SynTech Bioenergy Announces Advances in Biomass Renewable Technologies

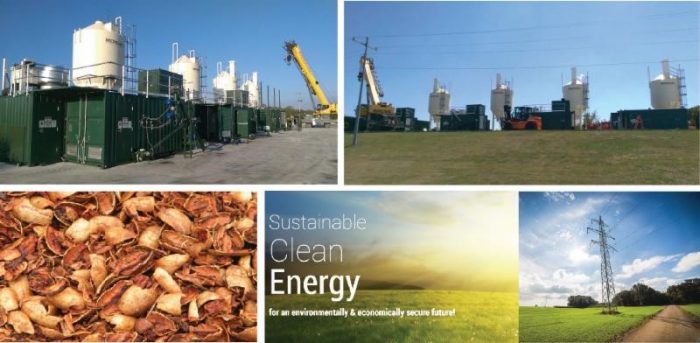

Denver, Colo.: SynTech Bioenergy, a Denver based renewable energy technology company, is committed to delivering distributed clean energy through advanced thermal conversion of biomass and other wastes around the globe. The SynTech BioMax® systems are small, immensely scalable, easily transportable and affordable. As of May, SynTech has completed the installation of its newest facility which will convert pecan shells into electricity in Texas.

Five similar plants are currently operating on walnut shells in California; the first plant dates back to 2008. SynTech is on an aggressive growth curve and is also preparing three additional units for a new California customer, and is well into manufacturing of its first unit for the Japanese market.

BioMax® output is scalable from 165kWe to 1MWe and is modular, containerized, easily transportable, remotely operable and powered by a variety of abundant biomass including wood wastes (chips and pellets, etc.), nut shells (walnut, pecan, coconut, pistachio, macadamia, etc.), fruit pits (olive, avocado, prune, date, etc.) and a host of other readily available biomass feedstocks.

Heat created in the Texas process is used to dry the pecan shells and the system creates no waste. The only byproduct of the technologies is organic biochar, a soil amendment (fertilizer) which aids plant growth,reduces the need for irrigation and increases global food supplies. Biochar can be further processed to produce activated carbon for use in air and water filtration as well as graphene, an industrial material that is ultra-light, flexible and

200 times stronger than steel.

SynTech’s closed-loop process eliminates problematic site-produced waste shell by converting it to distributed, continuous and uninterrupted base load electricity. This electricity powers the customer facility and any excess electricity is fed back to the grid.

From the feedstock entering the system to the electricity produced by the installed generator sets, the BioMax® system is carbon negative. Each system sequesters 1.07 ounces of carbon per kWh, amounting to approximately 35 tons of sequestered carbon each year, safely storing this carbon that would otherwise be released into the atmosphere. In stark contrast, natural gas power plants release approximately 19 ounces of carbon dioxide per kWh.

“The core of our process is what happens inside SynTech’s fully automated BioMax system,” explains Chief Executive Officer Wayne McFarland.”The Texas facility utilizes proprietary advanced thermal conversion technologies to convert 13.2 tons of pecan shells per day into a gross 660 KWe, in a very small footprint of about a quarter acre. The SynTech process accomplishes this through proprietary advanced gasification, not incineration or burning.”

The BioMax system is fully automated and can be controlled remotely from any location with internet access.

A growing global mandate exists for production of distributed, continuous and uninterrupted clean energy in the form of power, heat and liquid fuels. A similar mandate exists to produce more food from less ground without the harmful effects of chemical fertilizers. Nowhere is this more evident than in the surge in demand for organic produce. SynTech addresses these mandates while helping to solve some of the world’s greatest problems — diminishing natural resources, climate change, energy security, diminishing fresh water supplies, world hunger and increasing waste, just to name a few — and they do it by converting waste at the molecular level with advanced technologies.

SynTech, headquartered in Denver, Colorado, enjoys substantial competitive advantage over traditional renewable energy installations and both disrupts and displaces traditional, dirty and costly combustors, incinerators, digesters, biomass and pyrolysis equipment. SynTech complements recent advances in harnessing the power of wind and solar energy by providing uninterrupted base load power. No meaningful competition exists for SynTech’s products in the selected market spaces. Pent up global demand for distributed clean energy, waste remediation, environmentally friendly fertilizer creates an unprecedented market opportunity for biomass engineering. SynTech’s advanced gasification systems represent the most advanced waste-to-energy processes on the planet.

In addition to BioMax®, SynTechhas developed FluiMax® and LiquiMax® technologies. Together these technologies can remediate virtually any type of waste at any scale.

The FluiMax® advanced gasification technology is available in both 1-2.5MWe and 2.5-5MWe configurations and operates on anything from biomass to raw municipal solid waste, wheat and rice straw, bio-solids (wastewater, digester and animal) and a host of other environmentally problematic wastes. LiquiMax®, a proprietary Fischer-Tropsch gas to liquids micro-refinery technology, converts syngas, waste gases (landfill and wellhead flares, digesters, etc.) and pipeline gas into drop-in liquid transportation fuels (diesel, Jet A/B and JP8 military fuel), wax and other high value hydrocarbon liquids.

BioMax®, FluiMax® and LiquiMax® meet the most restrictive emission standards, are seamlessly interconnected with the grid and the customer, and do not harm the environment or use or produce water. All technologies are commercially deployed.