Code Update: IAPMO 2021 Uniform Codes and Standards

The International Association of Plumbing and Mechanical Officials (IAPMO) continues to protect the public through its ANSI-approved development process where third-party oversight ensures a true consensus document. The Uniform Codes maintain the necessary balance between prescriptive requirements and allowable performance standards; it details exactly how a system needs to go together.

The provisions in the Uniform Codes are specifically written to protect the public and aid jurisdictions throughout the United States. The Uniform Codes are the only codes that contain the latest technology with the appropriate safety requirements.

IAPMO published the 2021 Uniform Plumbing Code (UPC) and the 2021 Uniform Mechanical Code (UMC) in March 2020. The codes were improved with safety provisions for protection from legionellosis, safe installation of alkaline water-treatment devices, and requirements for leak detection, to name a few. For the complete listing of updates and additional information beyond this brief summary, visit the IAPMO website at www.iapmo.org.

Key Changes to the 2021 UPC

New Legionella Provisions

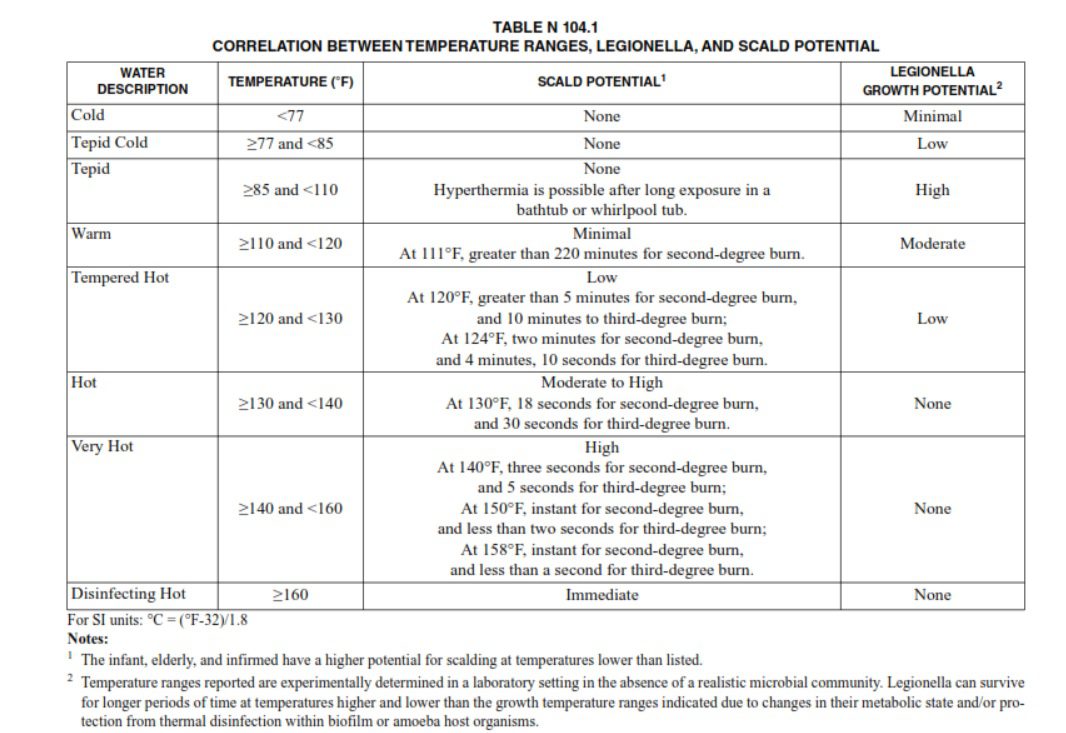

Legionnaires’ disease is a serious issue across the United States that’s affecting many citizens. IAPMO’s effort to address this growing concern led to the formation of Appendix N (Impact of Water Temperature on the Potential for Scalding and Legionella Growth). The UPC Technical Committee saw the need to implement code language to understand the health and safety risks associated with legionella and scald-risk exposure for single-family residential buildings. It’s widely known that the higher the temperature, the lower the risk for legionella growth; but the higher the temperature, the higher the possibility for scalding. To tackle this issue, Appendix N was formed; it’s the first national document to address this important issue.

Below is an example of the table that gives jurisdictions the flexibility to implement a program depending on risk. The appendix also contains specific provisions for disinfection, and it’s written so it can be implemented with legionella risk-management systems such as ASHRAE 188 and ASHRAE Guideline 12, in accordance with the adopting jurisdiction.

Water-Dispenser Requirements

Section 417.6 adds provisions for low-pressure water dispensers, which the codes didn’t address. These dispensers currently are within the scope of ASME A112.18.1. However, dispensers that dispense electrical-heated water and have an integral reservoir of hot water vented to atmosphere generally already are in compliance with ASSE 1023. Products covered by ASSE 1023 include, but are not limited to, under-counter-mounted water-dispensing systems, freestanding plumbed systems, freestanding bottled systems and countertop systems.

Leak-Detection Devices

Water is a global resource that must be cherished and protected, and IAPMO has long published standards that address water-leak-detection products, including IAPMO IGC 115 and IAPMO IGC 349. These standards are used for the listing and certification of products designed to detect water leaks. Jurisdictions nationwide are already looking for the IGC 115 and IGC 349 mark for these products.

Alkaline Water-Treatment Devices

There’s a health trend in the market for drinking alkaline water (with a pH above 7.0). There are many claimed health benefits, including neutralizing stomach acid and increasing oxygen levels in the blood. Although these water-treatment products haven’t had any formal procedures to verify their claims of health benefits, IAPMO standards seek to ensure the products dispense alkaline water for safe consumption. IAPMO IGC 322 provides the output performance requirements for flow rate and oxidation-reduction potential at given pH levels.

The IAPMO Z601 standard provides the performance criteria for any scale-reduction device intended for tank-type and tankless water heaters as well as ion exchangers. It covers material safety, structural integrity and various safety requirements. Products are being installed today in plumbing systems that haven’t been tested for scale-reduction performance or safety. IAPMO Z601 fills that gap, ensuring products being installed will perform as marketed and meet minimum standard requirements for health and safety.

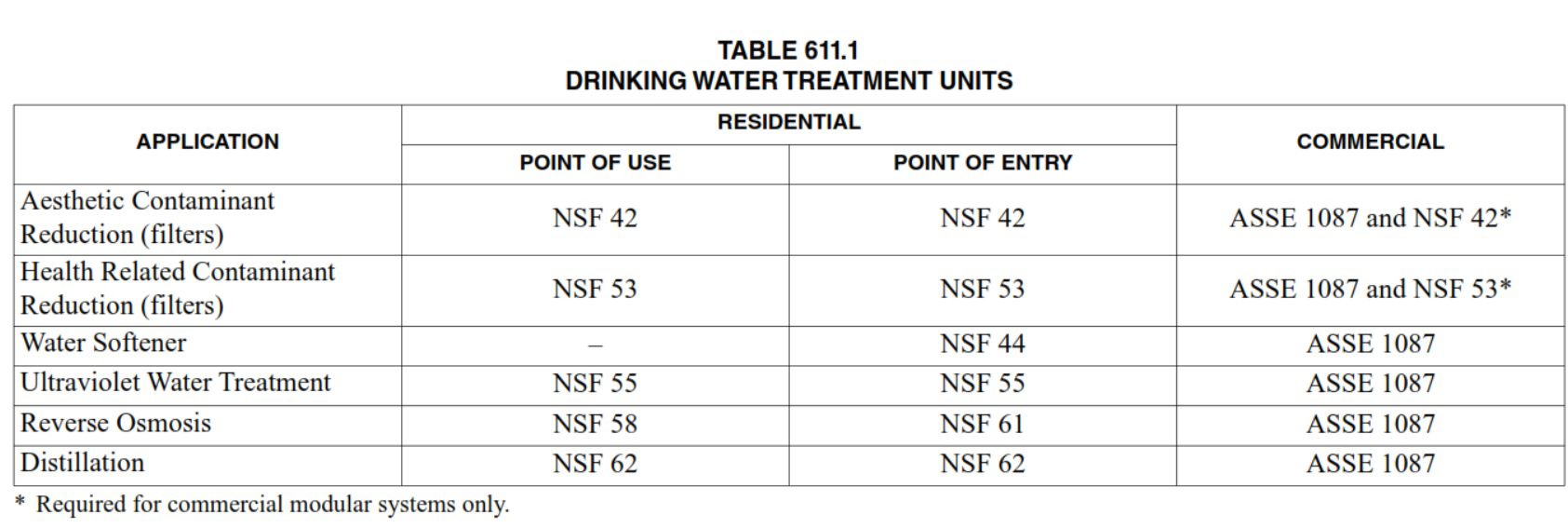

Table 611.1 is a new table that was added to provide the necessary standards for drinking-water treatment units.

Key Changes to the 2021 UMC

New Geothermal Energy System Appendix

There are many safety concerns that must be addressed when installing a geothermal system. Due to high public demand, a new appendix was added to the UMC for jurisdictions to adopt for the safe installation of geothermal systems. The UMC is the only mechanical code that provides an indepth and up-to-date code requirement to ensure the safe installation of geothermal systems. The appendix is separated into three parts for ease of use: Part I (general), Part II (closed-loop systems), and Part III (open-loop systems) and Part IV (direct exchange (DX) systems).

To properly design a geothermal system, it’s important to know the seasonal variation in the soil temperature as well as the soil’s inherent capability to store and transmit heat, namely its heat capacity and thermal conductivity. These soil thermal properties depend on soil porosity and moisture content. Therefore, any preliminary assessment of a potential geothermal heat-pump system will require knowing the soil texture and average groundwater level at the site.

Piping installed within or under a footing or foundation wall must be structurally protected from any transferred loading from the footing or foundation wall. A trench must be wide enough to allow for proper alignment of the piping system. Piping is best supported when it rests directly on the bottom of a solid, continuous trench for its entire length. Piping must not be supported intermittently by hard surfaces, such as rock or concrete, as this creates “point loads” on the pipe wall.

Ventilation Air Supply and Exhaust Systems

Chapter 4 of the UMC has been revised to be up to date with the latest ASHRAE 62.1 and provide ventilation requirements enforceable by any jurisdiction. It includes enforceable language for indoor air quality for residential occupancies. The UMC is committed to be consistent with the industry as well as making sure the public is always protected.

Chapter 5 also was revised to be consistent with NFPA 96 for commercial exhaust systems.

Hydronics

Chapter 12 was improved with the inclusion of safety provisions for hydronic systems such as simultaneous operation, temperature reading and tube fasteners.

Whether through our codes or standards development, IAPMO is committed to protecting the public. The Uniform Codes are published utilizing IAPMO’s proven turnkey philosophy, placing as much of the necessary information concerning installations as possible in one codebook. This philosophy eliminates the problems and confusion caused by using multiple codes to install or inspect the plumbing or mechanical provisions of a single installation or system.

About Hugo Aguilar

Hugo Aguilar is the senior vice president of Codes and Standards Development for The IAPMO Group; email: [email protected].