Increasing Profits and Winning More Work: GMF Industries’ Journey from Traditional to Model-Based Estimates

Estimating is inarguably one of the most-important and challenging aspects of any project, especially in today’s market in which the pressure is high to deliver competitive estimates in tight timeframes. At the same time, errors during takeoff, the volatility of material prices and complexities of predicting labor requirements increase the potential for risk.

Traditional estimating processes, which have evolved from hand-written documents and spreadsheets to on-screen digitizing takeoff, can be time consuming and leave a great deal of room for error.

Relying on a 2D drawing makes it impossible to identify potential conflicts and other factors that can’t be measured on a piece of paper. Unable to visualize exactly what a structure will look like after it’s constructed, estimators often lack confidence in the numbers. This leads to “padding” and, as a result, losing the competitive advantage that only can be achieved with tighter bids. Delivering an estimate that’s competitive and profitable is only possible if the amount of guesswork is limited.

The Solution

More often, BIM is being used in the estimating phase. It allows estimators to extract quantities directly from a model faster and with greater accuracy. BIM offers firms more information for estimating and bidding than they’d ever get from 2D drawings, and it allows them to more-effectively schedule projects. It also ensures that constructible data are captured for use throughout the project’s lifecycle and in bidding future projects.

One area where “estimodeling” is taking hold is in fabrication. Creating a model to generate highly accurate material quantities as well as detailed labor and cost data results in quicker takeoffs than traditional estimating methods, with an added value of data-rich, constructible models for greater accuracy.

From Traditional Estimates to Estimodeling

In 1982, with a single welding machine, Larry Norman set out to find work fabricating steel. He visited an amusement park 100 miles away to bid on a project, only to have the legitimacy of his business questioned because he didn’t have a business card. Larry returned with a freshly minted business card and walked away with a contract worth $1 million. Today, GMF Industries is a premier provider of structural steel design, fabrication and erection in the southeast United States.

Adam Norman, who now runs the business, joined the company in 1994. Through the years, he led GMF from manual to automated takeoffs and wanted to find a way to accelerate the company’s estimating process. When he heard about estimodeling, it was still a new concept, but the potential to estimate projects more quickly and accurately was intriguing.

“Our estimates were based on 2D drawings, so the workflow was both tedious and slow,” says Norman. “With estimodeling, we saw a massive opportunity to streamline the process and use 3D models to create extremely accurate estimates in less time.”

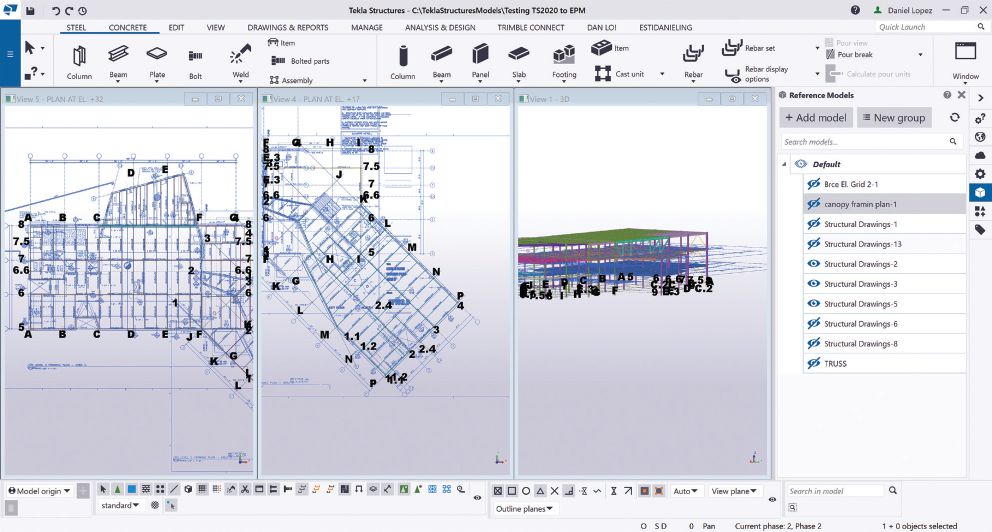

Norman tasked GMF’s most-experienced estimators with defining a new model-based estimating workflow using Tekla PowerFab. Today, estimators can quickly generate an IFC file that allows them to import a 3D model into Tekla PowerFab and use the model data to generate highly accurate material quantities along with labor and cost data.

Tracing over PDF contract drawings makes estimodeling easy for new users.

“On average, we used to bid a project every 10 days,” adds Norman. “Now, we’re bidding three projects each week. Estimodeling has not only increased the accuracy of our estimates; it’s also accelerated our workflow, which allows us to bid more projects.”

GMF stores standard materials and connections it frequently uses in Tekla PowerFab so when estimators import an IFC file, those standards are automatically attributed to the model. This accelerates estimating and ensures standards are incorporated in the bid.

“In the past, estimators would put generic representations of a material or connection in place rather than using GMF standards,” notes Norman. “The ability to drop in those standards makes our estimates more thorough because the closer we can get the model and workflow to reality, the better the steel is going to get fabricated and erected, and the more profitable we’re going to be on every project.”

Opportunities for Estimators to Advance

Change often is met with resistance, especially in the construction industry. Unsure of the reaction he would get from estimators who worked from 2D drawings their entire careers, Norman was surprised at how quickly the team took to estimodeling.

“Our chief estimator had never worked in a 3D environment,” he says. “He picked it up in less than a day and actually started improving my estimating workflow.”

It’s also expanded opportunities for less-experienced estimators. “Estimating is one of the most important parts of our business,” adds Norman. “Our estimators are very seasoned professionals who have fabricated steel in the shop and erected steel in the field. With automating takeoff and the ability to visualize what the final product will look like in 3D, we’re able to expand our team to younger estimators who are motivated to learn.”

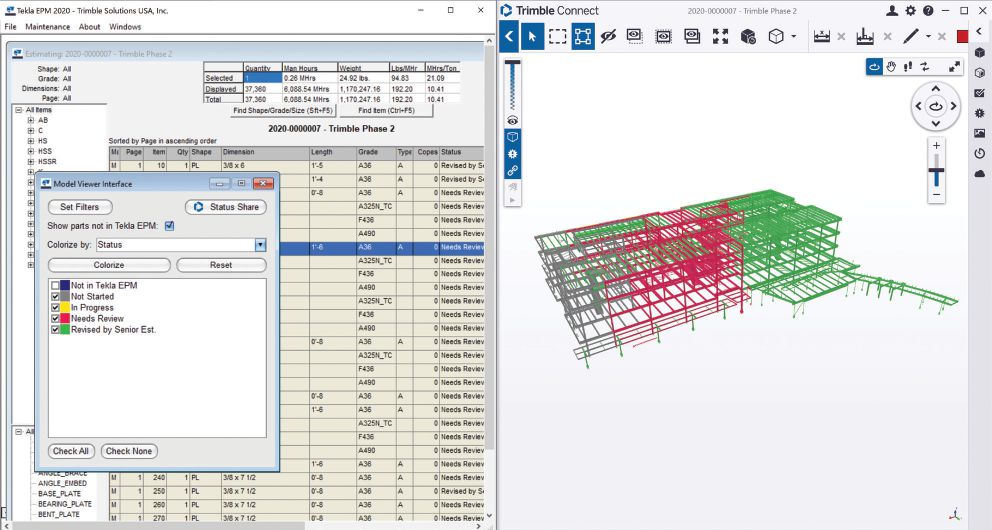

A user analyzes information from an estimate in Tekla EPM.

Trimble Connect enables users to know project status at any time.

Tighter Bids for a Competitive Advantage

Accurately determining the amount of steel needed, how long each phase of the project will take and the cost per project are nearly impossible to accomplish without the correct information on hand. In the past, creating a large volume of bids based on 2D drawings left a lot of uncertainties. GMF’s team of experienced estimators have the skills to compensate for unknowns, such as missing section cuts, but model-based estimating eliminated the need for guesswork.

“In the past, we could compensate for unknowns by putting contingencies in the bid, but in some cases that caused us to lose the job,” notes Norman. “Estimodeling has taken out those unknowns and given us the confidence to generate competitive estimates that optimize costs. When business development tells me we’re a percent high on a bid, I know what the true margin is and can adjust the bid.”

Detailed fabrication time translates to better planning.

Turning Around a Bid in Three Days and Winning

Early into its journey with estimodeling, GMF was approached to bid on fabricating and erecting 1,000 tons of steel. Because it was a nonprofit project with thin margins, bid accuracy and project efficiency were critical for success.

“Using the model, we were able to generate the estimate without adding contingencies to cover unknowns,” recalls Norman. “We had confidence that the hard bid was going to be a profitable number.”

GMF was given less than five days to turn around the bid, was awarded the project and started ordering material the following Monday. Not only did the model help turn out an accurate bid, it also helped GMF hit the ground running after the contract was awarded.

“After we won the job, we took the IFC file out of estimating and ordered the material cut to size,” notes Norman. “We had less waste and were able to hit mill orders straight off the estimate with 100-percent certainty we were ordering the right material. We purchased the material for just-in-time inventory. Some of it won’t even hit the ground because as it comes off the truck, we’re putting it straight on the beamline where it will move through fabrication.”

Model-based estimating can transform the way every firm bids and wins projects, making it possible to generate accurate and traceable quantities, update estimates on the fly, quickly deliver bids that lead to a competitive advantage and effectively communicate information downstream using the model.

About Ryan Vander Plaats

Ryan Vander Plaats is the MIS product manager at Trimble, Structures Division; email: [email protected].