Vortex Introduces Total UV CIPP System

Comprehensive UV CIPP Curing Technology, Liner, and Equipment Solutions Expand Installers’ CIPP Installation Capabilities

(HOUSTON, TX) – The Vortex Companies, a leading provider of advanced trenchless water and sewer technologies and infrastructure renewal services, introduced today its new, comprehensive UV CIPP Systems solutions portfolio. Vortex’s UV CIPP curing equipment systems, liners, and custom truck builds backed by expert training and support, enable the company to be a valuable partner in the rehabilitation of aging infrastructure.

“UV CIPP is a powerful addition to a contractor’s CIPP toolbox,” said Mike Vellano, CEO of the Vortex Companies. “With demand growing for UV CIPP as an alternative solution, we are a single source for everything contractors need to add UV CIPP to their trenchless rehabilitation solution set.”

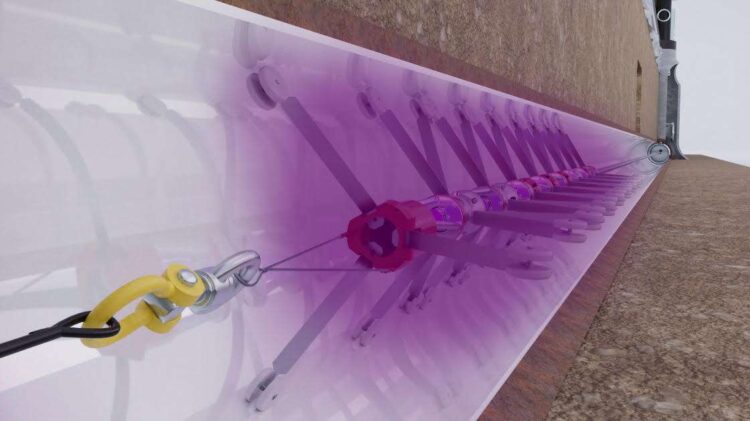

Commonly used in Europe, UV CIPP provides contractors, engineers, and asset owners with a proven approach to expand their existing use of CIPP technology in a way that allows additional installation flexibility and environmental advantages. Vortex offers the most advanced UV curing equipment options available through its strategic partnership with IMS Robotics. Accommodating pipe diameters 6” to 80”, Vortex’s IMS UV Curing Systems deploy an ultra-violet ‘light chain’ and infrared sensors to capture data every 12” to ensure a complete cure and improve installation efficiencies.

“We are set up to sell curing technology to customers looking to expand or upgrade their current fleet,” said Matt Timberlake, SVP Shared Services at Vortex. “Our Greenville, South Carolina facility is also equipped to custom build UV CIPP trucks for both new and existing customers.”

Vortex’s new EnviroCure UV® Liner, developed in partnership with Applied Felts, is pre-impregnated with resin and constructed using a corrosion-resistant, styrene barrier sleeve, non-wicking fiberglass to enhance physical strength while delivering a thinner pipe wall design. Its unique construction enables reinstatements to be performed quickly and correctly the first time with reliable dimpling that clearly identifies junctions between laterals and the main line, saving several minutes per lateral to return assets to service faster. Additionally, the liner is cold and hot weather-friendly, ideal for environmentally-sensitive locations, manufactured in the USA and readily available – as quickly as two weeks – to speed project completion.

To ensure new customer success, Vortex also offers an immersive training program that includes classroom-based operations instruction equipment training and live field training, backed by ongoing remote technical support.

“This advanced approach to UV CIPP system support significantly increases a contractor’s early success and long-term growth in this expanding segment of the CIPP installation market,” added Timberlake.

To learn more about Vortex’s complete, end-to-end UV CIPP systems solution approach, visit vortexcompanies.com/uv-cipp-lining-systems.