Interview with Greg Bentley, CEO, Bentley Systems: The Continuing Evolution of Engineering Software

Informed Infrastructure Editorial Director Todd Danielson (right) interviewed Bentley Systems CEO Greg Bentley (left).

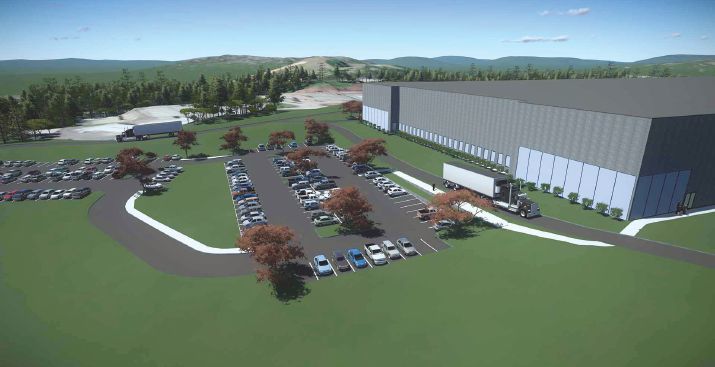

In April 2019, Informed Infrastructure Editorial Director Todd Danielson went to Bentley Systems’ corporate headquarters in Exton, Pa., (photo below) to interview its CEO, Greg Bentley. The full 45-minute interview can be viewed above or at wp.me/p8dJln-cyJ, but we also wanted to include some excerpts in this “5th Anniversary Special Edition” on “Smart Engineering.”

Danielson: Digital twins seem to be the next evolution in design and construction. How would you summarize what a digital twin is, and how does that differ from BIM or reality modeling?

Bentley: Todd, I like the word “evolution.” We say at Bentley Systems: “Going Digital.” Some people say “digital transformation” as if something will be over and done with.

I think we’ll always be advancing and going digital, and I think digital twins represent advancements from or of BIM. Also, you mentioned reality modeling. It’s a convergence, but an advancement of reality modeling as well.

We tend to do BIM for a particular purpose; usually, that’s somewhat a limited purpose. But when we think of a digital twin, our own twins are live, and they’re “evergreen.”

So, to think of digital twin for an infrastructure project that becomes an infrastructure asset; it’s the same digital twin, it’s evergreen over the project and asset lifecycle, and it has to correspond to the physical asset.

We say that’s about capturing the digital context of the project or the asset, and we do that through reality modeling. Reality modeling uses overlapping photographs and imagery or laser scanning and processes it into a reality mesh that’s engineering-ready. Reality modeling is the stuff and substance capturing that digital context, including the environs and surroundings and utilities and so forth for an infrastructure project.

And then we say if it’s going to be a twin, it needs to explain and provide insights and understanding into the behaviors of what we’re delivering or operating in infrastructure, and that requires veracity and explanatory capability.

To me, the way we accomplish that is for our digital twin to be comprised of digital components that understand themselves. They are the stuff of BIM, but we can also glean digital components by classifying the reality mesh with machine learning.

You can be digital, but it’s not a twin if it’s not synchronized to the changes that occur over a project and an asset, so I like to call that the “digital chronology.” It’s taken technology for all of these to converge, just at this time, to be able to offer and have the advantages of digital twins for infrastructure assets.

Danielson: What are the main benefits of digital twins, and how can they help develop smart or sustainable cities, projects, or buildings?

Bentley: Cities are made of projects; that’s how they’re developed and delivered. Projects always start with a site. And, I’d like to use a site project as an example for the benefits of digital twins.

Think of the phases from conceptual to preliminary to detailed design, and your project would start with a digital context of a site and terrain and zoning restrictions, and so forth. It would start with a reality mesh that’s been classified, and that’s the stuff to which you then engineer the digital context and benefits that occur in a digital twin approach.

Then, during the conceptual stage, you’re “conceptioneering” the tradeoffs in coverage and drainage and grading, and OpenSite™ Designer has the digital components to cost out and work out the near optimums for engineers to choose from, permitting a full space of possibilities to be explored, including the geotechnical considerations, and the civil and structural engineering as you consider the particular building when you get to preliminary and then final designs.

And as the project would move on to construction, the benefits are being able to have the immersive visualization where everyone understands the project in the same way.

It ends up being enlivened, if you like, with a simulation of the BIM designs and vegetation and so forth, so it can be evaluated as well by the owners. Thanks to immersive visualization, it’s more intuitive and easier to use and adopt than would be the separate technologies of BIM or reality modeling.

Danielson: There have been other claims in the past that were expected to digitize the construction workflow, and it didn’t exactly pan out. Why do you think digital twins are going to accomplish that goal?

Bentley: With “going digital,” there will always be further advancements, but I would say that digital twins mark a milestone, describing when the virtual space in which engineers work corresponds to the physical space in which constructors work. They all have the same space and time reference, and the time reference is so important in construction.

The project digital twin is so important because if you have only a BIM model and then the constructor creates their own 3D model, it’s leaving behind the intelligence that could have been beneficial during the live and evergreen stage of the asset once it’s operated and maintained.

But construction, of course, is increasingly about logistics and fabrication and modularization and so forth, and it’s the work packaging that brings that all together that the digital twin makes possible. It allows everyone involved in the project to similarly understand, through immersive visualization, the continuous and comprehensive status reviews that become possible.

Todd, you may recall at our last infrastructure event in London, a major project was presented that’s taking place here in the state of Pennsylvania. It’s a huge multi-billion-dollar project on 1,000 acres and where continuous surveying occurs—reality modeling every week—so BIM models of the industrial project can be compared to the construction status.

When you have captured the digital context so completely and comprehensively, it’s possible to consider and provide resilience against further risks that could occur on the project. So, by the way, our OpenFlows™ FLOOD software can now be utilized to simulate the impact of expected weather and rainfall because there is concern about how flooding would jeopardize the construction schedule and construction aspects.

You can simulate, with our LEGION software, the pedestrian and vehicle movements on the site, which are so constraining otherwise.

When we talk about smart and sustainable cities, these resilience risks—the flooding, seismic, wind, putting this all together—it’s not “Do we finally have it fully done?” No, these are just new potentials that are possible.

Bentley Systems’ Open Cities Planner was used by Helsinki to create a full city model.

Danielson: Another technology that’s really changing things is open-source technology. A lot of your newest products use the word “open” in the names and branding, how has open-source technology changed Bentley’s vision and how they’re doing things?

Bentley: Our vision is for “open,” for these solutions to be open to the user’s choice of tools and repositories. If you’re working in software development today, you are daily immersed in and exposed to and taking advantage of open-source components and platforms, all the way to the collaboration hubs you use together and that Microsoft is now incorporating. IBM made its biggest acquisition ever, and it was an open-source software company [Red Hat]. Software developers have learned that when there is an ecosystem and a community working together, and you have contributors and reviewers and so forth, it turns out to be a fantastically productive environment.

We’ve had some containers for self-description: iModels, we call them. Now they go so far as to create digital alignment between the semantic aspects of what different disciplines and phases can be working on in an infrastructure project and enable them to be referenced and synchronized together and their changes synchronized across a hub. We call that an open-source platform. It is literally provided in open-source, so our user organizations can apply their own skills, their own advancement strategies in immersive visualization. Some will call that mixed reality. They have teams to work on analytics and require visibility into the engineering data.

It’s been dark up until now, obscure formats, but if you can bring it into a hub digitally aligned, and then be able to run analytics across projects or a portfolio of projects in an open-source schema and environment and platform, it is going to change a lot about the way we think of things in infrastructure projects and construction.

We don’t even realize how much we’ve presumed that all our data is dark and inaccessible. It’s just because it’s in specialized engineering formats, but when we can bridge from those formats, by way of a cloud-service hub that has digital alignment and immersive visualization, and continuous and comprehensive status reviews, “open” is going to win.

Danielson: To highlight open-source technology, what would be some differences or similarities in an engineering firm that uses mostly or all Bentley products vs. one that’s using a variety of products? How might some of the open-source technologies be different in those situations?

Bentley: I think each engineering firm, to some degree, is saying we need to improve our business model to have our own intellectual property to our means and methods or our stock in trade. How, in going digital, do we differentiate ourselves? An open-source platform lets you apply your immersive visualization strategies, your particular devices and ways of working and collaborating, but starting from your project universe and the disciplines and tools you use now and especially analytics visibility, the Big Data generated.

One example is machine learning. From continuous surveying of sites, including for design and construction, you train the software to recognize and classify the digital components you find and use on the site.

When it does that, it can tell you about their relative correctness and progress. You start with a platform that allows you to begin learning and training from your existing projects.

Software developers are standing on the shoulders of open-source platforms and are able to modularly improve things without starting from scratch. You don’t need to build the foundation. You can simply increase and improve and particularize it for you and your ecosystem.

ContextCapture, another Bentley product, helps construction sites build 3D reality models from georeferenced photographs.

So it’s our ambition and aspiration to be part of every project with our cloud services that enable this federation to take place. We call this iTwin® Services: the digital alignment, the immersive visualization and analytics visibility that will be ultimately applied by the user organizations themselves. The engineers that up until now have been doing tasks that can be automated in modeling and drawing productions are, in the future, going to be working with data to apply their skills and background to analytical solutions and improvements to make our environment and economies more efficient through advancing infrastructure and the platforms to do that.

We want to open up all this dark data, whether it’s from our own tools or a mix of tools.

OpenSite Designer is part of Bentley Systems’ collection of “open” software.

Danielson: Another technology that’s been talked about for a while and is finally catching on is “time,” the 4D element. Bentley Systems has its SYNCHRO Software, but how easy or difficult is it for people to take past project or past work and try and put in that time element? Is it too late for that, or can it be added in after the fact?

Bentley: You ask a very interesting question: Your project’s completed, can we talk about 4D from those projects? That was exactly the point raised when I talked to a major engineering firm, global firm, CEO, and his head of digital innovation. He said, “In ProjectWise, we have all the projects we’ve done. Can we learn from those and learn across those what worked and didn’t, and how we can get better?”

So I went back and discussed with our team here, and we think we should be able to create the timeline of changes, the digital chronology for projects of the past, and then apply analytics to what those changes are.

This notion of learning from what we’ve done, opening that dark data and to have that dark data because ProjectWise is used for collaboration across the project, and across many firms’ full project portfolios.

We think there’s potential in that, this notion of chronology and a time slider. We want to make it intrinsic to how you interact with a digital twin, this notion that it’s live and evergreen. That’s what makes it a digital twin, but we can learn from the changes. We can analyze the risks as they were introduced and overcome, and it’s so vital to improving our project’s performance.

We want to make that very intrinsic. We think every digital twin should have its digital chronology, because the changes are of the essence.

Another technology advancing very quickly is machine learning from continuous drone surveys. So, you can teach our ContextCapture software what you want to recognize and classify in your digital context or your construction scene. You can recognize and classify the digital components much better, much more quickly.

It’s really a different concept for a software developer, which has been thinking in terms of introducing logic and functionality. Now, we just introduced this platform aspect, and it becomes smarter on the user’s projects and portfolio.

Danielson: Mixed-reality technology, such as the Microsoft HoloLens, is another “futuristic” technology that’s nearing mainstream workflows. How do you see that evolving, and how will that bring more people into the design, construction, and management processes?

Bentley: I think Microsoft has defined the mainstream differently. Instead of its video gamers, it’s looking at industrial applications such as 3D and 4D immersive visualization on construction projects. That’s where we have helped demonstrate this vision, so everyone on the project has the same understanding of the expectations and the timeline, the logistics, the advanced work packaging, and the work breakdown. It’s all expressed in the same way between the virtual and the physical—the same space and time references. We call it advanced work packaging.

Essentially, when there is the same immersive visualization across the project team, there is one version that can synchronize the veracity of the project more certainly.

About Todd Danielson

Todd Danielson has been in trade technology media for more than 20 years, now the editorial director for V1 Media and all of its publications: Informed Infrastructure, Earth Imaging Journal, Sensors & Systems, Asian Surveying & Mapping, and the video news portal GeoSpatial Stream.