FiberPILE Shores Up United States Ferry System, Replaces Fracture-Prone Timber Piles At Jamestown-Scotland Terminal Facilities

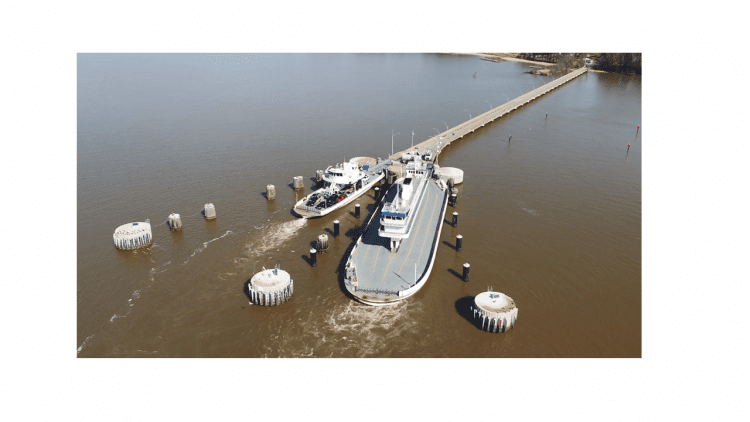

DAYTON, Ohio – Growing passenger traffic, larger ships and stricter environmental regulations have prompted ferry owners to consider alternatives to fracture-prone timber pile dolphins. The Virginia Department of Transportation (VDOT) invested in Composite Advantage’s fiber reinforced polymer FiberPILE system for its Jamestown-Scotland Terminal facility. The agency cited greater cost efficiencies due to FRP’s longer life cycle, reduced service interruptions and safer operation. In 2018 VDOT replaced 296 timber piles with eight large-diameter FRP monopile dolphins at one-third the lifecycle cost of wood.

The state’s only toll-free ferry runs 24 hours a day, 365 days a year including all major holidays. It acts as a movable bridge for Virginia State Route 31 travelers that need to cross the James River. FiberPILE products are fabricated to high strength-to-weight ratios capable of handling overall ferry crushing loads and adverse wind conditions.

“We fabricated the 100-foot-long FRP monopiles with multiaxial E-glass reinforcement,” explains Composite Advantage President Scott Reeve. “Fifty-nine percent of the glass fibers used in the lower 80 percent of the pile were orientated at 0 degrees [parallel to the longitudinal axis of the pile]. Eight percent of the glass fibers were given a 90-degree orientation with the remaining fibers oriented at ±45 degrees. Glass fibers for the top 15 feet of the pile [focused on the hoop direction] were manufactured with eight percent at an orientation of 0-degree, [parallel to the longitudinal axis of the pile], 59 percent at an orientation of 90 degrees and the rest of the fibers were given an orientation of ±45 degrees. Wood has a 42 ft-kip energy absorption. This combination gives our monopiles an energy absorption of 585 ft-kip energy absorption.”

Hollow construction, light weight and low driving friction also make FiberPILE attractive to contractors. Following setup which took a day, contractors were able to drive a 100-foot monopile 25 feet into the river bottom in approximately 20 minutes with minimal disruption. Eight FRP monopiles replaced 37 wood piles.

Composite Advantage supplies innovative fiber reinforced polymer (FRP) products for major infrastructure markets. To create its engineered solutions, CA pairs progressive designs with its capability to mold large parts, perform on-site assembly, and support customer installations. The supplier has been developing lightweight, high-strength, cost-effective FRP goods for structurally demanding applications and corrosive environments since 2005. Many of these products have paved the way for first-time use of FRP composites in infrastructure, rail and water applications because of their performance attributes. The supplier’s comprehensive lineup includes bridge decks, trail bridges, cantilever sidewalks and rail platforms to fender protection systems, pilings, naval ship separators and other waterfront structures. CA is member of the Creative Composites Group, a subsidiary of Hill and Smith Holdings PLC.

Visit www.compositeadvantage.com or contact Composite Advantage at 937-723-9031 or [email protected].