Latest Migratory Inhibitor Technology- Powerful Corrosion Protection of Post-Tensioned Structures!

MCI®-309 is a powerful Vapor phase Corrosion Inhibitor powder for corrosion protection of ferrous metals and aluminum in recessed areas, interior cavities and voids. It provides an extremely efficient dry method protecting metals within an enclosed space. The MCI® vaporizes and adsorbs on the metal surfaces, reaching all exposed areas, including recessed sections and interior cavities. This mixed inhibitor provides protection to both the cathodic and anodic sites of metal. MCI®-309 does not affect physical properties of concrete or grout (set time, strengths, etc.), and it is safe for high tensile strength steel (will not cause hydrogen embrittlement).

Corroding rebar in deteriorating concrete often causes costly repairs, financial losses and serious injuries. MCI® technology offers the most contemporary solutions on the market to prevent this from happening. Cortec® MCI® products for concrete maintain structural integrity, rehabilitate vulnerable structures, and alleviate environmental concerns. MCI®-309 creates a monomolecular inhibiting layer and enables up to 24 months of continuous protection.

Protected surfaces do not have to be cleaned prior to concrete or grout placement. If the MCI® layer is disturbed by moisture or by opening the enclosed space, the layer is replenished by continuous vapor redeposition. MCI®-309 does not contain silicates, phosphates, nitrites, or heavy metals. This easy to apply powder requires little or no surface preparation and prevents further corrosion of pre-coated and painted surfaces. The layer does not need to be removed prior to processing or use. The powder can be removed by air gun or water.

APPLICATIONS

- Segmental concrete bridges tendons

- Post tensioned box girder bridges

- Tubular structures, pipes, and vessels

- Equipment protection after hydrostatic testing

- Parts, components, and completed assemblies during shipping and storage

- Prestressed tendons

- •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

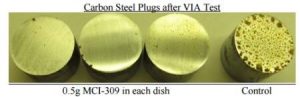

MCI®-309 passed the VIA test per CC-027 (the method specifies testing 0.5 g of inhibitor of interest).

Cortec® has had successful applications of MCI®-309 Powder for Post Tensioning (PT) Cables. A recent application was conducted on rebuilding of the Wacouta Bridge in South St. Paul, Minnesota, the widest bridge in Minnesota with regards to the number of lanes.

Punalu’u Stream Bridge in Hawaii is located steps away from the Pacific Ocean and the atmosphere is highly contaminated with chlorides and sulfuric dioxide from the volcano. The acid rain combines with chlorides to create a very corrosive environment. Injection of MCI®-309 with air was performed just after the post tension cables were placed. The powder did not need to be removed when the post-tension chambers were injected with grout and were readily absorbed by the grout. MCI®-309 was used because it enabled protection to the steel surface, greatly extending the expected service life of the structure. It provided excellent corrosion protection in an aggressive environment.

Other applications of MCI®-309 include the Sunshine Skyway Bridge, San Francisco Bay Bridge, Des Plaines Bridge, the Memorial Bridge in Croatia, and the Colorado Bridge (Hoover Dam By Pass).