January 23, 2024 Project of the Week

Project Name: 194th Avenue Slope Protection Project

Company Name: Presto Geosystems

Project Location: Calgary, Alberta

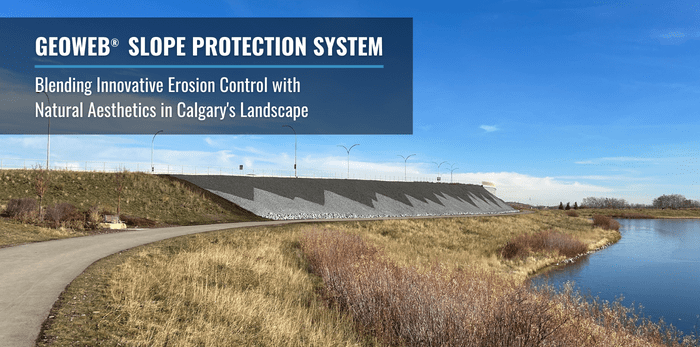

Project Information/Details: Project Objective and Background The 194th Avenue slope protection project in Calgary focused on stabilizing a steep slope adjacent to a Geosynthetic Reinforced Soil (GRS) structure. The slope angles ranged from 3:1 to 1:1 with slope lengths up to 15 meters. The 1:1 slope’s south-facing orientation and lack of irrigation made it especially susceptible to erosion, compromising the existing vegetative cover’s stability. In response to the need for a durable, low-maintenance solution that would seamlessly blend with the natural environment, Layfield Canada recommended the GEOWEB® Slope Stabilization System. This choice was driven by its exceptional erosion control properties, addressing the slope’s specific protection requirements while ensuring long-term stability and visual harmony with the surroundings. Challenges in Slope Stabilization The primary challenge of the 194th Ave project stemmed from rapid erosion that exceeded the protective capabilities of the original geogrid and Erosion Control Blanket (ECB) design. The critical task was to devise a system capable of effectively stabilizing the slope. This solution needed to meet both functional stability and aesthetic considerations, moving beyond the initial strategy that relied heavily on vegetative cover. Optimizing Slope Stabilization and Aesthetics with the GEOWEB Geocells The GEOWEB Slope Stabilization System was chosen for its strength and versatility. Notably, the infill design was intentionally patterned to resemble mountainous terrain, ensuring both functional erosion prevention and a visually striking appearance that blends harmoniously with the environment. Installation The installation of the GEOWEB Slope Stabilization System involved several key components, including: GEOWEB GW30V4 with 29 cells per panel TP225 polyester tendon ATRA® tendon Clips ATRA® Keys Falcon Earth Anchors strategically positioned at the crest of the slope 6 oz. non-woven geotextile separation layer During installation, TP225 tendons were connected to f modified Falcon Earth Anchors strategically placed at the crest of the slope to ensure the secure anchoring of the GEOWEB system. A total of 450 anchors were installed, and each underwent thorough QA/QC testing to verify they met the desired 10.5kN pull-out strength. In conjunction with anchor placement, a small layer of topsoil was underlaid with 60mm clear stone at the crest of the slope. This dual approach not only enhanced the system’s stability but also contributed to effective erosion prevention. The installation also included the use of TP225 tendons, ATRA® Tendon Clips, and ATRA® Keys, which played a critical role in connecting the GEOWEB panels and reinforcing the overall stability of the system. After the GEOWEB system was secured, the stone fill was meticulously arranged within the GEOWEB 4-inch-deep cells to craft an aesthetically pleasing mountainous landscape on the slope. This process seamlessly combined functionality with landscape aesthetics. Two different types of stone, limestone and rundle stone, were skillfully used to create the distinctive appearance of the finished project. GEOWEB Geocell System Benefits The installation of the GEOWEB System offered several benefits: Significantly reduced maintenance efforts for slope stabilization. Protection of the longevity of the GRS structure from further erosion. Enhancement of the slope’s facade, seamlessly blending with the natural landscape. The 194th Ave slope stabilization project successfully addressed environmental challenges with an innovative and effective engineering solution, demonstrating a commitment to delivering functional and visually appealing results.

January 16, 2024 Project of the Week

Project Name: Woodside Energy’s Trion Floating Production Unit

Company Name: Wood

Project Location: Gulf of Mexico, Mexico

Project Information/Details: Wood, a global leader in consulting and engineering, has secured a contract from HD Hyundai Heavy Industries for detailed engineering of the topsides facilities on Woodside Energy's Trion Floating Production Unit (FPU) in Mexican waters of the Gulf of Mexico. When complete, Trion will have a production capacity of 100,000 barrels per day and connect to a 950,000 barrel capacity floating storage and offloading vessel. This greenfield development will represent the first deepwater development in Mexico at a water depth of 2,500 meters. HD Hyundai Heavy Industries is the engineering, procurement and construction (EPC) provider for the FPU and Wood's latest award follows the delivery of the Trion pre-FEED and FEED design. John Day, President of Oil, Gas and Power at Wood commented, "We are pleased to have been selected as the topsides engineering provider for Trion by Woodside Energy and the project's EPC Contractor, HD Hyundai Heavy Industries. Wood's innovative design process on the pre-FEED and FEED work positioned us well for the detailed engineering scope on Trion. "Applying a practical approach to decarbonisation in the design process has been an important part of this project, whilst ensuring safety and quality. Our team has a proven history with Woodside, having worked together for two decades, and our experience designing and delivering solutions for Trion will improve productivity, reduce emissions and maximize the return on investment for our client." SeonMook Lim, Engineering Vice President of Offshore Engineering Division as HD Hyundai Heavy Industries commented, "We are very pleased to reunite with Wood through the Trion FPU Project for the first time since we worked on the East Area Natural Gas Liquids Offshore Project in West Africa in 2005. We are greatly enthusiastic about creating another EPC success story that will leave a lasting mark in the history of offshore oil and gas development. We look forward to continuing our relationship with Woodside as we embark on Trion FPU project." Wood's teams in Houston (US) and Bogota (Colombia) will deliver the detailed topsides design work for the FPU project over the next three years. In the last decade, Wood has designed more than 50% of topside facilities in the Gulf of Mexico today.

January 09, 2024 Project of the Week

Project Name: Sheybarah Island Resort Installation

Company Name: Mammoet

Project Location: Sheybarah Island, Saudi Arabia

Project Information/Details: Mammoet, the global leader in engineered heavy lifting and transport, is delighted to announce the successful completion of its scope for the Sheybarah Island resort, in collaboration with Red Sea Global. The project, a crucial element of the world's most ambitious regenerative tourism endeavor— The Red Sea destination - has achieved a significant milestone with the installation of the last villa on Sheybarah Island. This marks the conclusion of a transformative journey that commenced with the signing of the contract in May 2022. Mammoet’s scope involved the transportation and installation of 73 prefabricated villa orbs from Sharjah, United Arab Emirates, to Sheybarah Island in the Saudi Red Sea. The resort, featuring a hyper-luxury hotel designed by Killa Design, with uniquely shaped overwater and beach villas, front-of-house, and F&B buildings, now stands as a testament to Mammoet's commitment to precision and excellence in engineered heavy lifting. From the initial contract award, Mammoet demonstrated its expertise by overseeing the complete factory-to-foundation process and ensuring a seamless integration of these architectural marvels into the pristine landscape of Sheybarah Island—a habitat rich in mangroves, white sand dunes, and vibrant coral reefs. The installation of the last villa is a momentous occasion that reflects Mammoet’s dedication to executing complex projects. The use of tailor-made solutions, including the deployment of a 650t capacity Demag CC3800 crawler crane on Mammoet’s modified barge, ALE 250, underscores Mammoet’s commitment to minimizing environmental impact. The shallow draft of the barge, coupled with a retrofitted 300t spud jacking system from Mammoet's partner Combifloat, ensured minimal disruption to the delicate marine environment during the installation process. Precision engineering, hyper-accurate GPS systems, and locally controlled jacking mechanisms contributed to the flawless placement of the overwater villas onto their foundations. The Red Sea, a key giga project announced as part of Saudi Arabia's Vision 2030, spans 28,000 square kilometers and is expected to provide a significant boost to the country's GDP, supporting economic diversification and generating employment opportunities. The completion of the installation of all orbs on Sheybarah Island Resort marks a pivotal moment in the realization of this visionary project. Jack van den Brink, Managing Director for Mammoet Middle East and Africa, expressed his excitement, stating, "We are proud to have played a pivotal role in bringing RSG's vision to life. We remain committed to delivering excellence in every project, in this case contributing to the creation of the world's most spectacular and sustainable hotels."