dome creating a room in which the air heated through a greenhouse effect. The absence of bearing posts and the presence of a peripheral green wall enhance this cocoon-like atmosphere. The architecture blends in with the scenery: the building is set partially in the ground, thus partially lowering its height and impact. Tropicalia appears to rise like a small hill within the landscape. This is a project financed mainly by private investors. Tropicalia is part of the economic and touristic drive in the Côte d’Opale. A place for discovery and life, the complex offers a number of services around the greenhouse: restaurants, shops, guesthouses, as well as a scientific space exclusively for professionals. Construction on the Tropicalia site should begin in the 1st semester of 2019 for opening in 2021. Over time, it is expected that annually, 500,000 visitors will visit the unique complex designed by Coldefy & Associates.