BIM-Enabled Digital Fabrication of Structural Steel – An Advanced Approach

Complete and real benefits of BIM can be extracted only when it is used across all the aspects of a construction process and beyond. Today, a lot of firms have adopted BIM for project planning, scheduling, cost estimation facility management, etc.

However, why does it happen that the overall productivity rates of the projects still continue to fall? This is because, although a BIM approach is implemented across all these stages of building design and construction, they still miss out on the most important aspect of construction i.e. Building Information Models for Digital Fabrication.

BIM Workflow For Steel Fabrication

Building information modeling enables projects to adopt digital design to fabrication workflows for structural steel. Just like Mechanical CAD models are used for various types of simulations and analysis that allow improved manufacturing process, BIM models can be used to automate building construction process. A building itself is not manufactured, however, there are several structural parts like doors, windows, pre-stressed concrete and structural steel, that needs to be manufactured/prefabricated and then assembled on site.

Conventionally shop drawings are used for steel fabrication. Now, the number of shop drawings required for a building project is far more than the number of construction drawings. For digital fabrication, all these manual shop drawings are created using steel detailing software. A building information model that carries all the details and shop drawings required for steel detailing and fabrication can be fed into the structural fabrication process.

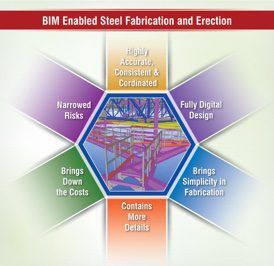

Benefits of BIM-Enabled Steel Fabrication and Erection

The use of VDC – Virtual Design and Construction capabilities enables a fully digital design to fabrication process for steel structures. Now this process is highly efficient because BIM provides a fully digitized design data that is highly accurate, consistent and coordinated. The fabrication models can also be further used for 4D modeling and clash detection. This fabrication model contains more details than the regular structural models used for BIM, and hence can be used for interference checking in buildings where the fittings have to be extremely tight with no scope for gaps.

Another advantage of BIM is that, it helps bring simplicity in fabrication, and hence considerably brings down the costs of fabrication and erection. Also using the design model for fabrication; brings design and fabrication considerations from the fabricators point of view to the fore. In addition, the fabricated steel components coordinate with other building components as predicted and hence the risk of furthermore discrepancies or clashes are narrowed down to zero. Hence the rising costs of steel erection can be curbed.

What drives home the point is the fact that collaboration between structural engineer, steel detailer and the fabricator is one of the important factor that leads to a succesfful and efficient design, fabrication and erection of steel structures. Now this coordination can be enabled in the best manner only via BIM implementation and its adoption for digital fabrication. How? While earlier these three i.e. the design, detail and fabricate were steps that occoured in succession, today with Revit BIM and Digital Fabrication, they can be done more concurently.

The design model and shop drawings can be created in sync with each other simulataniously, and hence the time can be saved. When design model and shop drawings both are prepared sooner than usual, naturally the following process also starts early and hence is completed early. As a result the steel structure can also be erected early.

To sum it up we can say that use of BIM for steel fabrication and erection bolsters up the process on all three fronts, i.e. quality, cost and time. What else can you ask for?

About Bhushan Avsatthi

Bhushan Avsatthi is an Associate Director at Hi-Tech Outsourcing Services. Bhushan is a Consultant, BIM expert and a green building advisor with more than 15 years of industry experience. Bhushan imbibes the prophecy of efficient and prudent use of energy in his day to day life and advices his team to do so as well. He is also involved in green initiatives like nonprofit tree plantation project and promotes using bicycles for commuting small distances. Bhushan, handles a team of architects, structural and MEP engineers, LEED consultants and energy modeling experts.