Better BIM: Laser Scanning Improves Accuracy and Speed in Onsite Data Acquisition

Building information modeling (BIM) first came about in the 1970s, but its methods have been refined considerably since then. Widely used by city planners, architects and civil engineers today, BIM enables stakeholders to better make high-impact decisions by providing timely, relevant information.

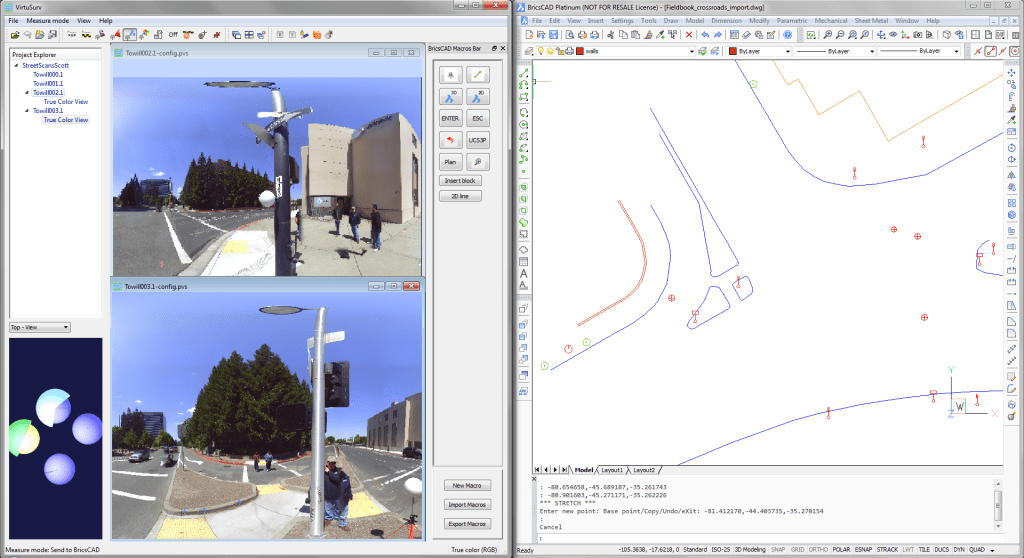

3D drawings can be created with line-fitting and building-specific tools found in the PointSense Building software.

Laser-scanning solutions have shaped the way teams work together, making it easier for them to communicate, collaborate and solve problems that may crop up in the course of a project. Overall, such BIM solutions have resulted in high-quality projects and enabled teams to complete them in a shorter time and at a lower cost.

BIM specialists can use laser-scanning solutions for site documentation, ranging from a facility’s structural design phase to its post-construction architectural phase. Laser-scanning technology captures existing conditions in 3D within minutes, at the touch of a button. With such data, users can create 2D drawings, conduct inspections, create 3D building models and generate site plans registered to global positioning coordinates. Practitioners are increasingly using laser scanners over traditional tools such as total stations, because laser scanners provide them with more detail and data points, which have proven useful when generating final deliverables of a project.

With laser-scanning technology, architects can use real-time 3D data on their computers with less effort, conjuring designs, manipulating drawings or adding elevations—all without compromising on measurement accuracies.

BIM Applications of Laser-Scanning Technology

2D Drawings

Many of today’s building and infrastructure projects lack as-built documentation of existing facilities, and 2D plans or existing drawings rarely are available for old buildings—a major challenge for planning and redesign. In addition, a conventional total station is inadequate for capturing physical structures efficiently, because it can only capture a few points at a time. Not only is the method time- and labor-intensive, the data obtained would be incompatible with point-cloud processing software, limiting their usefulness.

3D documentation solutions such as the FARO Focus3D X Series and FARO Scanner Freestyle3D can address the digitization needs of BIM practitioners. Both devices quickly and reliably document objects, structures or entire rooms with high precision, and their portability makes it easy for scans to be conducted anytime, anywhere. Post-processing of the point-cloud data obtained by the devices then can be performed with FARO’s selection of software (e.g., VirtuSurv, PointSense and SCENE), further simplifying and streamlining the process for users.

Conventional Surveying vs. Laser Scanning

|

Conventional Surveying Equipment |

FARO Laser Scanner Focus 3D X Series |

|

|

Type of Data Collected |

Points and string data only |

Anything within line of sight and visible to the human eye: position, points and photos. |

|

Scanning Speed |

50-150 points per hour |

Up to 976,000 points per second |

|

Scan Resolution |

Average 1 point per square meter |

More than 2 million points per square meter |

|

Type of Data Output |

Usually a 2D or 3D CAD Plan |

Detailed 2D/3D CAD; 3D model; point-cloud data in DTM, DEM, DSM, Contour formats. |

|

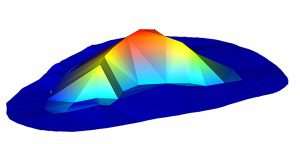

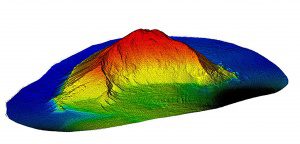

Sample Scan Result |

|

|

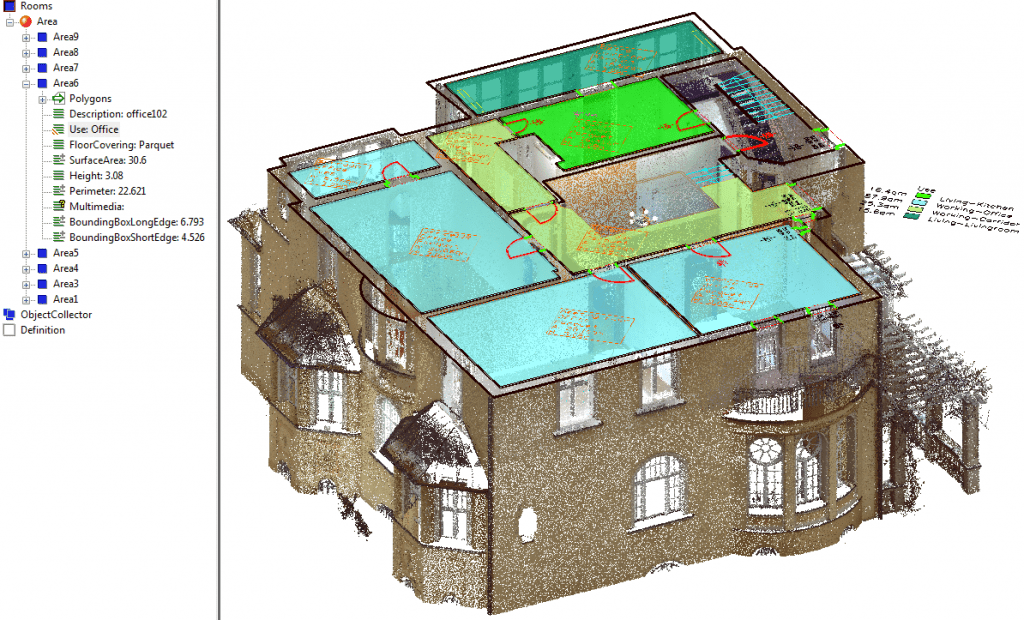

A 3D building model (bottom) was created with PointSense Revit through post-processing of point-cloud data (top) obtained via laser scanning.

Structural Inspection

Structural damage to buildings can cause substantial economic losses to property owners, and can also reduce a property’s current and future value. Structural inspections enable owners to take preventative measures or make necessary rectifications.

With traditional surveying tools, data capture for structural inspection is slow and inflexible. Moreover, the extent of damage can’t be monitored with certainty, and the evidence is documented only in 2D images. Laser scanning can provide the information required for an effective assessment.

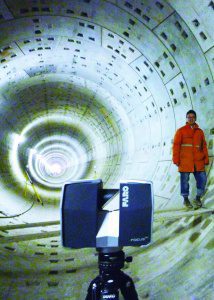

Laser-scanning technology can be applied in railway construction and monitoring of tunnel deformation.

For example, an analysis of concrete floors for slab flatness will indicate if any area needs to be adjusted, after which BIM specialists can determine the volume of material needed for that job, resulting in less waste and better cost management.

In addition, laser-scanning technology can be used to verify that building components have been installed according to the original design, which is helpful for cost management, insurance claims or legal disputes. Laser scanning can perform as-built documentation with millimeter accuracy, capturing details such as pipes, HVAC systems, structural steel, floors and rebar in concrete slabs throughout a building. If any discrepancies are observed when compared against a design, property owners can make alterations or rectifications as necessary.

3D BIM

Contractors of building and infrastructure projects often don’t record current construction or maintenance documents of the existing facility. Acquiring digital survey data of a large space via conventional methods would be time-consuming and laborious, and data incompatibility can make it difficult for the team to import such information into any of the popular CAD programs available in the market.

Similar to how 2D drawings can be generated from laser scans, producing 3D BIM is easy with laser-scanning documentation solutions. The FARO VirtuSurv software, as an example, allows users to import and export scan data for use on various platforms. The FARO PointSense Building software, an AutoCAD plug-in, then processes the 3D scan data with a range of available tools, allowing users to manipulate information for specific project deliverables.

Success Stories from Asia

In 2014, the Third Building Construction Company of China Construction Eighth Engineering Division (CSCEC83) embarked on a new project to construct the Jiangsu Grand Theatre and complete the handover by June 2016. Given the project’s large scope (a total net land area of 196,633 square miles and a total construction area of 271,386 square miles), the team was pressed for time. The theatre’s unique design added to the complexity of the project in terms of quality control.

A 3D building model was created with PointSense Revit through post-processing of point-cloud data obtained via laser scanning.

Previously, the team was using an Electronic Total Station (ETS) to test the accuracy of abnormally shaped structures by comparing structural key points. Due to the limited numbers of data points collected, the test results were inherently incomplete and unreliable. Coupled with the complex double-curved surfaces on the water-droplet structures, it was practically impossible for the team to achieve proper, accurate results using the ETS.

“The shape of water droplets is distinctive and poses a great challenge to the quality of our construction as well as to the amount of control we have over this project,” explains Zhang Bowei, BIM supervisor of the Project Department at CSCEC83.

To overcome this challenge, the team decided to use the FARO Focus3D X 330, which could scan entire curved surfaces, resolving the quality-control issue. A job that used to take an entire week or more was instead accomplished in just two days.

Another success story is from the Beijing Urban Construction Exploration & Surveying Design Research Institute (Beijing Urban), which undertakes projects involving railway construction and detection (or monitoring) of tunnel deformation, providing independent appraisals that contribute to the safety of civil engineering projects.

Using the FARO Focus3D, the team now can generate better reports for its customers, including tunnel cross-sections, histograms and 3D model outputs.

“Using the total stations, the team would need up to eight hours just to collect data,” notes Zhang Yun Ming, development engineer at Beijing Urban. “That’s not including the time taken for processing and analyzing the information. With the Focus3D, we only need around three to four hours.”

As a third example, Hibiya Engineering Ltd. provides engineering services (e.g., air conditioning, water supply, drainage and sanitation, electricity, etc.) as well as information and communication technology services to building owners. At the end of 2011, Hibiya Engineering invested in a FARO Laser Scanner Focus3D to facilitate the measurement of existing facilities. Using the new device, it takes the team only an hour to measure existing facilities that are due for renovation, with a measurement process that is significantly simpler than previous methods, requiring only a handful of workers to obtain high-quality measurements safely and within a short time period.

Moreover, the device also reduced the need for any rework, saving Hibiya Engineering precious time on projects. In the past, when the team relied on hand tools and paper records, it was common for engineers to revisit a site to repeat measurements because figures did not match up. However, with a laser scanner, engineers can “revisit” the point-cloud data on a computer as often as required, without having to physically return to the equipment room.

A 3D building model was created with PointSense Revit through post-processing of point-cloud data obtained via laser scanning.

“For renovation projects, subcontractors like us can now bid and win them as the contractor,” notes Mitsunori Taya, technology division manager of the Planning Engineering Department at Hibiya Engineering. “We have set ourselves apart from the competition with [laser scanning] and the BIM design process.”

Modern laser-scanning technology is yet another piece of the equation that allows BIM to replace traditional drawings and other legacy techniques, enabling teams to virtually design and build a 3D model of any given facility on a computer in completely digital form.

About Chew Beow Kwan

Chew Beow Kwan is product marketing associate manager, Asia Pacific, at FARO Technologies; e-mail: [email protected].