Collaboration in Product Development Results in Better Designs

Good design is slow. Effective collaboration also takes time. According to Sara Pevaroff Schuh, the founding principal of Philadelphia-based SALT Design Studio, “Quality fights to be a full partner at the table with quick.” She’s right.

It may seem like an all-too-costly endeavor to return to the drawing board, but the familiar cliche rings true: you either pay now or pay later.

Green City, Clean Waters

Rob Woodman, senior stormwater engineer at ACF Environmental, witnessed firsthand the benefits of a time-intensive collaborative design process when designing a new product for Philadelphia Water Department (PWD) city inlets.

PWD needed a solution. It noticed safety concerns and inefficiencies during maintenance procedures for the filter bags used in its storm drain inlets. These “green” inlets are an integral component of Philadelphia’s “Green City, Clean Waters” program, an initiative that uses green stormwater infrastructure (GSI) to manage stormwater as well as reduce the volume of stormwater runoff and associated pollution entering Philadelphia’s waterways.

According to new research from the Sustainable Business Network of Greater Philadelphia (SBN), the 25-year nature-based stormwater management plan is an inspiring example of the triple bottom line (people, planet, profit) in action. Its June 2019 report, “The Economic, Social, and Environmental Case for Green City, Clean Waters: An Update,” highlights a correlation between a nature-based approach to stormwater management with lower crime and health costs as well as billions of dollars in economic impact (for more information, visit bit.ly/39pkJWD).

The plan is bold and effective, and it put Philadelphia on the map as a leader in GSI, but its continued success depends on the city’s commitment to maintaining the plan’s systems and mechanisms.

ACF conducted an inhouse study to evaluate a series of metal material types and thicknesses for their deflection and weight-bearing capacity.

Needing a New Product

PWD’s Green Stormwater Operations (GSO) Unit is responsible for the inspection, maintenance and repair of PWD’s GSI. The unit’s supervisor, Gerald Bright, reached out to ACF Environmental in search of a product that would improve upon the existing means of pre-treating city inlets. The existing wall-mounted units used to pretreat these inlet types lacked suitable capacity, and were difficult to install and remove.

“Maintenance staff would lay in the roadway, attempting to scoop sediment out of the filter bag by hand through narrow curb openings,” recalls Woodman. “The product was not working for them, and there was not an existing product that would adequately fulfill their goals relating to performance and maintenance needs better than they had already installed. A solution would have to be developed specifically for them, to satisfy their requirements and not put them at risk in the field.”

The only other option to hand-scooping sediment out of the bags was to remove the 4-foot-long filter bags from the inlet. But because of the product’s design and the inlet, this was nearly impossible without dumping sediment into the drains; the only opening was a 24-inch-diameter manhole, and the 4-foot-long bag couldn’t fit through without being tipped at a steep angle. Bright needed ACF Environmental to develop and implement a more maintenance-friendly solution.

A photo shows frame components of an early concept during pilot study/demonstration. It was later determined that fewer pieces were desired to speed up installation.

Collaborative Design Process

ACF Environmental carries a variety of inlet protection products that target pollutants in various types of drains and catch basins. However, after listening to PWD’s concerns, both parties initiated a collaborative design process to create the ideal solution. Conventionally, a company designs a product and then shops it out to a customer, but this design process was unique because ACF Environmental and PWD invited maintenance workers to join the discussions.

“Everyone had a voice at the table,” says Woodman. “By listening and including all team members in the process, we could brainstorm and develop ideas for a product that did not exist in the marketplace yet.”

New product design can be time-consuming and challenging. It takes patience for designers to revisit the drawing board with each issue. After each round of prototyping, the ACF Environmental team met with various staff members of PWD to review progress and determine necessary modifications. According to Woodman, “Feedback from all team members was considered a gift—whether they were a maintenance worker or the senior design engineer. We discussed every piece of feedback.”

ACF Environmental completed a prototype for a new high-flow geotextile filter bag that would resolve issues with the existing filter bags, including premature failure during placement or maintenance. Although the expected lifespan was more than a year, the existing filter bags tore easily, and maintenance workers needed to replace them every few months. The geotextile bags would tear along the centerline seams when the weight of the accumulated sediment applied stress to the seam.

Based on negotiations among design-driven requirements (flow rate and particle size) and maintenance-driven requirements (volume of capture and bypass capacity), the team selected a woven monofilament geotextile middle filtration layer for the filtering element. It added polyethylene mesh on both sides of the woven monofilament geotextile to provide additional protection from tearing when the unit was cleaned in place with a vacuum or removed from the inlet (which often included workers dragging the sediment-laden unit to the emptying location). ACF Environmental could develop the new high-flow geotextile bag with no centerline seam and improve the bag to frame connection points.

After ACF Environmental’s manufacturing and design teams completed the bag, they brought on Fabco Industries, a Long Island, N.Y.-based stormwater filtration and product innovation company that specializes in metal fabrication, to design the unique PWD-specific aluminum frames.

PWD was experiencing issues with its current metal frames bending or breaking during maintenance, causing sediment and trash to fall into the drains. It was critical that the new frame could support the load of a full filter bag during removal. The new frame accomplished this and reduced the number of wall anchors required during installation. Each of the new frames also provided adjustability, so maintenance workers could accommodate minor conflicts and drain-size variations in the field.

The Final Product

In December 2018, ACF Environmental and PWD unveiled the new green inlet filter series: PWD StormSacks. PWD’s maintenance staff no longer have to lay in the street, because StormSacks are easy to remove and can be cleaned with a vacuum.

“The new StormSack product was a marked improvement over existing products in regard to capacity, durability and ease of maintenance,” adds Bright. “It allowed us to maintain city inlets using mechanized equipment as we do for other inlet types, which will result in an uptick in productivity for our Inlet Pretreatment Maintenance crews.”

“Using feedback from all members of the team, including feedback from key program maintenance consultants like AKRF, we developed a safer, more-efficient process for inlet maintenance by producing a high-performance, long-lasting and cost-effective set of inlet filters,” notes Woodman. “Collaboration is a crucial element of innovation.”

Many cities are paying attention to Philadelphia’s trailblazing “Green City, Clean Waters Program,” including New York City. After the installation of the PWD StormSack, the NYC DEP and its assigned consultants reached out to ACF Environmental to help develop inlet protection devices for its right-of-way bioswales and infiltration trench designs that meet their performance and maintenance needs.

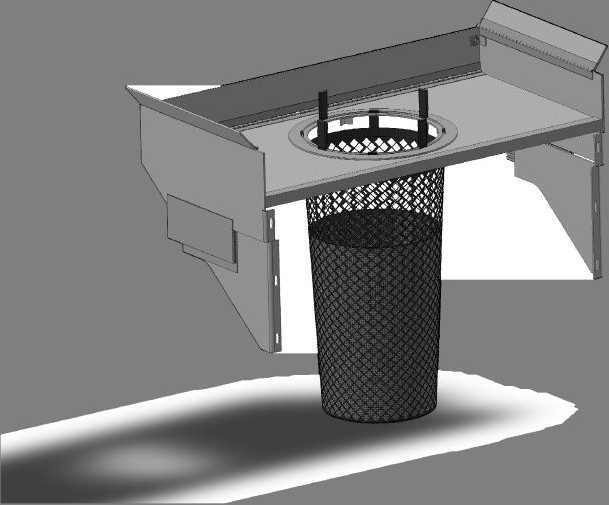

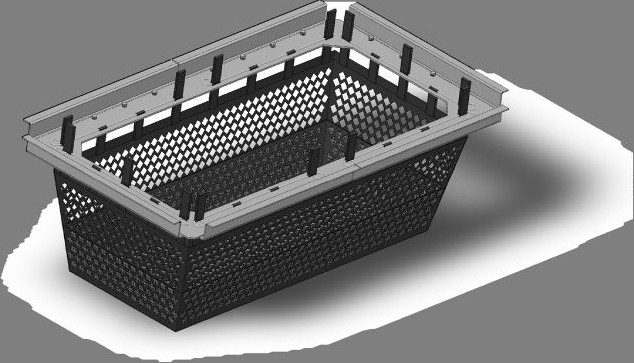

Solidworks renderings show the Green City Inlet Filter (PWD StormSack Type P, above) and the Green Highway Inlet Filter (PWD StormSack Type M, below). Fabco Industries

“Through working with a series of cities, we realized that every city is unique and calls for unique solutions,” says Woodman. “From a design side, we consider the obvious variables such as the size of tributary areas to drains, the size of drain grates/castings and pollutants. Sometimes the main concern is more than sediment or trash.

“There are other pieces to the puzzle though, which include a city’s experiences with inlet protection, its maintenance capabilities (including available equipment), desired frequency of maintenance, aesthetics, public perception, and a variety of key program personnel opinions and perspectives,” adds Woodman. “A collaborative process is the only way to have a positive impact on the long-term performance, success and cost of ownership for green infrastructure programs.”

Photos show final versions of the Green City Filter unit (PWD StormSack Type P, above) and the Green Highway Filter unit (PWD StormSack Type M, below) installed in Philadelphia drains.

PWD will closely monitor the enhanced performance and optimized maintenance processes its new PWD StormSack will provide. Just as all voices were heard during the design process, ACF Environmental expects tweaks to continue as additional lessons and feedback from the field return to the team. It plans to continue to collaborate on and evolve the PWD filter-bag solutions.

Referencing an earlier edition of the “Green Streets, Clean Waters” design manual, Howard Neukrug, the former PWD commissioner, said, “The key to the success of green streets is to develop a seamless process whereby stormwater management, street engineering and landscape design come together to produce a functional, attractive and cost-efficient project.”

This is clear through the design process of the new PWD StormSack. It’s worth it to put in the time to protect the performance of these systems as well as the public investment in GSI, especially because the social, economic and environmental return on investment for a nature-based approach is necessary and welcomed in Philadelphia and beyond.

About Bradford Bucknum

Bradford Bucknum teaches at Temple University and Rowan University, and is the former communications manager for the Sustainable Business Network of Greater Philadelphia; email: [email protected].