HR Wallingford Nears Completion on State-of-the-Art Marine Test Facility

Work to create one of the world’s largest maritime test facilities has entered its final stage following the completion of a £3 million development at HR Wallingford’s site in Oxfordshire, UK. Keys to the new 1,600 m2 building were presented to HR Wallingford by Kier Construction on Thursday 17 April, and work has now begun on the fit-out of specialist facilities within the building to enhance the company’s scour, sediment and structure modelling capabilities.

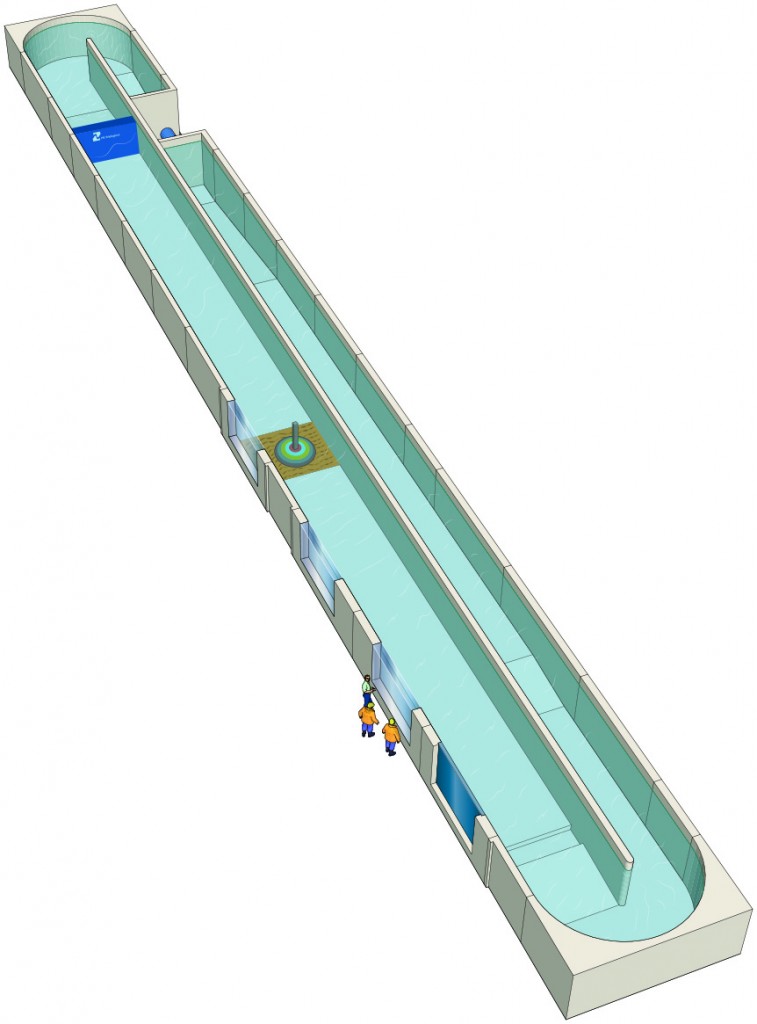

HR Wallingford works with organisations around the world to solve problems involving water and its interaction with structures and the environment. The new building houses the Fast Flow Facility, a unique, dual channel flume which will deliver a world-leading capability in wave-current-sediment modelling. The 75 m long, 4 m wide flume will be capable of generating waves up to 1 m high and currents of up to 5 m3/s. It will hold up to 1,000,000 litres of water, a volume equivalent to 12,500 average sized baths.

Dr Richard Whitehouse, technical director at HR Wallingford, and manager of the facility’s development said “Understanding the complex ways waves, currents, and sediments interact is vital to the successful delivery of projects in the marine environment. The Fast Flow Facility will allow our scientists and engineers to examine these problems at a larger scale and in more detail than has previously been possible. We will be able to more effectively optimise designs for our clients and help them to minimise the water based risks for their projects.”

Mark Liddiard, energy business manager, said: “The Fast Flow Facility will deliver real benefits to the marine renewables sector. Developments in exposed marine environments are high risk: fast currents, deep water and energetic waves present significant technical challenges. The ability to model large structures and arrays, without compromising on scale, mean that we can help our clients to plan, install and maintain their assets in the most efficient way possible.”

Dr Keith Powell, director, HR Wallingford, said: “Our physical laboratory test facilities already provide a global service to support water related engineering projects. It is an extremely exciting time at HR Wallingford as the Fast Flow Facility will significantly enhance our modelling capabilities, helping us to expand our role in the renewable energy and maritime sectors.”

The building’s official opening will take place in October 2014. The purpose built building will also become home to HR Wallingford’s world class Ship Simulation Centre with four real-time, 360 degree field view simulators, including two tug bridge simulators, complementing the newly upgraded four-simulator facility in Perth, Australia. The building will also house an expanded manufacturing space to increase product design and fabrication capabilities.

Key features of the Fast Flow Facility:

- Main working channel size of 70 m by 4 m

- Water depth range 0.5 m to 2 m

- 1 m deep test pit for sediment studies

- Flows up to 5 m3/s with tidal capability

- Significant wave heights up to 0.5 m and maximum wave height 1.0 m

- State of the art monitoring and data collection instrumentation

- Versatile facility for general science and engineering hydraulic and sediment research

About HR Wallingford

HR Wallingford is an independent engineering and environmental hydraulics organisation. We deliver practical solutions to complex water-related challenges faced by our international clients. A dynamic research programme underpins all that we do and keeps us at the leading edge. Our unique mix of know-how, assets and facilities includes state of the art physical modelling laboratories, a full range of numerical modelling tools and, above all, enthusiastic people with world-renowned skills and expertise.