Effects of Chlorine Dioxide on Plumbing Systems Addressed in New Technical Document

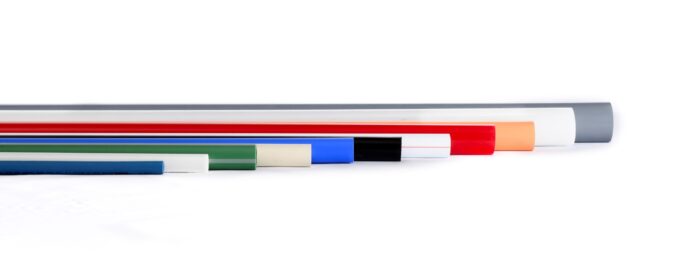

Pressure pipe materials CPVC, PEX, PE-RT, PP-R, and PP-RCT.

Investigation Results by Plastics Pipe Institute Now Available

IRVING, Texas – The Plastics Pipe Institute, Inc. (PPI) has released a new technical document that reports on the association’s findings about the compatibility of plastic piping materials with chlorine dioxide (CIO2) when used in hot- and cold-water plumbing distribution systems.

Prepared by PPI’s Building & Construction Division, PPI TN-67 Chlorine Dioxide and Plastic Hot- And Cold- Water Plumbing Distribution Pipes focuses on the application of chlorine dioxide within buildings and its potential effects on plastic hot- and cold-water plumbing distribution pipe materials.

While chlorine dioxide is rarely used as a secondary (i.e., residual) water disinfectant in public potable water systems, in certain types of large facilities such as hospitals, nursing homes, hotels, apartment buildings, and large office buildings, it is sometimes added to plumbing distribution systems to treat or control outbreaks of harmful bacteria such as Legionella which can occur in these systems. In such facilities, following outbreaks of Legionella or other pathogens in the plumbing distribution system, specialized chlorine dioxide generation devices can be added to inject ClO2 in measured doses directly into the piping system before hot water is delivered throughout the building.

Starting in 2020, a team of experts from PPI member companies began a research project to investigate the potential effects of chlorine dioxide on pressure piping materials CPVC, PEX, PE-RT, PP-R, and PP-RCT.

“Currently, only limited North American industry data is publicly available to predict the impact that chlorine dioxide may have on specific plumbing distribution pipe materials,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division. “PPI TN-67 addresses this topic based on data that has been collected through an extensive analysis of published research combined with the experience and expertise of PPI members.”

Chlorine dioxide is a dissolved gas and is highly volatile and efficient as an oxidizing agent for disinfection. It is used in different concentrations than free chlorine or chloramines and has a different mechanism of attack on the various materials and substances to which it is exposed.

MacNevin continued, “Based on the data that has been analyzed by our association regarding the effects of chlorine dioxide on piping materials in hot- and cold-water plumbing systems, it is apparent that this compound can be very aggressive to certain piping materials. PPI recommends caution when considering its use of as a chemical disinfectant to treat water for the control of Legionella or other pathogens.”

PPI recommends contacting each piping system supplier for guidance on the use of their pipe and fitting material(s) in circumstances where chlorine dioxide has been selected as the disinfection chemical.

Access the full content of PPI TN-67 at https://plasticpipe.org/common/Uploaded%20files/1-PPI/General%20Literature/Technical%20Notes/PPI%20TN-67/PPI%20TN-67.pdf

Additional information and data about piping materials used for hot- and cold-water plumbing systems and other applications are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

About PPI:

The Plastics Pipe Institute, Inc. (PPI) is the major North American trade association representing the plastic pipe industry and is dedicated to promoting plastic as the materials of choice for pipe and conduit applications. PPI is the premier technical, engineering and industry knowledge resource publishing data for use in the development and design of plastic pipe and conduit systems. Additionally, PPI collaborates with industry organizations that set standards for manufacturing practices and installation methods.