Safe Passage Across the Sea: Sensors Prevent Overloaded Vehicles Access to Philippines’ Iconic New Bridge

For the tallest and longest bridge in the Philippines, sensors provide for bridge protection based on accurate measurement of vehicle axle loads. (Kistler Group)

The Philippines, a southeast Asian island state officially comprising 7,641 islands and home to more than 115 million people, is on the rise. Wealth is growing thanks to dynamic economic development in the vibrant Asia-Pacific region; tourism is booming, and increasing numbers of infrastructure projects aim to bridge the gap (literally and figuratively) between the more highly developed north of the country (mainly consisting of Luzon Island and the capital, Manila) and the less-developed south. One such project is the Cebu-Cordova Link Expressway (CCLEX), an elegant bridge with sweeping curves that’s the longest in the Philippines (with a total length of 8.9 kilometers). Construction of CCLEX commenced in 2017 and was completed in 2022. Following the official inauguration on April 27, 2022, the number of vehicles crossing the bridge is expected to rise to 40,000 per day.

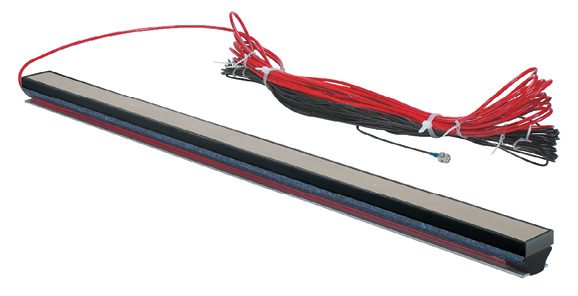

At the heart of the bridge-sensor system are Lineas quartz sensors from Kistler—12 units with a length of 1.75 meters cover a total of six lanes on both sides of the passage over this part of the Pacific Ocean. (Kistler Group)

Complete Traffic Management

Crossing the CCLEX requires payment according to vehicle class; the only toll plaza is located on an artificial island just before the entrance to Mactan Island. To optimize monitoring and maximize safety on the bridge, the Philippine authorities specified a complete traffic-management system that was installed by Indra Sistemas SA, a global technology and consulting company serving the transportation, mobility, aerospace and defense sectors (among others). The traffic-management system consists of incident surveillance, license-plate recognition, speed measurement and more—all functions are fully automated and integrated in one control center.

To monitor vehicle loads and prevent overloaded and potentially harmful vehicles from passing over the bridge, Indra opted for Weigh In Motion (WIM) technology from Kistler. The WIM solution is highly integrated into the overall traffic-management system: it automatically detects and reports overweight vehicles with loads more than 13.5 metric tons per axis (as prescribed by Philippine law).

When trucks are identified as overloaded, they’re directed to the static weighing station at the toll plaza where a confirmation check is performed. The WIM technology is based on Lineas quartz sensors from Kistler combined with inductive loops for vehicle-presence detection and WIM Data Loggers for data processing.

Automatic Vehicle Measurement and Data Processing

Kistler’s solution for CCLEX comprises two WIM installations, each with features that differ due to local conditions. The western installation is located some distance before the bridge, still within Cebu City, because the long and curved ascent ahead of it isn’t appropriate for a WIM installation. Four lanes had to be equipped in this case, requiring eight Lineas sensors: two per lane, each with a length of 1.75 meters. They’re integrated into the road pavement in a staggered layout, together with eight induction loops for vehicle-presence detection. For data processing, all the devices are connected via 40-meter cables to two WIM Data Loggers housed in a nearby roadside cabinet.

At the eastern end of the bridge on Mactan Island, a more-standard installation was possible: four Lineas WIM sensors, four induction loops and one WIM Data Logger cover the two lanes at the CCLEX exit. All necessary electronic components for the WIM solution (FEIG loop cards, Data Loggers, cabling and switches) are supplied by Kistler as prewired components on a DIN rail for easy integration into the roadside cabinets. These also contain connectivity devices and remote-control units to connect the WIM system to the overarching traffic-management system based on SCADA. Vehicle data provided by the WIM solution and automatically transferred to Indra’s traffic-management system include the following: gross vehicle weight, axle load (0 to 50 metric tons), axle distance, number of axles, vehicle speed (3 to 250 km/h) and vehicle length.

The Kistler Lineas sensors for the Weigh In Motion installation at CCLEX (Cebu City side) are checked prior to installation. All components come prewired on a DIN rail for easy installation in roadside cabinets (inset), which are connected to the overall traffic-management system.

Efficient Long-Term Bridge Protection

After overcoming initial challenges and completing calibration, the WIM solution is an integral part of the Indra traffic-management system for CCLEX. The technology ensures that access for overloaded vehicles is restricted, enhancing the bridge’s safety and durability while reducing maintenance efforts.

“Measurement accuracy is within the specifications for all six lanes, and the WIM system is well integrated into our overall solution, including automatic data transmission,” notes Esteban Esteso, project manager for Transport and Defense at Indra.

Bridge Sensors Provide Overall Structural Health Monitoring

WIM systems typically are used to provide modern bridge protection, but they can’t provide any information on the structure’s actual condition. Further technologies frequently associated with condition monitoring and Structural Health Monitoring (SHM) therefore play a significant role. This involves installation of sensors at key positions on the bridge to, for example, record vibrations or changes in the construction material.

Data quality is decisive for reliable condition monitoring. The entire measuring chain from sensor to software must be examined in this respect to ensure that what’s seen on the monitor is as accurate a representation as possible of what’s currently happening on and, indeed, “in” the bridge. For real-time monitoring, particular attention must be paid to the achievement of high-quality signal transmission and data acquisition.

Typical SHM installations include strain sensors and accelerometers to provide complete solutions from sensor to cloud. For instance, K-Beam accelerometers from Kistler were installed in the piers of the Great Belt Bridge in Denmark, a structure which has spanned the Great Belt strait in the Baltic Sea since 1998. These compact sensors continually record changes in natural frequency in real time that could indicate a possible deterioration in the bridge’s condition. Turnkey systems consisting of sensor technology, data-acquisition systems and customized software dashboards also are increasingly employed. Such solutions enable authorities and bridge owners to monitor the condition of these structures continuously and reliably, and they provide support when planning everything from maintenance management to new construction.

About Christoph Klauser

Christoph Klauser is the business development manager at Kistler; email: [email protected].