Code Update: Reapproval of ASTM C1776 Sets the Bar for Manufacture of Precast Concrete Modular Retaining Wall Units

In May 2022, the American Society for Testing and Materials (ASTM) published the reapproved ASTM C1776: “Standard Specification for Wet-Cast Precast Modular Retaining Wall Units.”

ASTM C1776 specification sets the minimum criteria for materials, inspection, testing and certification of wet-cast precast concrete modular retaining wall blocks.

The specification is organized into 17 sections:

• Scope

• Reference Documents

• Terminology

• Ordering Information

• Materials and Manufacturer

• Physical Properties

• Dimensions, Mass and Permissible Variations

• Workmanship, Finish and Appearance

• Sampling

• Frequency of Tests

• Specimen Preparation

• Test Methods

• Inspection

• Rejection and Rehearing

• Certification

• Product Marking

• Keywords

Many National Precast Concrete Association (NPCA) Certified Precast Production facilities produce modular retaining wall blocks to this strict standard specification. These blocks often are called “precast modular retaining wall units” and are not to be confused with the small retaining wall blocks more commonly used for residential use and shorter-height commercial walls.

In the Code

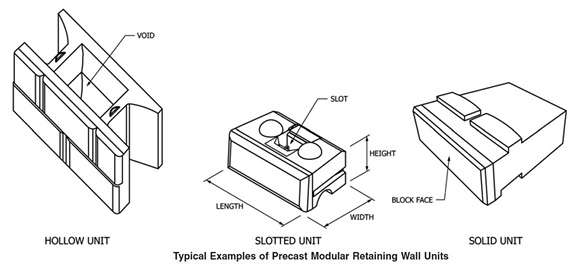

Retaining walls up to 50-plus feet tall using ASTM C1776-compliant modular retaining wall units are not uncommon. Depending on design requirements for the wall, the wet-cast precast concrete blocks covered under this standard specification are sometimes as large as 3 feet tall by 8 feet wide by 7 feet (plus or minus) in depth. (See accompanying figure for examples.)

Customers can be assured they’re getting quality precast concrete retaining wall blocks due to the rigorous testing required by the ASTM C1776 standard. For example, specific, required tests include measured dimensions of blocks within a tightly specified tolerance, compressive strength, air content and freeze-thaw durability. Test frequency is specified within the standard specification and also is in alignment with the NPCA’s Quality Control Manual for Precast Concrete Plants requirements.

Drilling down a bit deeper into the specification’s quality requirements, sometimes overlooked areas include workmanship, finish and appearance. This section requires that the “precast modular retaining wall units shall be sound and free of cracks or other defects” and that when delivered to the project site, they shall also “not exhibit chips or cracks in the exposed face or faces of the units.” When examining appearance, pay special attention to the final color and texture the specification mentions. The standard specification mentions that the specifier/owner is to select the color and texture based on what’s available from local manufacturers. Keep this in mind when specifying precast concrete modular block retaining walls.

Code Necessary?

Leaving this ASTM standard out of project specifications with a retaining wall can result in a contractor installing a waste-type concrete block that has no color options, no quality-control testing and no exposed face finishes. In addition, variations in the waste block unit dimensions that exceed the tolerances allowed in ASTM C1776 can result in cracking and other performance problems in installed walls. Thus, waste-type concrete blocks are less aesthetically pleasing when compared to ASTM C1776 modular precast concrete retaining wall blocks that come with patterned exposed faces, tight tolerances and color, if desired.

As an owner or specifying engineer, requiring compliance to ASTM C1776 for retaining wall blocks on a project will ensure the owner is getting a quality product that will last for decades to come. Some notable benefits of precast concrete retaining wall modular blocks are quality construction within a controlled environment, quick installation, financial savings and being a durable, resilient product.

For more information on NPCA and how it serves the precast concrete industry, contact NPCA Senior Director of Membership and Regulatory Services Chris Frederick at [email protected].

About Daryl Burns

Daryl Burns, P.E., is a product engineer at Garden State Precast and a former NPCA Director of Codes and Standards.