The Internet of Things: Coming to Facility Systems Near You!

Bob Dylan’s iconic song, “The Times They Are A-Changin’,” still rings true for many things, including building infrastructure management. And the melody of change is the Internet of Things (IoT), which is facilitating smart city planning and smart home devices.

IoT is integrated building automation on steroids. It’s resilient buildings; sustainable buildings. It’s building intelligence.

Specifically, it’s a digital revolution that empowers facilities executives to relieve their “pain points,” improving reliability and efficiency, ensuring operational continuity, managing the increasing complexity of buildings, merging legacy buildings and their systems with facility expansions, maintaining aging infrastructure, and improving reporting and compliance. And let’s not forget to “do more with less.”

Those embracing the revolution know about operational issues sooner, make decisions faster and take action more insightfully. Adapting to change is inevitable, even unavoidable. The inescapable truth is that building infrastructure management as a professional discipline needs and wants the change.

Mike Wiruth checks the status of automatic transfer switches at Bryan Medical Center in Lincoln, Neb.

IIoT Redefined

If IoT is the Internet of Things, IIoT typically refers to the Industrial Internet of Things. But there’s a better use of the acronym: Infrastructure Internet of Things. It’s at the infrastructure level where IoT can bring sweeping change to building management.

IIoT integrates data-gathering sensors with compute capability into a range of infrastructure devices, components and systems that communicate wirelessly via the Internet or a central computer. The sensors have local intelligence and compatible, two-way communication pathways and streamlined network topology protocols.

A consumer example is home lighting that can be turned on and off with a smartphone from anywhere outside the home. A more sophisticated example is the Bill Gates mansion in Washington state. Guests wear pins that help automatically adjust temperature, music and lighting based on their preferences as they go from room to room.

In commercial, institutional and government buildings, typical IIoT examples range from HVAC and lighting to building management and critical power management systems (CPMS). In these applications, sensors stream data to highly specialized and hyper-fast software that aggregate, analyze, store and possibly act autonomously on the data, without human intervention. Or the programs can be remotely controlled and interact with facility personnel when necessary.

They adjust to their environments or operating conditions. Rather than run to failure, they call for maintenance. Ideally, they modify their operation to accommodate for wear or other issues, then alert related machines and operations staff responsible for them. In time, IIoT could penetrate nearly every aspect of infrastructure.

Proactively managing such operations is especially useful when failure of critical infrastructure systems can cause catastrophic consequences to manufacturing, back- and front-office operations and, specifically, IT functions. For critical power, for example, monitoring and controlling today’s complex infrastructure with precision, accuracy and reliability can mean the difference between a potentially catastrophic power outage or “business as usual.” There are no second chances when business-critical continuity matters.

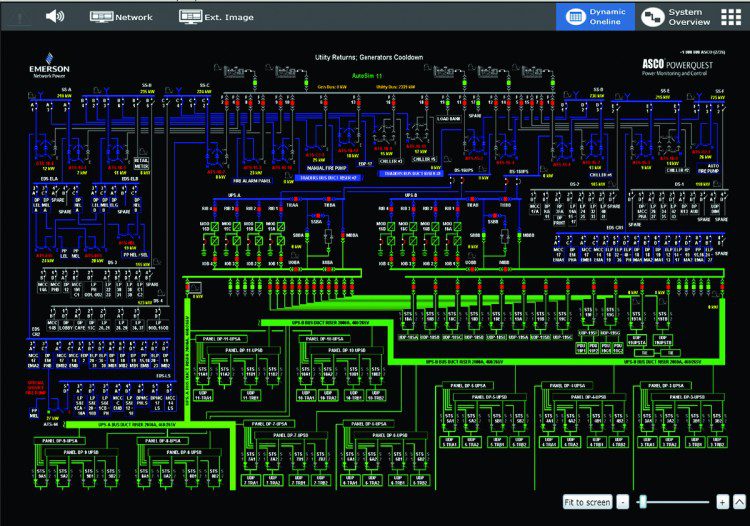

CPM systems in multiple locations can be monitored and controlled from a single control center.

By the Numbers

The overall magnitude of change can be mind boggling. Some of the planet’s most respected business research firms have weighed in on the enormous potential offered by basic IoT.

International Data Corp. estimated that organizations spent $113 billion worldwide in 2013 on relevant information management, access, and analysis technologies and services.

ABI Research data indicate there are more than 10 billion wirelessly connected devices installed today.

Gartner projects about 25 billion connected devices by the end of this decade, and McKinsey Global Institute and the National Intelligence Council (NIC) consider IoT a “disruptive” technology. McKinsey reported that IoT could potentially generate an economic impact of $2.7 trillion-$6.2 trillion annually by 2025. An NIC report, “Disruptive Civil Technologies, Six Technologies with Potential Impacts on U.S. Interests out to 2025,” included a number of scenarios describing the timing and depth of IoT market penetration.

The more aggressive scenarios seem to be materializing. General Electric’s 2012 report, “Industrial Internet: Pushing the Boundaries of Minds and Machines,” sets the value at up to $32.2 trillion, leading to a $10 trillion-$15 trillion jump in global GDP during the next 20 years.

Taken together, the array of sensors in buildings creates interconnected building infrastructure management systems called “clusters,” which can comprise hundreds or thousands of sensing devices on related equipment. They could be part of an infrastructure for a single building, multi-building campus or multiple locations worldwide. Natural clusters are HVAC, safety, security and CPM.

A power-control center can simultaneously display, monitor and manage multiple CPM systems.

Into an Ecosystem Will a Cluster Grow

In general, clusters integrate legacy equipment and new technologies into an interoperable, distributed “ecosystem,” which is an array of equipment, devices and components designed to work with each other.

Apple, for example, created an ecosystem of iProducts. Someone who has an Apple iPhone, iPad, accessories and apps designed for them is unlikely to switch to an Android ecosystem. Blackberry, by comparison, didn’t develop a successful ecosystem and lost customers in droves. It didn’t adapt to its market’s digital revolution.

In a CPM ecosystem, integrated communications, sensing and measurement, advanced control, improved interfaces and decision-support technologies, and sophisticated power analytics help manage power-distribution infrastructures more efficiently. This type of smart infrastructure adapts to, and anticipates, building managers’ needs, and can proactively manage critical power within established parameters.

CPM infrastructures promise a range of capabilities that could satisfy virtually any need. But what capabilities do facilities decision makers really want?

ASCO Power sponsored a National Power Monitoring & Control Survey of 15,000 facility-management decision makers that shed light on the capabilities they have as well as those they want.

Building infrastructure managers will see more data than ever before, and they’ll be expected to interpret them quickly. This is important, because data can be their best friend or worst enemy.

More than two-thirds of respondents have, or would like to have, monitoring capability from their CPM infrastructure. More than half have, or need, control and reporting capabilities.

Almost half of those with control and reporting capabilities also have some sort of integrated system to manage it. About 45 percent of respondents have some type of power-quality monitoring and analytics. There’s obviously room to improve.

Big Data

The result of cluster management—sensors on almost all devices and the IIoT that pulls everything together—is Big Data. A single industrial machine, for instance, can produce 1TB of data hourly.

Building infrastructure managers will see more data than ever before, and they’ll be expected to interpret them quickly. This is important, because data can be their best friend or worst enemy.

According to Richard Soley, executive director of the Industrial Internet Consortium, “For end users, real-time analytics becomes the basis for information-based decision making.”

Interpretation is what makes facility-management data valuable, because then they can be monetized, curated, analyzed, interpreted and shared.

For CPM infrastructure, Big Data is a change agent for reducing energy consumption, projecting capacity requirements, streamlining maintenance, resolving operational issues and meeting reporting requirements.

To be truly useful, however, Big Data need to be fingertip available. The solution is dynamic visualization, which enables operators to assimilate, decide and act on data at a moment’s notice. Dynamic visualization relies on the human brain’s ability to process information in visual terms faster than it can alphanumerically, presenting constantly changing data graphically, schematically and pictorially—not in words and reams of raw numbers. Dynamic visualization of an electrical one-line, for example, shows power flow, which facilitates identification, diagnosis and issue resolution. It enhances the utility, and therefore value, of Big Data.

Effectively visualizing information makes data more predictable and enhances productivity. Data analytics also averts issues via real-time trending, which helps identify insights into process operations, such as bottlenecking and quality issues. Data analytics also can supplant running reports that reflect a “point-in-time” picture that satisfies compliance reports but may not accurately represent a process’ “as-is” status.

Data analytics for CPM infrastructure typically focus on power quality. Such analytics help optimize infrastructure operational reliability by monitoring power issues and helping operators correctly diagnose the real problem so it can be quickly resolved.

The ability to analyze, diagnose and act, from operator and machine perspectives, improves asset management. Operational efficiency, reliability and predictive maintenance all benefit.

What’s valuable needs to be secured, so protecting Big Data ought to be an essential element of an IIoT-enabled cluster.

Real-Life Results

Building-infrastructure managers at two hospitals and a top-10 investment bank are living the IIoT dream. Chris Liedman at Park Nicollet Methodist Hospital in Minnesota, realizes the value of precision, accuracy and reliability of an IIoT-based CPM and control system.

“The big win for us is automated reporting and trending,” says Liedman. “Before, everything was handwritten. Now we generate reports tailored to meet the requirements of healthcare facilities, so they’re perfect for our monthly run report.”

Dynamically visualizing a CPM system helps operators quickly and easily assimilate data.

Data trending shows power-demand history, so managers know where they have adequate capacity and, more importantly, where they don’t. Users overlay such data with future construction plans, which help project CPM scaling to keep it in lockstep with hospital growth and energy demand.

Another convert to the digital revolution is Mike Wiruth at the Bryan Medical Center in Lincoln, Neb. New CPM capabilities enable him to view the status and testing of critical power from a single computer screen. Automatic email alerts and reports have proven to be one of the biggest plusses, because gen-sets and transfer switches are in parts of buildings with no people.

“When a generator starts or a load transfers anywhere on campus, I know it,” notes Wiruth. “When I was on vacation, my partner did a ‘no-load’ test, and I received an email telling me it was done.”

The digital revolution in CPM infrastructure also benefits a top-10 global-investment banking firm that remotely operates an onsite power system at one of its trading and data centers nearly 900 miles from the firm’s power-control center in New Jersey.

Web-client-enabled CPM capabilities allow the team at the control center to monitor and operate the entire power chain at the firm’s Nashville, Tenn., office 24/7. Top-to-bottom monitoring of the facility’s power chain encompasses data-center load density, power-usage efficiency, power quality, energy-management systems, alarms, uninterruptible power systems, and a battery-monitoring and prognostic interface.

IIoT-based infrastructure changes the way managers work as well as with whom they work. They may be working with a new C-level executive: the chief digital officer (CDO). Consider that by the end of 2015, a quarter of all organizations could have a CDO, who will develop a strategy for integrating the digital revolution within the organization, and help empower operations and engineering managers to implement it.

Embracing IIoT will help alleviate a number of “pain points” and enable users to know, decide and take action confidently. For those who don’t, Bob Dylan’s advice was “Then you better start swimmin’, or you’ll sink like a stone.”

About James Huckfeldt

James Huckfeldt is president of First Team Marketing, a communications firm specializing in infrastructure systems, particularly power generation and management, lighting and HVAC.