Are Your Construction Projects Under Control? Five Steps for Modernizing Cost and Schedule Management

“Incompetency at every level.” Definitely not the type of expression that should be associated with a $9 billion project. But that’s the case with the now cancelled construction of the two nuclear reactors in South Carolina of which the political, social and economic effects will be felt long after the last workers leave the now-defunct site.

This situation led many to use the all-too-familiar phrases: “Haven’t we been here before?” closely followed by “Why haven’t we learnt from these experiences?”

The Status Quo Has to Go

Simply put, the status quo has to change. Our approach is flawed, risky and wrought—now more than ever—with political and social fallout in addition to the pure economic side of things. The aforementioned example in South Carolina had myriad problems, but, most importantly, the project lacked a way to integrate labor, supply chains and budgets. Without this, no stakeholder—from the executive suite to the regulator’s office and the field—had a clear picture of the project’s performance.

The industry has made progress, by leaps and bounds, in the last few years across a number of broad areas. The improvements extend to process management and technology adoption, which are essential to keep pace with the growing complexity of our business. But one of the most crucial components—project controls—remains entrenched in the past. Why do companies insist on running major projects with spreadsheets and email?

The Case for Change

Consider how long it takes to gather, verify and maintain cost information, and then link it to project data. Time is money, and hundreds of daily decisions often are made with inaccurate or outdated information. Siloed systems impede collaboration and the ability to leverage networks. Spreadsheets and legacy solutions (many of which are reaching their end of life) are disconnected, and interactions among internal and external project team members are locked in emails and attachments. In this disjointed environment, populated by islands of information, change can be catastrophic. Productivity suffers, schedules slip and unexpected costs run out of control.

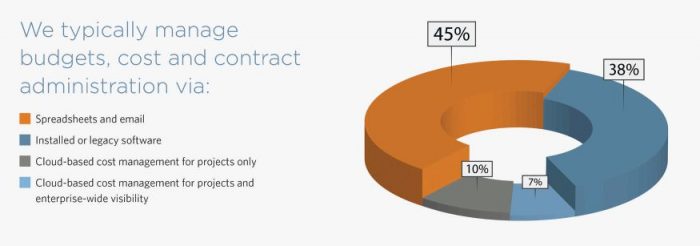

(Source: How Modern Project Controls Challenge the Status Quo, Aconex 2017)

And there’s data to support these claims. In a recent report, Aconex found that a combined 83 percent of people surveyed cited spreadsheets and email (45 percent), and legacy software (38 percent) as the primary systems used to manage budgets, costs and contracts. Maintaining the status quo isn’t the answer; success lies in the 17 percent who have invested in modern, cloud-based project-control solutions (see chart, below).

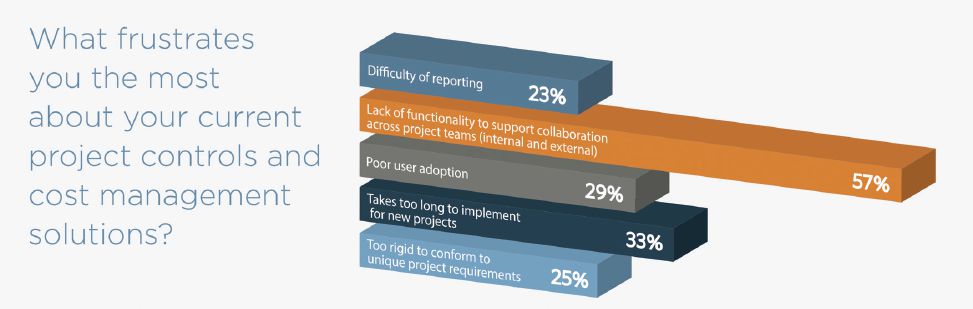

Another area of concern that surfaced in the research was a general frustration with not being able to effectively collaborate with external parties. Out of 174 responders, 57 percent agreed that the inability to support collaboration between internal and external teams frustrated them most about their current project-control solutions. After all, with the highly networked nature of the business (i.e., multiple internal and external teams) not having an easy way to share changes, contract information, drawings, etc., impacts the ability to get the work done (see chart above).

Finally, adding to the woes of executives is the inability to access accurate and timely information. One needs to pause and reflect upon the impact of decision making when only 26 percent of stakeholders feel they have access to such information. When put in the context of having to present to executives or regulators, this is mission critical.

Where Do We Go from Here?

Fortunately, the only direction is up. Custodians of capital (e.g., owners, owner’s reps, EPCs, contractors, etc.) can modernize their approach to project controls. And there’s a growing willingness to embrace new technology to drive process improvement.

The following are five things that a modern projects-controls solution can enable to solve many of the problems plaguing the industry today:

1. Single source of the truth. Reality sets in when it’s time to report out—to find information to support a dispute or make a decision. There’s no single place to search, and the true cost of disparate systems becomes clear. This is when the benefits of a single, flexible project-control system (that also supports collaboration of an entire project team) become evident.

2. Connected schedule and cost. When schedule and cost are isolated to their own silos, visibility of the true effect of change is impossible. It makes for incomplete processes, exposing the possibility of errors due to reliance on manual links between departments, groups and teams. For example, to evaluate the potential impact a change order might have on the overall project schedule, the scheduler often needs additional context and related documents. Capturing the entire lifecycle of a process and eliminating manual exchanges reduces the risk of error and increases efficiency.

3. Flexible and scalable systems. When discussing standards and best practices, it’s not uncommon to hear “that’s not our process; we do it this way, because the software doesn’t support how we should be doing it.” Simple, “out-of-the-box” tools are good for a quick start, but they will not support your business as you grow. You can’t scale and grow your operation without flexible, easily configurable systems. Leaders always are on the lookout for ways to improve, incorporate lessons learned into future projects and pursue new types of work; and they rely on mission-critical systems such as project controls to have the flexibility to move with them. There’s no “one size fits all” option for project controls; there are too many unique variables that require flexibility.

4. Informed decision making. How can you make the best decision when you don’t have all the facts? A project has thousands of decision points along the way that combine to make it either a success or a failure. But getting the data often is a complex and time-consuming process. Business doesn’t stop to allow information to be gathered and compiled. True efficiency lies in instant, real-time reporting from a single source of truth.

5. Effective change management. The best-run projects plan for change—from initiation to resolution—and good documentation is critical to avoid disputes. Effective change management requires integration of cost, schedule and processes—changes affect the entire project and not just one area. Change doesn’t occur in a vacuum; tracking its origin is just as important as managing its impact on cost and schedule. A single change can involve a trail of drawings, meetings, RFIs, submittals, quotes and negotiations along with other correspondence.

The Future Is Bright

Are we doomed to repeat the failures of the past? The future is up to us, and we now have the capabilities to make major improvements in how we plan and execute projects. I was encouraged recently by a project-control event I spoke at in Sydney, Australia, where many of the discussions revolved around the importance of unifying people, process and technology.

In fact, Pedram Danesh-Mand, president of the Risk Engineering Society in Australia, told me that “With all these sophisticated project interfaces and technical complexities, it’s essential that the next generation entering the profession have not only a grounding in project-control best practices and processes along with the leading software, but also a high level of personal and soft skills to enable them to achieve success for their projects.”

I couldn’t agree with him more, and I endorse the idea of “competence at every level.”

About Guy Barlow

Guy Barlow is the global commercial director, Connected Cost, Aconex; email: [email protected].