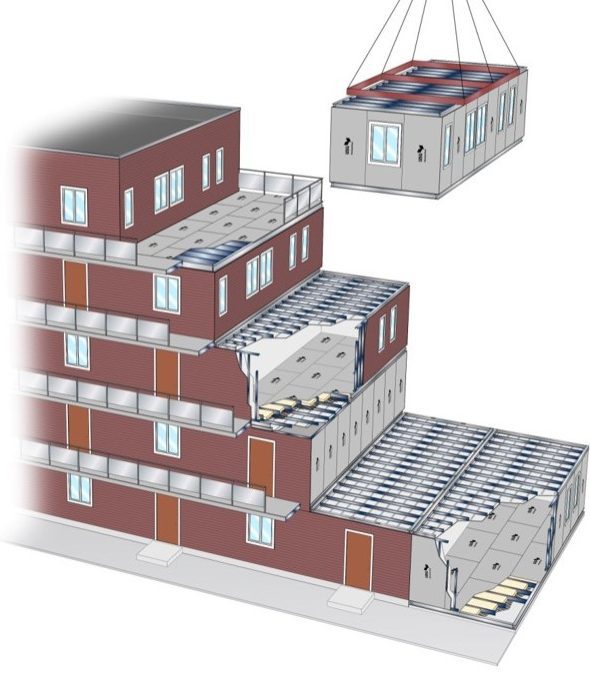

USG Introduces UL Design H501—First and Only 2-Hour Fire-Rated Design for the Modular Industry

CHICAGO – USG Corporation (NYSE:USG), a leading building materials manufacturer, introduces UL Design H501: a 2-hour fire-rated floor/ceiling assembly for permanent modular construction. The UL Design H501 uses USG Structural Panels instead of poured concrete, making it the thinnest UL-certified assembly for modular construction.

After identifying the types of challenges designers of noncombustible permanent modular buildings are presented with, USG Structural Solutions is delivering a system that evolves traditional practices; reduces construction time; lightens module weight; and offers unrivaled design flexibility—without compromising safety or local building codes.

“USG remains committed to providing customers ways to build faster and smarter. By developing the UL H501 system, we’re offering design flexibility that makes an immediate impact on reducing costs and shortening construction schedules,” said Jose Estrada, product marketing manager, Structural Solutions, USG Corporation. “We’re confident that with this system, and any product in our Structural Solutions portfolio, our customers will see a difference—even giving them an extra floor to work with when needed.”

Traditional use of poured concrete slabs for noncombustible permanent modular assemblies means that interior space is often sacrificed, and because concrete requires time to cure, production lines are slowed and can come to a halt.

The UL Design H501 has a minimum total system thickness of 12 5/8 inches, which allows room for taller interior ceiling space of the modules; or more floors on a building that’s limited to an overall height—without sacrificing floor/ceiling fire-resistance.

Additional Advantages of the UL Design H501 Modular Floor/Ceiling Assembly:

- Unrestrained assembly allows for larger open spaces

- Floor coverings and underlayments, while not part of the fire-resistance rating, are required for day-to-day use

- Primary structural elements (columns and beams) are part of the fire resistance design without the need for individual protection

Additional Benefits of USG Structural Panels:

- Less weight than poured concrete

- No pouring, setting or curing

- An alternative to poured concrete slabs for noncombustible permanent modular assemblies meeting ASTM E136-12

- Nonrotting, mold-, moisture- and termite-resistant

- Comply with VOC Emission requirements of California Department of Public Health CDPH/EHLB/Standard Method Version 1.1, 2010 (Emission testing method for CA Specification 01350)

For more information about USG Structural Panels, visit www.usg.com/modular.

About USG Corporation

USG Corporation is an industry-leading manufacturer of building products and innovative solutions. Headquartered in Chicago, USG serves construction markets around the world through its United States Gypsum Company and USG Interiors, LLC subsidiaries and its international subsidiaries, including its USG Boral Building Products joint venture. Its wall, ceiling, flooring, sheathing and roofing products provide the solutions that enable customers to build the outstanding spaces where people live, work and play. Its USG Boral Building Products joint venture is a leading plasterboard and ceilings producer across Asia, Australasia and the Middle East. For additional information, visit www.usg.com.