Municipal Sewer Cleaning: Train for Gain

Best-practice techniques and equipment options help municipalities and contractors clean sewer, storm and sanitary lines more efficiently.

For municipalities and contractors with heavy workloads cleaning sewer, storm and sanitary lines, the fastest route to getting the work done on-time and on-budget often is learning best-practice techniques and equipment options, demonstrating them onsite, and then resolving specific problem areas in the field with expert guidance.

“Traditionally, sewer-cleaning techniques are passed down on the job from person to person, but seldom systematically taught,” says Marty Tew, a water resources construction field supervisor for the Fayetteville, N.C., Public Works Commission (PWC). “In our case, we always instructed that you go up toward the manhole and then start cleaning as you return. That is a misconception in the industry—one we lived with until we got expert training.”

Fayetteville’s PWC maintains more than 1,300 miles of sewer mains, 79 miles of forced sewer mains and 85 lift stations. As a regional utility provider, PWC also maintains and operates several sanitary sewer systems in the area.

“In years past, we had to repeatedly clean a lot of sewer line because we were not effectively getting the job done,” adds Tew. “This was due to insufficient training and not using the most-effective cleaning nozzles and equipment for the job.”

According to Tew, the municipality’s management and technicians’ eyes were first opened to the effectiveness of best-practice techniques and equipment during a hands-on sewer-cleaning demonstration following onsite training.

“When we saw our trainer’s hands-on demo in the field, we could not believe what a difference using the best tools and techniques made,” he notes. “It was ‘proof in the pudding’ for me and our operators.”

Optimizing with Training

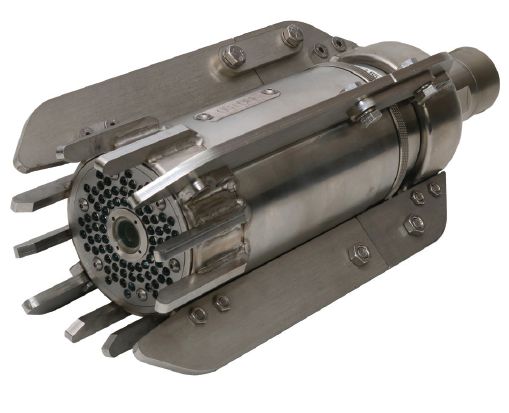

Tew, his managers and operators received best-practice sewer-cleaning training from KEG Technologies, a manufacturer of sewer and storm-line products including Tier 1 to Tier 3 nozzles, chain cutters, floor cleaners and camera nozzle systems. The Spartanburg, S.C.-based company is a member of the National Association of Sewer Service Companies (NASSCO), and its Tier 3 nozzles, such as the Torpedo and OMG, provide up to 98-percent efficiency.

Typically, training begins with a quick overview of water-system basics to “fill in some critical gaps in knowledge,” according to Dan Story, an experienced trainer and operations manager at KEG. This usually covers the essentials of the water pump, hose reel and hose, water pressure gauge, flow vs. pressure, and nozzle.

Expert training, onsite demonstration and in-the-field resolution of the toughest challenges help operators and contractors become significantly more productive.

Although all these factors are vital to sewer cleaning, to ensure a job done well and on budget, the key is selecting and applying the correct nozzle for the job, according to Story. “Nozzles are designed to ‘jet’ material back to the evacuation point and are ‘front line soldiers’ when cleaning any pipe,” he says.

There are tiers of nozzles, which NASSCO rates for water efficiency from Tier 1 (about 30-percent efficient) to Tier 2 (50- to 60-percent efficient) to Tier 3 (75- to 98-percent efficient). Story explains that in many cases, using a high-efficiency Tier 3 nozzle will provide significantly more cleaning force, at a greater distance, with less water. This enables crews to get more line cleaned before having to leave the jobsite to refill the sewer truck with water.

However, even within the Tier 3 category, there are significant differences in levels of efficiency. Opting for a lower-end Tier 3 nozzle with 75-percent efficiency could still lead to additional trips to refill. Additionally, such units may not remove restrictive sewer buildup or blockage in a timely manner.

The internal workings of the nozzle, including the way the water gets turned, redirect the energy of the high-pressure water entering the nozzle as efficiently as possible to create more thrust and power using less water.

According to Story, a Tier 1, 30-degree drilled nozzle running 72 gallons a minute at 2,200 PSI will only exert 13 pounds of force to move debris 9 feet away from the nozzle. In contrast, a very-high-efficiency Tier 3 nozzle running 60 gallons a minute at 2,000 PSI will impact debris nine feet away with 98 pounds of force.

“If your objective is to remove debris out of the sewer line, which one’s going to do it better, 98 pounds of force or 13 pounds of force?” asks Story. “Using high-efficiency Tier 3 nozzles is key to getting more done in less time.”

What sets the most-efficient Tier 3 nozzles apart from others in the category is fluid mechanics engineering on a par with the aerodynamics of race cars or jet fighters.

In the case of KEG’s Tier 3 nozzles, the high-performance fluid mechanics design leaves little room for power losses and excessive turbulence. After exiting the jetter hose, water travels into the body of the nozzle before moving through smooth, curved channels. This design enables the water to maintain its power and speed before entering the nozzle’s replaceable titanium ceramic inserts. Next, the water is funneled from a short conical shape to a larger, longer cylindrical shape, allowing a tight water pattern to emerge.

The internal workings of the nozzle, including the way the water gets turned, redirect the energy of the high-pressure water entering the nozzle as efficiently as possible. This results in what’s needed for the task: more thrust and power using less water.

The Allen Park, Mich., Water and Sewer Department (within the Department of Public Service) has responsibility for duties such as sanitary sewer/storm sewer inspection, cleaning and repair. To improve the department’s capabilities, KEG trained its new and experienced operators in a one-day, onsite session.

The high-performance fluid mechanics design in KEG’s Tier 3 nozzles leaves little room for power losses and excessive turbulence. Going slow and using less water with the proper nozzle is more effective than rushing and having to make multiple passes.

According to Justin McLaughlin, a Public Service worker involved with inspection and cleaning in the city’s water and sewer department, the training included a hands-on demonstration.

He notes that one highlight was hooking up the department’s hydro excavator sewer cleaner to a 6-foot-long clear pipe and using a hose with various high-efficiency Tier 3 nozzles to visually show the difference such nozzles can make. He credits the training and demonstration with creating a clearer understanding of effective sewer-cleaning technique.

“If you clean too fast, you only remove the surface layer and leave sediment on the bottom,” explains McLaughlin. “However, by cleaning slower, you can cut through the entire layer of debris, chop it up and vacuum it out. The takeaway was that going slow and using less water with the right nozzle is much more effective than rushing and having to make multiple passes.”

McLaughlin points to the difference the training has made in his own effectiveness.

Camera nozzles such as KEG’s KleenSight Camera-Nozzle System can simultaneously clean and record video for viewing, troubleshooting and documenting problem areas and their resolution.

“Cleaning a larger-diameter sewer line our old way would have taken me several passes,” he notes. “After the training, I was able to clean it in one pass, while saving water and a trip to a hydrant to refill the truck’s water tank.”

According to McLaughlin, Allen Park’s Water and Sewer Department now uses high-efficiency Tier 3 nozzles in the field.

“The result has been cleaner sewer lines and more-efficient cleaning,” he adds. “We are not having to repeat clean the same area or clean extra for inspection.”

Resolving Challenging Issues on the Job

When cleaning sewer, storm and sanitary lines, municipalities and contractors will encounter a host of issues, such as tree roots, total blockages and “blown toilets” that will require the use of special techniques and equipment to resolve.

For example, specialized nozzles can reduce certain issues: cutters can help with roots/vegetation; penetrating nozzles with total blockages; and rotational nozzles with soft blockages, according to Story.

In addition, camera nozzles can simultaneously clean and record video for viewing, troubleshooting and documenting problem areas and their resolution.

According to Tew, the benefits of receiving expert training and switching to ultra-efficient Tier 3 nozzles helped Fayetteville’s municipal PWC significantly. “With the training and Tier 3 nozzles, we achieved about a one-year ROI,” he explains. “We attained more-efficient labor and resource use. This included reduced fuel use as well as vehicle and crew downtime.”

While Tew doesn’t insist a Tier 3 nozzle is necessary for every job, he does recommend it as an essential tool for the municipal sewer crew’s toolbox. He points out that the increased efficiency of Fayetteville’s municipal PC work crews, equipped with Tier 3 nozzles and expert training, has made meeting North Carolina state mandates for sewer maintenance easier.

“We are now using less water per pipe segment [with the Tier 3 nozzles], and our employees love it,” says Tew. “We do not have to work as hard but get more done. We are working smarter, not harder.”

As a case in point, he adds, “We are mandated by the state to clean 10 percent of our sewers a year. While we have always met that target, we are actually above the goal now, and our cleaning is far more efficient.”

Tew concludes, “I’d highly recommend that any municipality, rural system or contractor with sewer-cleaning or emergency-blockage crews seek expert training. It will be an ‘eye opener’ for them. More importantly, it will change how they do their jobs for the better.”

About Del Williams

Del Williams is a technical writer based in Torrance, Calif.; email: [email protected].