Rethinking Rail Signal Design

Global consulting engineering firm Hatch Mott MacDonald had used a conventional CAD-based system to design rail signal systems when serving its public and private clients around the world. However, this approach had serious limitations in an industry where building information modeling (BIM), the processes and standards that define it, are becoming a critical success factor.

Traditional methods mean designs have no added intelligence or connections to related documents including bills of material (BOM). Designers have no way to model their work in 3D or collaborate on designs, which slows down projects unnecessarily and makes adherence to the required standards a challenge. As part of a wider BIM initiative, Hatch Mott MacDonald’s management chose to invest in a new system – powered by Bentley software – that introduced the required intelligence into the rail signal design process, significantly reducing design time and effort, improving accuracy, enabling collaboration, and driving standardization.

Hitting the Limits of Traditional Design Processes

Traditionally, signal designers at Hatch Mott MacDonald have used an in-house design workflow. While trusted and proven, procedures are manual, time-consuming, and tedious, and there are no automated controls to ensure the latest versions of CAD elements are used. In addition, design checking involves significant manual effort, everyone works sequentially, and there is little collaboration.

“3D design automation and the use of intelligent metadata within the design process is becoming the norm in many industries, including rail,” explained Hatch Mott MacDonald signal designer/Promis.e administrator Robert Henderson, C.Tech. “In order for Hatch Mott MacDonald to maintain its competitive edge, we understood that we must leverage industry best practice and the latest technology.”

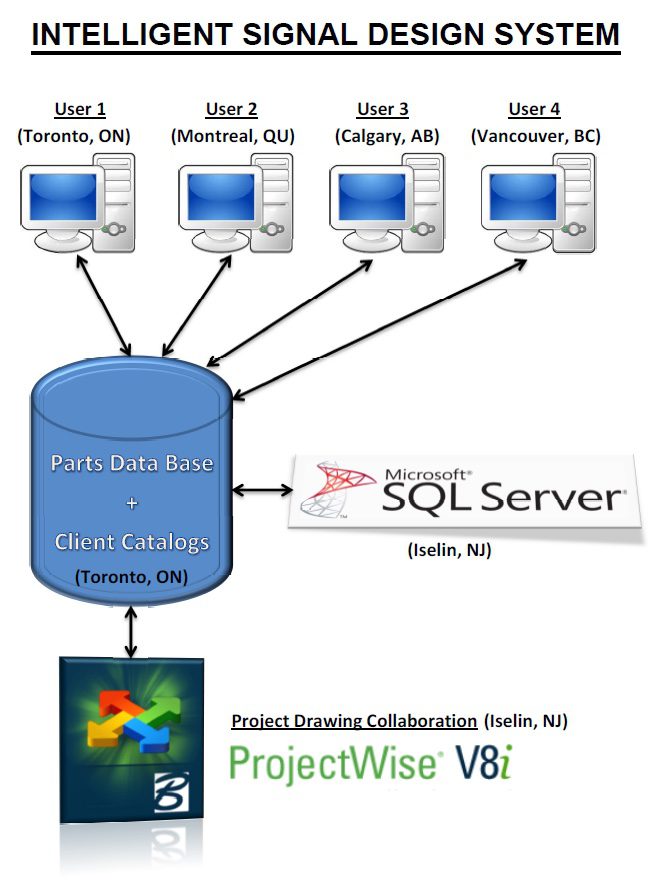

To stay ahead of the competition and meet the required Institute of Electrical and Electronics Engineers (IEEE) and International Electrotechnical Commission (IEC) standards, Hatch Mott MacDonald invested time to create a single database for project data and owner catalogs. Henderson added, “Promis.e has a comprehensive database and client catalog system for electrical disciplines, but our rail signals database had to be tailored to each railway’s independent standards for CAD and design.”

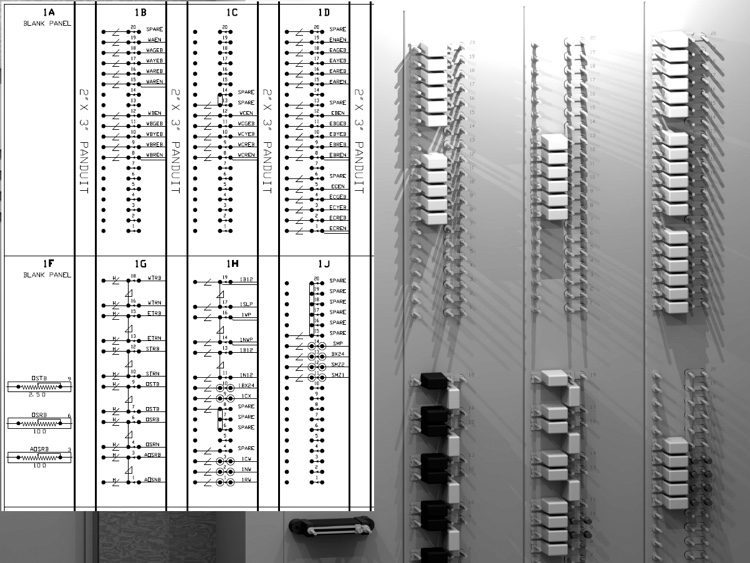

Hatch Mott MacDonald’s “single source of truth” for signaling parts and client catalogs available to all designers.

Harnessing the Latest Technologies

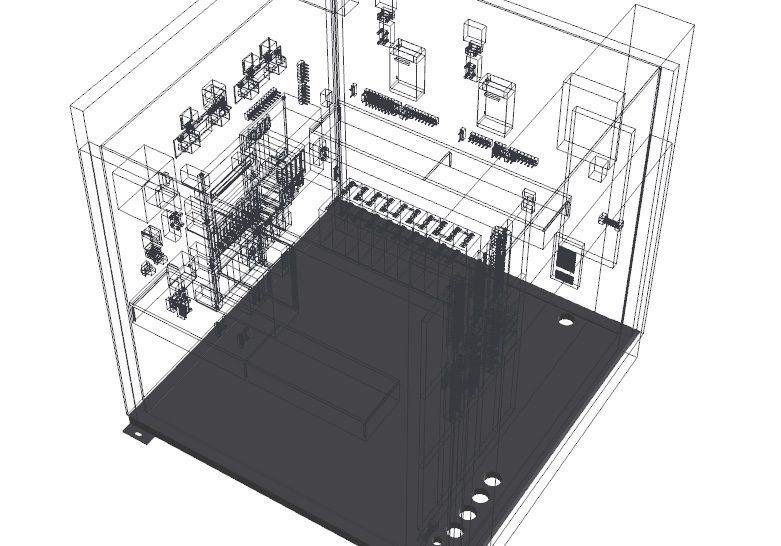

Using a combination of solutions from Bentley, Hatch Mott MacDonald works with intelligent 3D models linked directly to the electrical schematics required for signal design, costing, and construction. The new system includes functionality to automate the creation of project workflows via templates that will also streamline basic checking processes.

Leveraging the combined capabilities of Promis.e, Bentley Navigator, and ProjectWise®, Hatch Mott MacDonald will operationalize its intelligent system for rail signal design as follows:

- Content building – Using the Promis.e for Rail Signaling database, design teams can create schematic symbols that link directly to project databases and 3D layouts.

- Project building – Through an application programming interface (API), custom template scripts drive individual client standards, equipment selection, tag generation, schematic creation, and layout generation. As a result, designers simply input basic client and location information to arrive at an accurate, preliminary design that’s about 75 percent complete. The solution also ensures that owner-specific content created in the first step ripples through and is correctly used at every stage of the process.

- Engineering design considerations – Promis.e features automated checking tools that can be triggered by the designer. The system will perform a series of electrical circuit checks, verifying that users have not over-assigned the equipment’s electrical contacts, and ensuring that all tags have been generated. The rules that Promis.e’s engineering design considerations are based on are integrated with the existing Hatch Mott MacDonald Quality Environment and Safety (QES) standards.

- SQL Server and ProjectWise integration and roll-out- A significant element of the system is its integration with ProjectWise, enabling the sharing of project drawings. Multiple users can access the Promis.e project database, the “single source of truth,” through the SQL Server located at Hatch Mott MacDonald’s corporate headquarters.

Supporting a Whole New Way of Working

Bentley’s Promis.e adds intelligence into the Hatch Mott MacDonald’s design process using 2D schematics and 3D models, ensuring that designs conform to client standards as they progress. “As Promis.e users draw wires, they automatically populate databases with information that the software uses downstream in the design process. Users create wire tags and cable schedules without realizing it,” said Henderson.

The system allows designers to leverage information mobility to develop all client deliverables, and as a result, Hatch Mott MacDonald designs hold an abundance of information never before seen in rail signal design. With each component placed into a drawing, a bill of material is created automatically along with associated project estimates and updated budgets. The solution significantly reduces design time, improves accuracy, and enables both collaboration and standardization across projects.

BIM Delivers Downstream Value

The BIM methodology also provides the potential for information gathered during the planning and design phase to feed and combine with an additional project and asset data collected during construction, and deliver greater value downstream. Spatial and contextual information that might include design codes used and current legislation can be used during construction to accurately define and record what has been built on site and, therefore, requires maintenance into the future.

For owner operators, access to this type of information, which might include anything from size and location to manufacturer, performance, and power consumption of a piece of equipment, is business critical. Henderson added, “Eventually, all equipment will need upgrading or replacement. New components must conform to all the original requirements and current legislation. Without access to information you can trust, wherever and whenever you need it, it becomes very difficult to effectively and efficiently operate and maintain the asset.”

Realizing the Benefits

Hatch Mott MacDonald has started to see a return on investment in terms of quality, flexibility, and interdisciplinary operability. “Using this technology will allow us to drive our already-very-high level of quality to a level that just can’t be matched,” said Henderson. “We can also react to scope and design changes with relative ease, and to a degree not seen anywhere else in this industry.”

Hatch Mott MacDonald expects a 50 percent reduction in time spent on the first level of its design workflow, which will translate into a 20 percent cost reduction at modular design locations. Modular designs typically account for roughly 80 percent of the overall design plan sets on a given project. The automation tools apply site-specific information and equipment virtually eliminating the human error factor associated with the repetitive work within standard CAD template. Henderson commented “an additional 25 percent reduction in design checking time during the second level of the design process is expected, which will translate into a 28 percent cost reduction. Add in the time saved by automating a project’s BOM, and given that a large signaling project could include up to 200 design locations, the potential overall cost reduction of up to 35 percent per rail signal design location is significant.”

Integrated Apps Promote Innovative Offering Hatch Mott MacDonald also explored the use of Bentley Navigator, Navigator Mobile, and ProjectWise Worksite within the team to review, analyze, and communicate its designs through i-models. Project stakeholders can use i-models to share information across the team securely and accurately. As well as enabling greater project insight, the use of integrated apps allows Hatch Mott MacDonald to further demonstrate the value of its innovative offering to existing and potential clients using iPads for fieldwork and the potential for new or non-traditional deliverables.

Hatch Mott MacDonald’s practice leader rail and transit, Nathan Higgins, P Eng, PE, PMP, said “Bentley’s Promis.e has enabled Hatch Mott MacDonald to make a paradigm shift in design methodology, thereby saving owners time and money while providing innovative services and ensuring quality.” In addition, by integrating rail signal designs with the 3D civil engineering design models, the company can achieve its goal of moving toward a multi-disciplinary design process in a 3D framework – and ultimately to a 5D framework that incorporates time and cost.

About Steve Cockerell

Steve Cockerell joined Bentley Systems in 2002 through the company’s acquisition of Infrasoft, and has since worked as part of a team delivering knowledge and expertise to its users in the transportation industry. Cockerell has more than 20 years of industry experience, which he began by studying civil engineering and working as a highway designer for local government in the U.K. He joined MOSS Systems in 1990 as an application engineer demonstrating functionality and highlighting the benefits delivered by CAD-based design applications for highways, rail, and land development projects. Following Infrasoft’s acquisition of MOSS Systems, Cockerell served as channel marketing director where he helped develop and launch Arenium, an engineering collaboration product that enabled multi-user access to MX 3D design models. This paved the way for technology that supports building information modelling processes now demanded by industry and governments around the world.