Safety Still First! BIM Takes Rule No. 1 to the Next Level

By John Turner

As the architecture, engineering, and construction (AEC) industry evolves, with new technologies leap-frogging our capabilities forward and shifting our approach to managing projects, there’s no aspect of the jobsite left untouched—and that includes safety. Innovative consultants are greatly impacting construction by leveraging new technologies to accomplish more. They’re reducing costs, streamlining schedules and improving safety—not just on the jobsite, but for the duration of a building’s life.

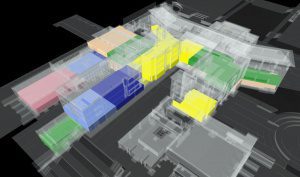

3D models enable a more-effective process of identifying and resolving potential safety issues in design.

Building Information Modeling (BIM) isn’t a new technology, but since becoming a trending topic in 2002, the industry has been swiftly discovering the distinct values BIM has to offer outside of clash detection. The industry also is beginning to witness a revolution in safety, where technology and human behavior intersect. Developers are finding that BIM’s 3D representation and cross-functional communication can dramatically improve safety in construction as well as final operation of built structures.

Transformational Change in 3D

Something as simple as a “what if” moment has spurred transformational change in how project consultants approach teamwork. Traditionally, the construction process hasn’t been structured to facilitate integration or collaboration: one entity designs the structure, another designs the mechanical system, while yet another constructs it—generally with poor communication. BIM has opened up a dialog between design entities, but what if BIM’s 3D visual environment were leveraged to bring collaboration to the next level?

The internet is rife with successful consultants bridging the gap between design and construction by bringing the contractor in during the design phase, but what about the facility personnel who have to operate and maintain the building when it’s complete? It’s the proactive, not reactive, approach the industry has been begging for.

The practical experience of the contractor in constructing complex facilities means they have a wealth of lessons learned to offer—experience that has a direct impact on bottom-line results to the project schedule and budget. The facilities team, however, also should participate. “Whole-team collaboration” earlier in the project can mitigate constructability challenges, simplify phasing, and design safety features into the construction process and final building.

Poor site coordination and stacking are significant contributors to jobsite accidents. Contractors can help designers identify safety hazards and safeguard against them, before the first piece of equipment touches the site. From fall protection to fire extinguishers, it’s difficult to ignore the demonstrated benefits of such a partnership. This is amplified with the involvement of facilities.

BIM analysis tools such as Solibri use the model to automate checks related to code compliance.

Resolving Hazards Before Construction

High-performing buildings integrate designs that focus on efficiency in operations and maintenance (O&M) costs, but BIM also can ensure they’re safe to maintain by taking proactive collaboration to the next level. During the design phase of a recent large project, for example, the owner’s representative decided to check the quality of the design to ensure the safety of its future O&M professionals.

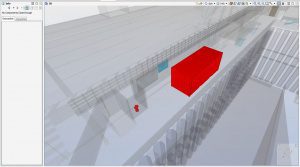

They modeled a simple task: using a scissor lift to replace HVAC filters. The model showed that the mechanical equipment was too high to access safely. Cable trays were impeding the scissor lift—there was no safe way for O&M to accomplish this simple task, although the design complied with the owner’s design criteria. To replace an HVAC filter, an O&M professional would have to stand on the second rung of the scissor lift’s railing for the filter to be within reach—an obviously unsafe task that would not be supported by the Occupational Safety & Health Administration. The owner’s representatives informed their clients, and the necessary design changes were made.

What’s needed to access a valve? How much space is needed in front of an electrical panel? Can a scissor lift turn in the space available? Can a filter be safely replaced? Can a pump, valve or motor be easily replaced? All of these questions can (and should be) answered and modeled during the initial design phase to ensure long-term efficiency and safety.

Due to BIM’s 3D capabilities, almost all maintenance tasks can be visualized within the system, making it easy to involve those who will be tasked with facility upkeep. By working with available O&M personnel, as well as utilizing a little common sense, hazardous tasks can be identified and eliminated.

A 4D analysis of a Pull-Planning schedule improves logistics planning, which has significant safety implications.

Those of us in the AEC industry can provide clients and communities more than a sound structure. We have an obligation to work together to ensure a structure is safe for those who construct, use and maintain it for many years to come. Working together, leveraging our expertise, we can deliver something that becomes more than just an office building or classroom—more than just a project. We can deliver environments that sustain and protect our communities.

About John Turner

John Turner is the vice president of Innovative Solutions at Gafcon; www.gafcon.com/team-view/john-turner.