Self-Cleaning Filters Eliminate Filter Element Replacement and Simplify Maintenance

(Jeffersonville, KY) Spencer Strainer Systems self-cleaning filters remove solid particles from process or wastewater flows of up to 2500 gpm without filter elements or bags. By eliminating the filter element or bag replacement, these unique screens simplify plant maintenance and eliminate another aspect of maintenance downtime. Eliminating bag or element disposal makes these filters the sustainable option, allowing companies to meet facility sustainability goals. Spencer Strainer Systems are a reliable, cost-effective solution for process or wastewater screening applications in a wide range of industries, including food and beverage, paints and coatings, oils, acrylics, toothpaste, pulp & paper products, caulk, biofuels, and more.

Various sized models are available for continuous process flows of up to 2500 gpm. Wedgewire or perforated screens of various openings are available and interchangeable, allowing one strainer to be used for multiple applications.

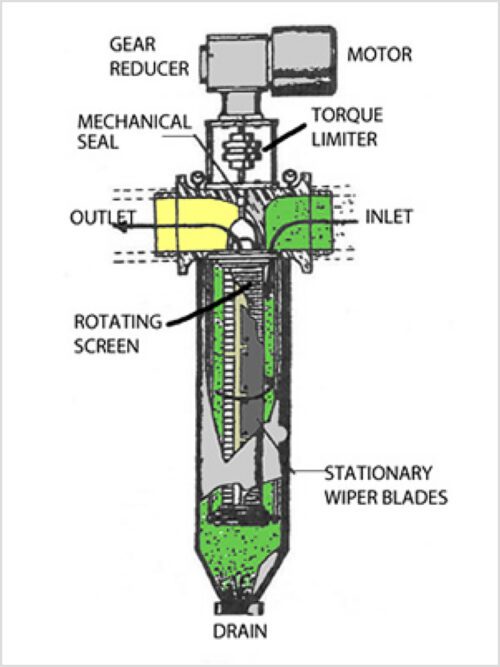

How it works

Product to be filtered enters the strainer through the inlet, with filtration occurring from the outside in. Screened particulate accumulates within the canister and is purged through the bottom drain as needed. Purged particles are piped away for disposal, recycling, or re-use. Spencer Strainers operate continuously as a sealed device, so product stays within the piping and out of the atmosphere, which is especially important for fast curing products like highway striping paint. They are suitable for aseptic operations and work well as pre-filters upstream of membranes, centrifuges, and other fine filter media.

An optional mobile stand allows the units to be moved wherever needed. ASME Code construction is available. Food grade models are also available, as are those for wastewater screening applications.

Monthly test lease and rental programs are available to prove out the approach. All units are manufactured in Jeffersonville, IN with industry leading lead times.

Spencer Strainer has been making their patented strainer for over 25 years. Glenn Spencer built the initial version to filter Colgate toothpaste. It was so successful that other orders soon followed, and the product started to be used in other areas and applications, and around the world. Various industrial, and sanitary models are available to suit product flows to 2500 gpm. The company’s 50,000 square foot facility in Jeffersonville, IN houses design, manufacturing, sales, and corporate support. For additional information visit www.SpencerStrainer.com, call (800) 801-4977, or [email protected]